A kind of high-strength three-layer two-color agricultural mulch film and its preparation method

A two-color mulch, high-strength technology, applied in botany equipment and methods, chemical instruments and methods, applications, etc., can solve the problems of farmland residual film pollution, easy aging and rotten film, clean up, etc., and achieve obvious soil cooling effect, Strong ability to resist wind and sand damage and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The raw materials for the preparation of the middle layer, in parts by weight, include:

[0045] Linear density polyethylene 80~90

[0046] Polyethylene-based high performance polymer 5~10

[0047] White masterbatch 5~10;

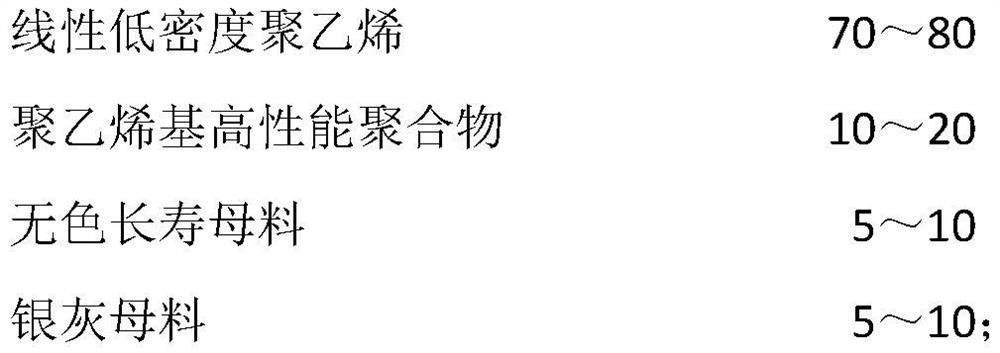

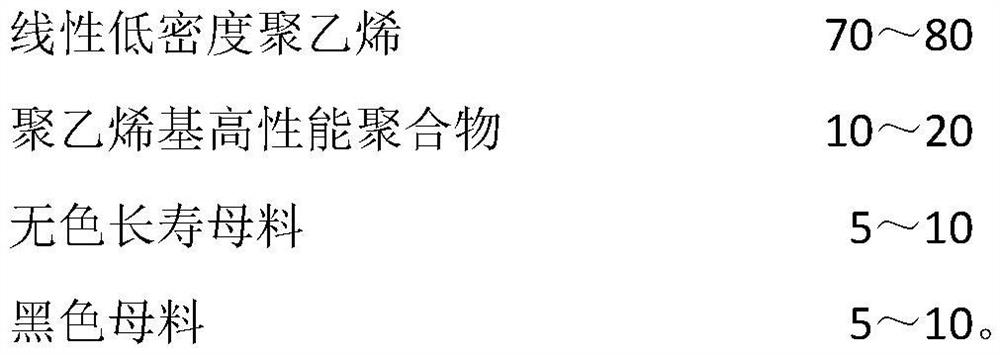

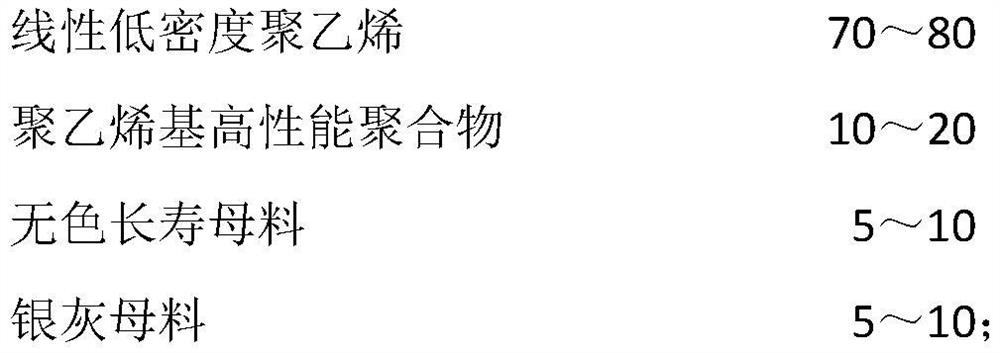

[0048] The raw materials for the preparation of the inner layer, in parts by weight, include:

[0049]

[0050] In some embodiments, the content of the white masterbatch accounts for 4-11wt% of the weight of the raw materials for preparing the middle layer; the white masterbatch contains titanium dioxide.

[0051] The white masterbatch containing titanium dioxide is used in the middle layer of the mulch film in the present invention, and the middle layer can strengthen the outer layer of the mulch film, so that the strength and aging resistance of the mulch film can be further strengthened, and the surface (silver gray surface) of the mulch film can be improved at the same time. For the emission of light, the infrared light in the light is emit...

Embodiment 1

[0071] Embodiment 1 provides a high-strength three-layer two-color mulch film, the high-strength three-layer two-color mulch film is a three-layer composite structure made by a co-extrusion blown shed film unit, including an inner layer, a middle layer and an outer layer; The raw materials for the preparation of the outer layer, in parts by weight, include:

[0072]

[0073] The raw materials for the preparation of the middle layer, in parts by weight, include:

[0074] Linear density polyethylene 80

[0075] Polyethylene-based high-performance polymers 5

[0076] White masterbatch 5;

[0077] The raw materials for the preparation of the inner layer, in parts by weight, include:

[0078]

[0079] The linear low density polyethylene Exxon Mobil brand is the product of LL-3001 (melt index is 1.5g / 10min, density is 0.917g / cm 3 ); the polyethylene-based high-performance polymer is the product of XP6026ML (melt index is 0.2g / 10min, density is 0.916g / cm 3 ); the colorless...

Embodiment 2

[0088] Embodiment 2 provides a high-strength three-layer two-color mulch film, the high-strength three-layer two-color mulch film is a three-layer composite structure made by a co-extrusion blown shed film unit, including an inner layer, a middle layer and an outer layer; The raw materials for the preparation of the outer layer, in parts by weight, include:

[0089]

[0090] The raw materials for the preparation of the middle layer, in parts by weight, include:

[0091] Linear density polyethylene 90

[0092] Polyethylene-based high-performance polymers 10

[0093] White masterbatch 10;

[0094] The raw materials for the preparation of the inner layer, in parts by weight, include:

[0095]

[0096] The linear low density polyethylene Exxon Mobil brand is the product of LL-3001 (melt index is 1.5g / 10min, density is 0.917g / cm 3 ); the polyethylene-based high-performance polymer is the product of XP6026ML (melt index is 0.2g / 10min, density is 0.916g / cm 3 ); the colorle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com