Method for operating a two-stroke otto engine

An Otto engine, two-stroke technology, applied in the direction of engine components, engine control, combustion engine, etc., to achieve uniform heat distribution and reduce the risk of carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

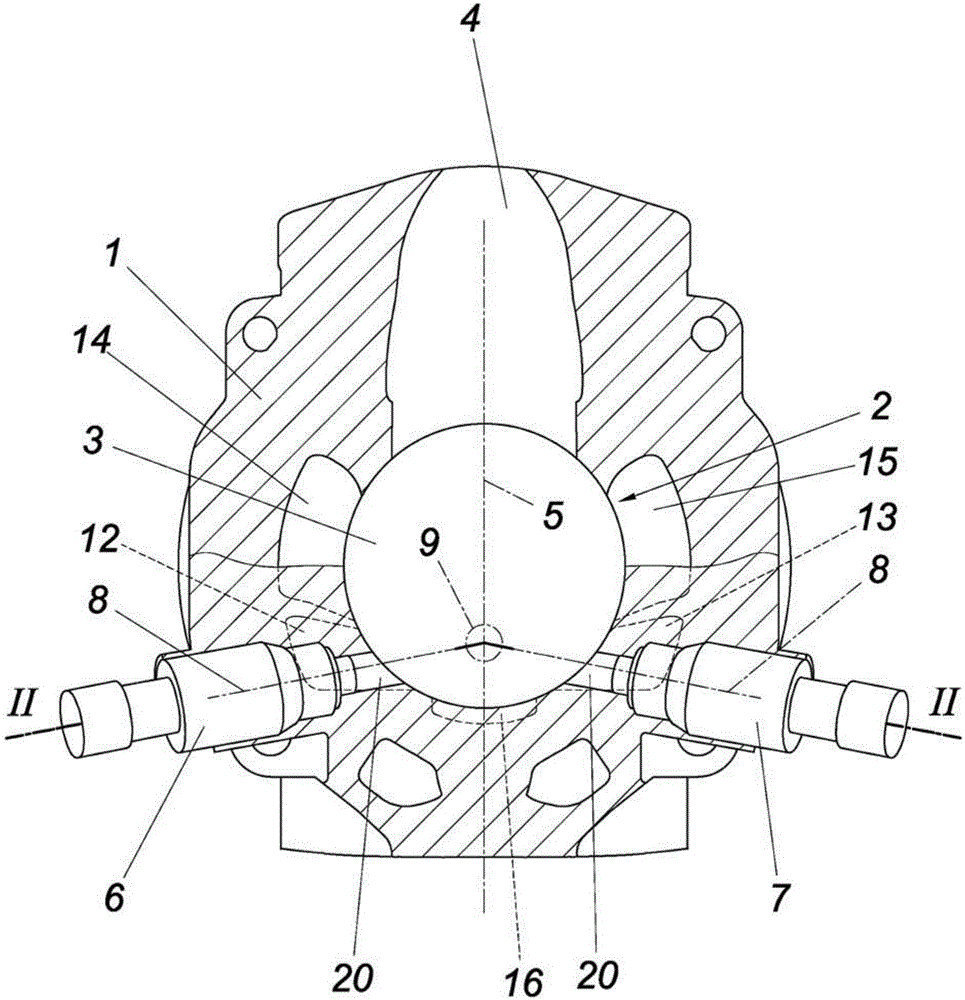

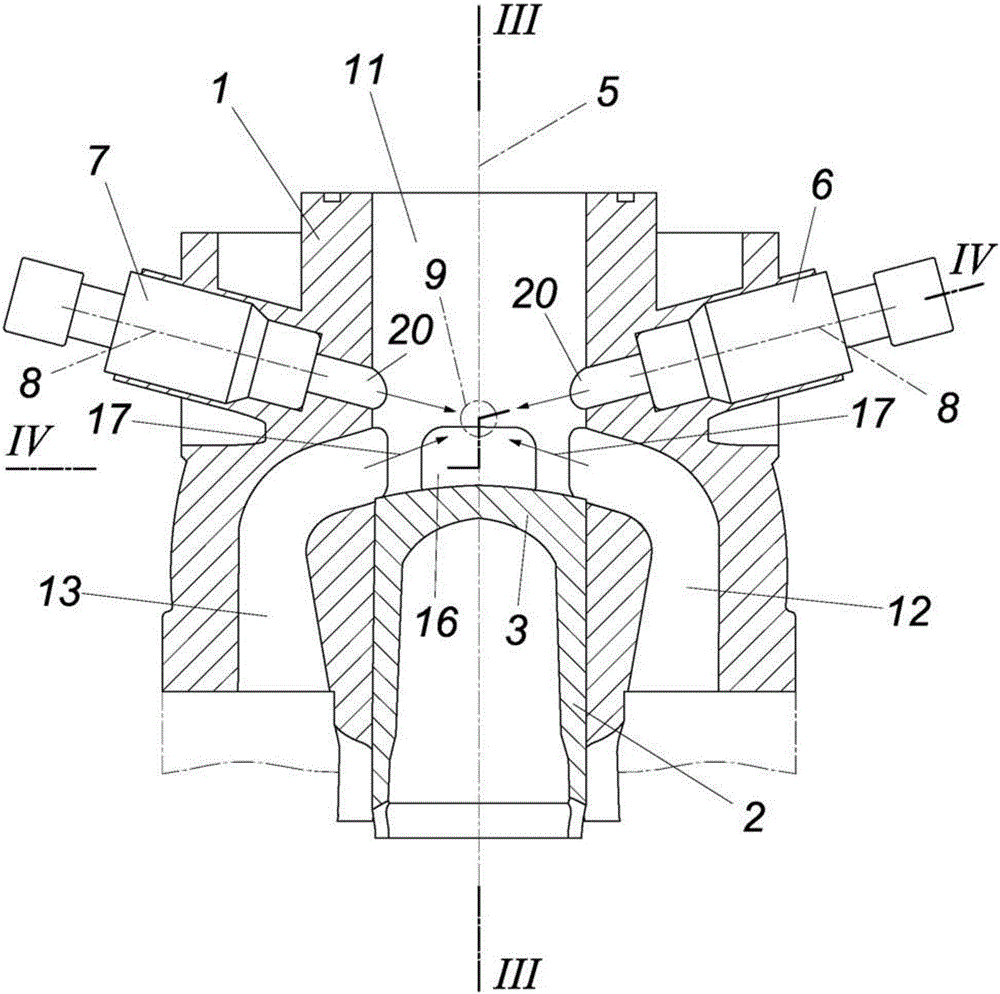

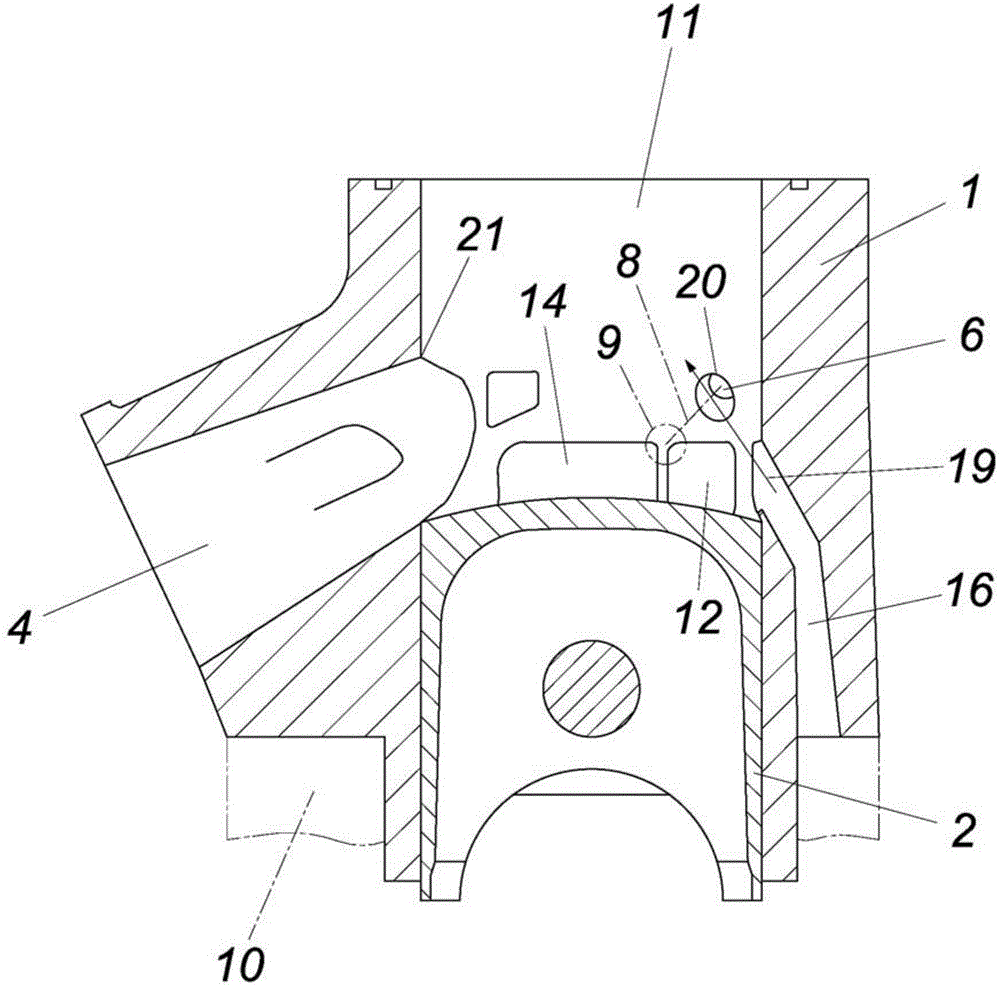

[0016] Only one cylinder 1 of the engine block of the two-stroke Otto engine is shown in the drawing without a cylinder head. The piston shown in the bottom dead center position is marked 2 and has a piston crown 3 . On the side of the cylinder opposite the exhaust duct 4 there are two injection nozzles 6, 7 symmetrical with respect to the diametric plane 5 defined by the axis of the exhaust duct 4, whose nozzle axes 8 intersect in the diametric plane 5, i.e. intersect at the intersection point 9, which is located above the piston crown 3 in the bottom dead center position of the piston 2 shown, as in particular from figure 2 It can be seen in.

[0017] Between the crankcase 10 and the combustion chamber 11 of the cylinder 1 indicated only by dashed lines, there are transfer channels 12 , 13 and 14 , 15 arranged opposite each other in pairs and arranged symmetrically with respect to the diametrical plane 5 . In addition, the cylinder 1 has a transfer channel diametrically o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com