Redundant drive system

A technology of drive system and oil supply system, which is applied in control systems, motor vehicles, electric vehicles, etc., can solve the problems of high cost and cost increase, and achieve the effect of low cost and improved failure reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

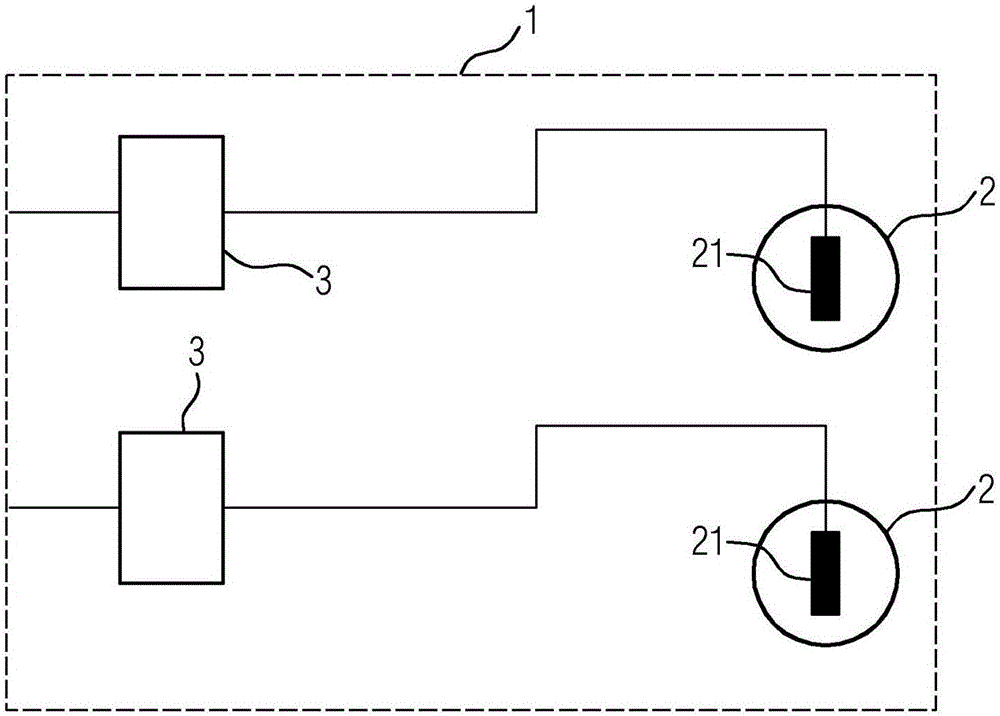

[0031] figure 1 A known drive system 1 is shown. It has two inverters 3 and two motors 2 . The engine 2 in turn contains a winding system 21 . The motors 2 are each fed via separate inverters 3 . Although motor 2 can be individually controlled open-loop or closed-loop by this arrangement, failure of inverter 3 has the result that motor 2 connected to it also fails and is therefore no longer able to provide torque. Group drives are also known, in which one inverter 3 supplies several motors 2 . Although this is better than figure 1 The configuration shown is less expensive, but the open-loop or closed-loop controllability of the individual motors 2 is lost in this group drive.

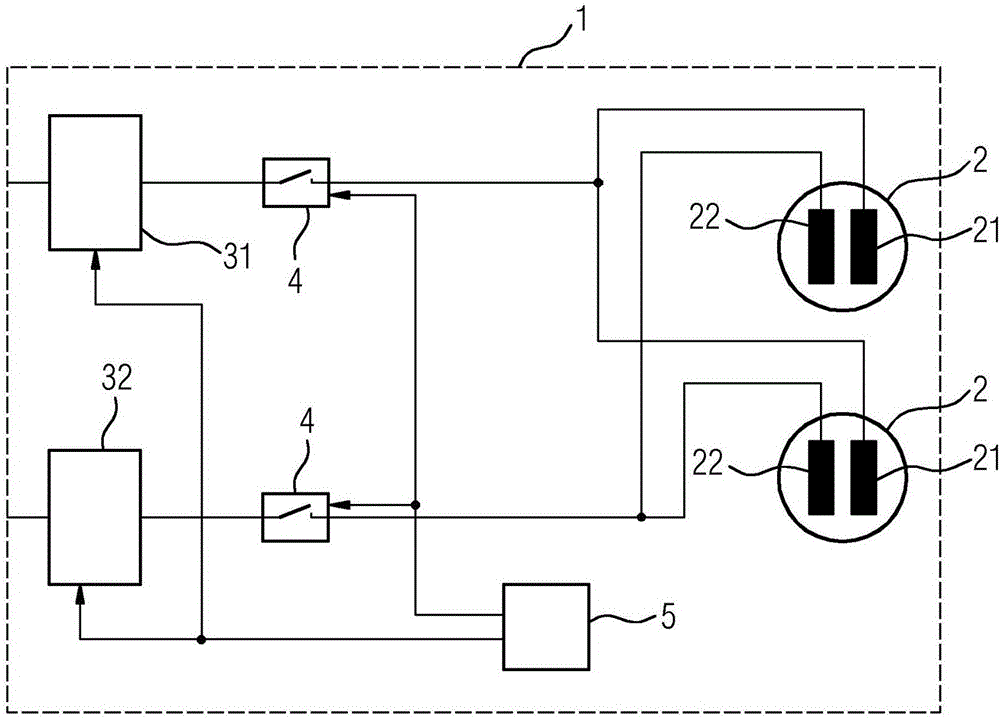

[0032] figure 2 A drive system 1 according to the invention is shown with two inverters 31 , 32 , two motors 2 , and a switch 4 at the output of the inverters 31 , 32 each and a central regulating device 5 . The central regulating device 5 can be implemented separately or integrated in one of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com