Lead methanesulfonate flow battery electrolyte

A technology of lead methanesulfonate and flow batteries, which is applied in the application field of electrolyte additives and lead methanesulfonate flow batteries, can solve the problems of short cycle life, extend the life of anodes, and improve electrocatalysis Effects of activity and stability, improvement of Coulombic efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare the electrolyte for a lead methanesulfonate flow battery in a fume hood:

[0034] 1) Slowly add deionized water to CH 3 SO 3 Diluted in H, then in PbCO 3 Add a small amount of deionized water to dilute the CH 3 SO 3 H slowly added to PbCO 3 in the aqueous solution and keep stirring until the reaction is complete, and then add deionized water to dilute the electrolyte solution without additives; where (CH 3 SO 3 ) 2 Pb is 1.8mol:CH 3 SO 3H is 0.3mol, 1L in total.

[0035] 2) Pour them into two 500ml electrolyte bottles on average.

[0036] A Electrolyte: Add 0.005 mol of NaF to the 500ml electrolyte prepared just now, stir evenly, and use it as the electrolyte of the lead methanesulfonate flow battery.

[0037] B Electrolyte: No additives are added.

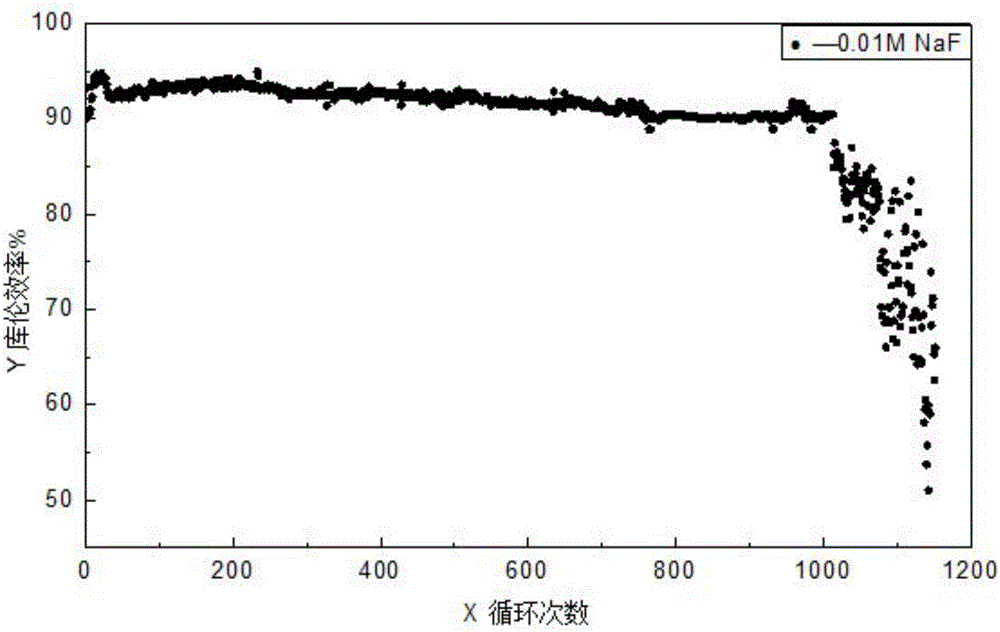

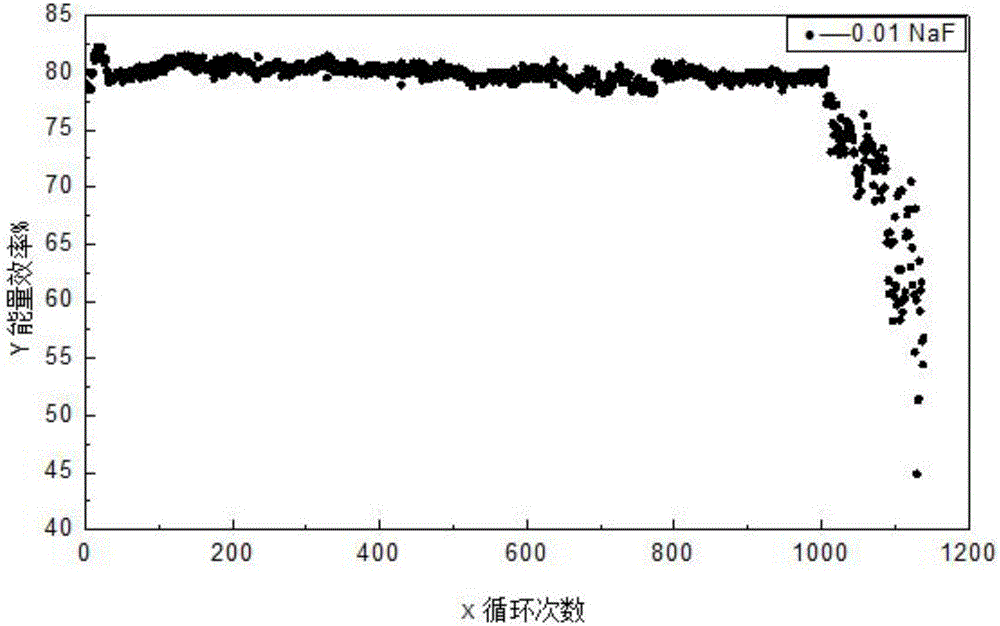

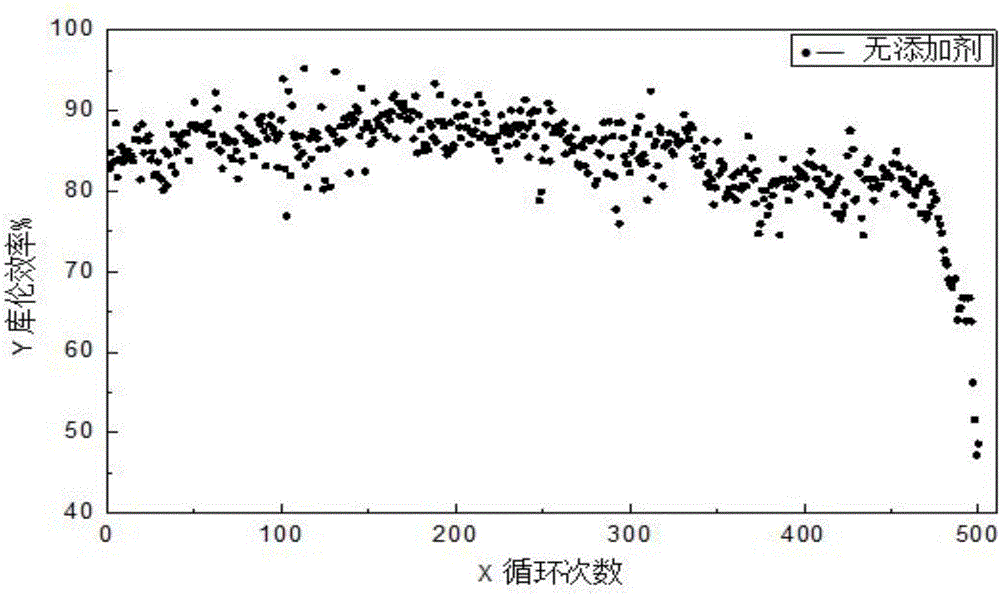

[0038] The lead methanesulfonate flow battery is assembled according to the above method, connected with A, B electrolyte and pump pipes, and fully tested. Parameter setting of charge and discharge test...

Embodiment 2

[0040] Prepare the electrolyte of lead methanesulfonate flow battery in fume hood: method is the same as embodiment 1, wherein (CH 3 SO 3 ) 2 Pb:CH 3 SO 3 H=1.5:0.9(M), 1L in total.

[0041] Pour into two 500ml electrolyte bottles respectively.

[0042] C Electrolyte: Add 0.0075 mol of NaF to the electrolyte prepared just now, stir evenly, and use it as the electrolyte of the lead methanesulfonate flow battery.

[0043] D Electrolyte: No additives are added.

[0044] The lead methanesulfonate flow battery was assembled in the above-mentioned manner, connected with C, D electrolytes and pump tubes, and fully tested. Parameter setting of charge and discharge test: charge and discharge current density is 10mA / cm 2 , The charging time is 2h, and the linear flow velocity of the electrolyte in the battery is 0.5-5cm / s. The results show that the Coulombic efficiency of the C cell is 90-91%, and the energy efficiency is 74-77%. D cells have a Coulombic efficiency of 70-90% an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com