A high-strength multi-layer composite structure agricultural mulch film and its preparation method

A multi-layer composite, agricultural mulching film technology, applied in the directions of botanical equipment and methods, chemical instruments and methods, applications, etc., can solve the problems of poor stretching, tearing and other properties, affecting service life, slow growth of crops, etc. Achieve the effect of good reflection, high tensile strength and obvious soil cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

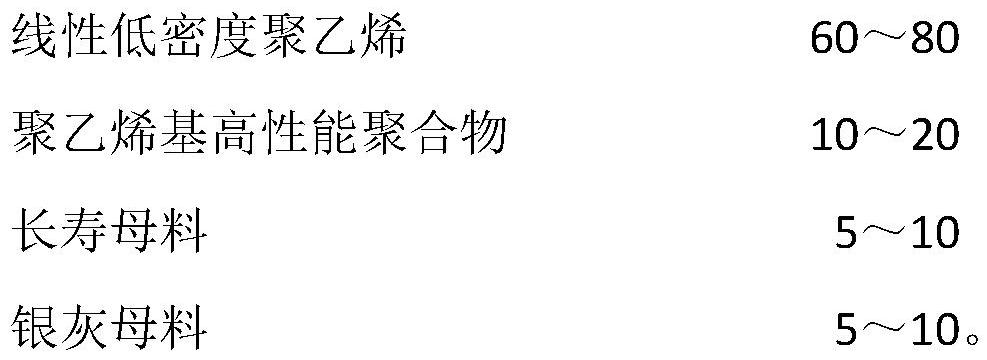

[0033] The raw materials for the preparation of the silver-gray mulch layer, in parts by weight, include

[0034]

[0035]The linear low-density polyethylene described in the present invention is ethylene as the main raw material, and a small amount of α-olefins (such as butene-1, octene-1, etc.) are obtained by gas-phase fluidized bed polymerization under high pressure or low pressure under the action of a catalyst polymers, wherein the catalyst does not include metallocene catalysts, that is, in the present invention, unless otherwise specifically emphasized, the "linear low-density polyethylene" refers to linear low-density polyethylene excluding metallocene polyethylene . Compared with conventional polyethylene, linear low-density polyethylene has a small amount of short-chain branches on the molecular chain, and has a higher degree of linearity, so it has a more regular molecular arrangement, greater crystallinity and heat resistance.

[0036] In some embodiments, the...

Embodiment 1

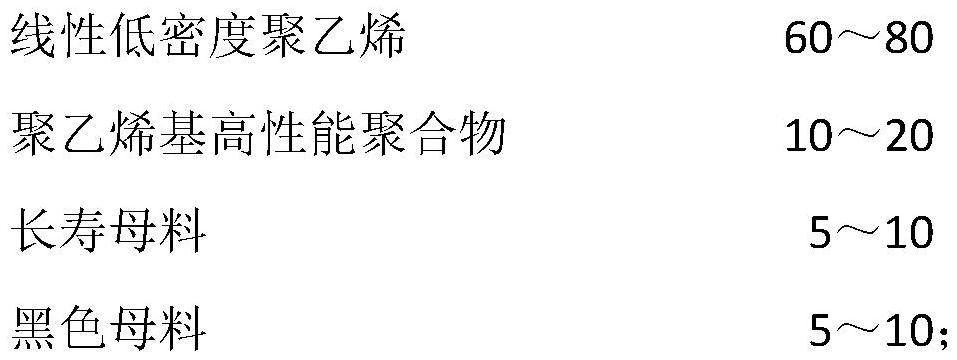

[0060] Embodiment 1 provides a kind of high-strength multilayer composite structure agricultural mulching film, including silver-gray mulching layer and black mulching layer; The preparation raw material of described black mulching layer, by weight part, comprises:

[0061]

[0062]

[0063] The raw materials for the preparation of the silver-gray mulch layer, in parts by weight, include

[0064]

[0065] Described linear low-density polyethylene is the product (melt index is 2.0g / 10min, and density is 0.918g / cm2) that ExxonMobil brand is LL1002 3 ); the polyethylene-based high-performance polymer is Exceed XP series product of Exxon Mobil Corporation, which is XP6026ML (density is 0.916g / m 3, melt index is 0.2g / 10min); the long-life masterbatch is prepared by resin carrier, anti-aging agent and functional auxiliary agent; the resin carrier is obtained by blending low-density polyethylene and ethylene-vinyl acetate copolymer, which The weight ratio is 3.6:1; the ethy...

Embodiment 2

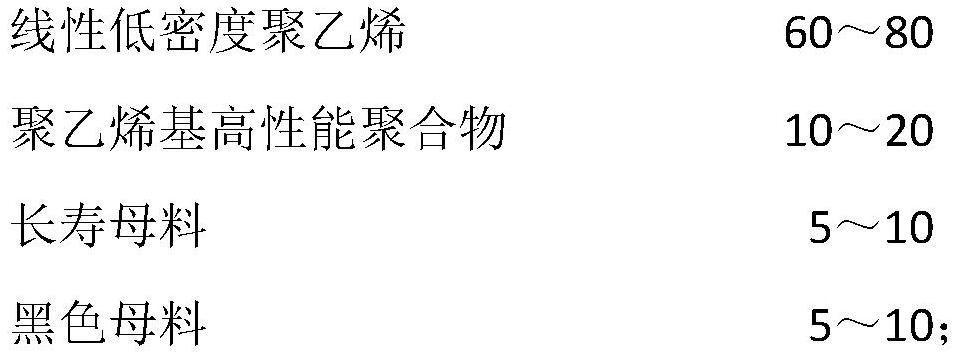

[0071] Embodiment 2 provides a kind of high-strength multilayer composite structure agricultural mulching film, including silver-gray mulching layer and black mulching layer; The preparation raw material of described black mulching layer, by weight, comprises:

[0072]

[0073] The raw materials for the preparation of the silver-gray mulch layer, in parts by weight, include

[0074]

[0075] Described linear low density polyethylene is the product (melt index is 2.0g / 10min, and density is 0.918g / cm 3 ); the polyethylene-based high-performance polymer is a product of Exceed XP series brand of Exxon Mobil Corporation, which is XP6026ML; the long-life masterbatch is prepared from a resin carrier, an anti-aging agent and a functional auxiliary agent; the resin carrier is made of Low-density polyethylene and ethylene-vinyl acetate copolymer are blended, and the weight ratio is 5:1; the ethylene-vinyl acetate copolymer is ExxonMobil brand ethylene-vinyl acetate copolymer (VA c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com