Rapid forming production method of personalized customization concealed teeth correcting equipment

A technology for invisible aligners and manufacturing methods, which is applied in dentistry, orthodontics, orthodontics, etc., can solve the problems of easy oral inflammation and low biocompatibility, and achieve inhibition of bacterial growth, high surface roughness, Anti-inflammation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific implementation examples

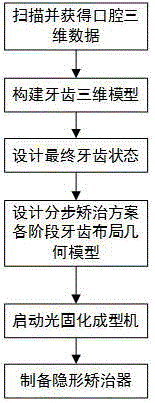

[0026] Below in conjunction with specific implementation example the present invention is described in further detail, please refer to figure 1 .

[0027] The present invention describes a rapid prototyping manufacturing method of personalized customized teeth invisible braces appliance, which specifically includes the following steps:

[0028] Step 1. Use Micro-CT to scan and obtain the three-dimensional data of the patient's oral cavity;

[0029] Step 2. Import the 3D data of the patient's oral cavity scanned in Step 1 into the 3D digital orthodontic software OrthoRx to reconstruct the patient's tooth model. During image processing, the tooth root is separated from the entire tooth tissue image to obtain an independent tooth model, that is, the original tooth state;

[0030] Step 3. In the 3D digital orthodontic software OrthoRx, the teeth to be corrected are arranged neatly, and the final neatly arranged teeth are generated;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com