Battery nickel sheet bending fixture

A nickel sheet and battery technology, which is applied in the field of battery nickel sheet bending fixtures, can solve problems such as reducing the yield rate of battery products, and achieve the effects of simple structure, improved yield rate, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Preferred embodiments of the present invention will be described in detail below with reference to the drawings.

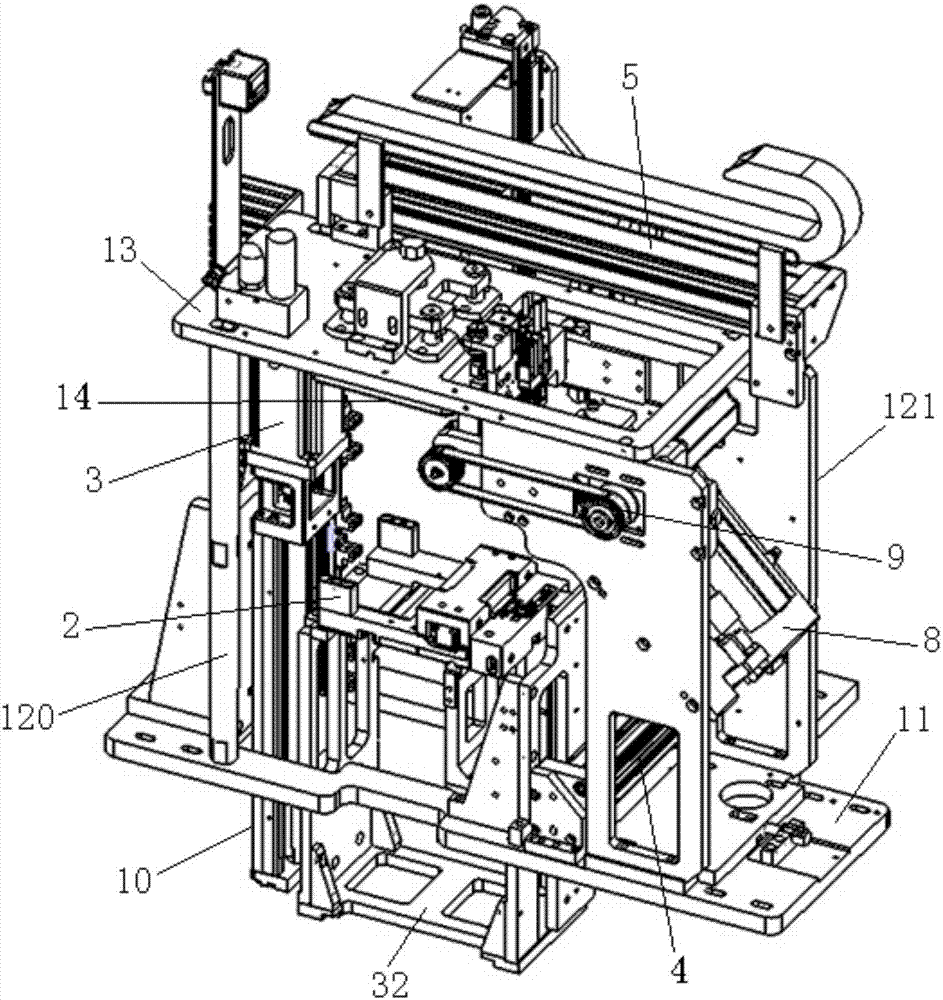

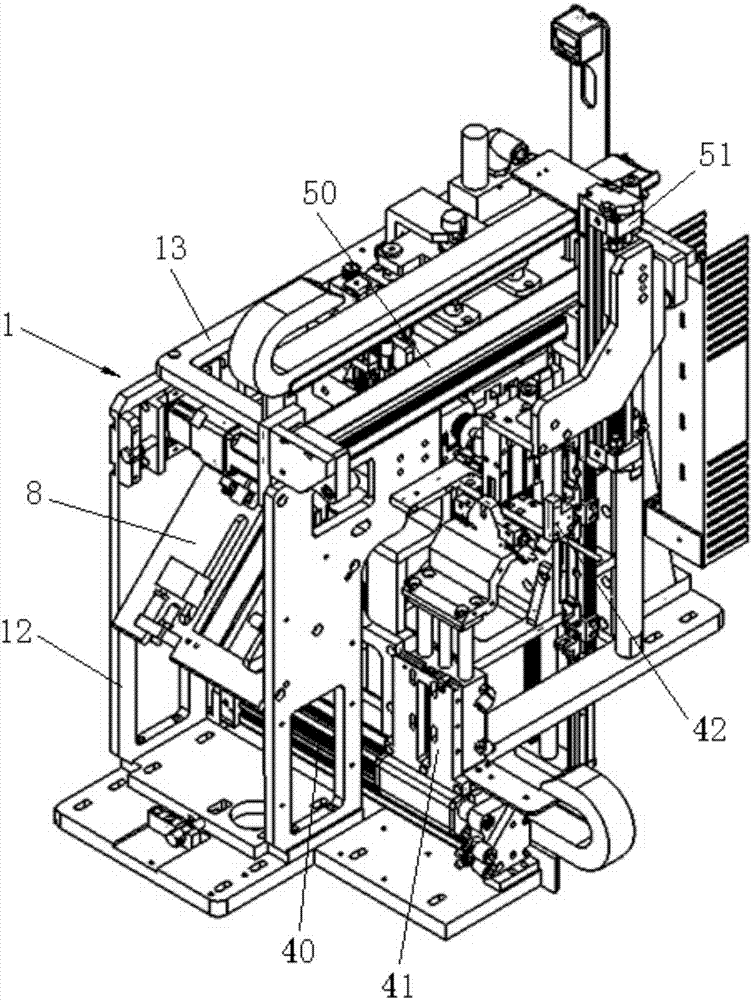

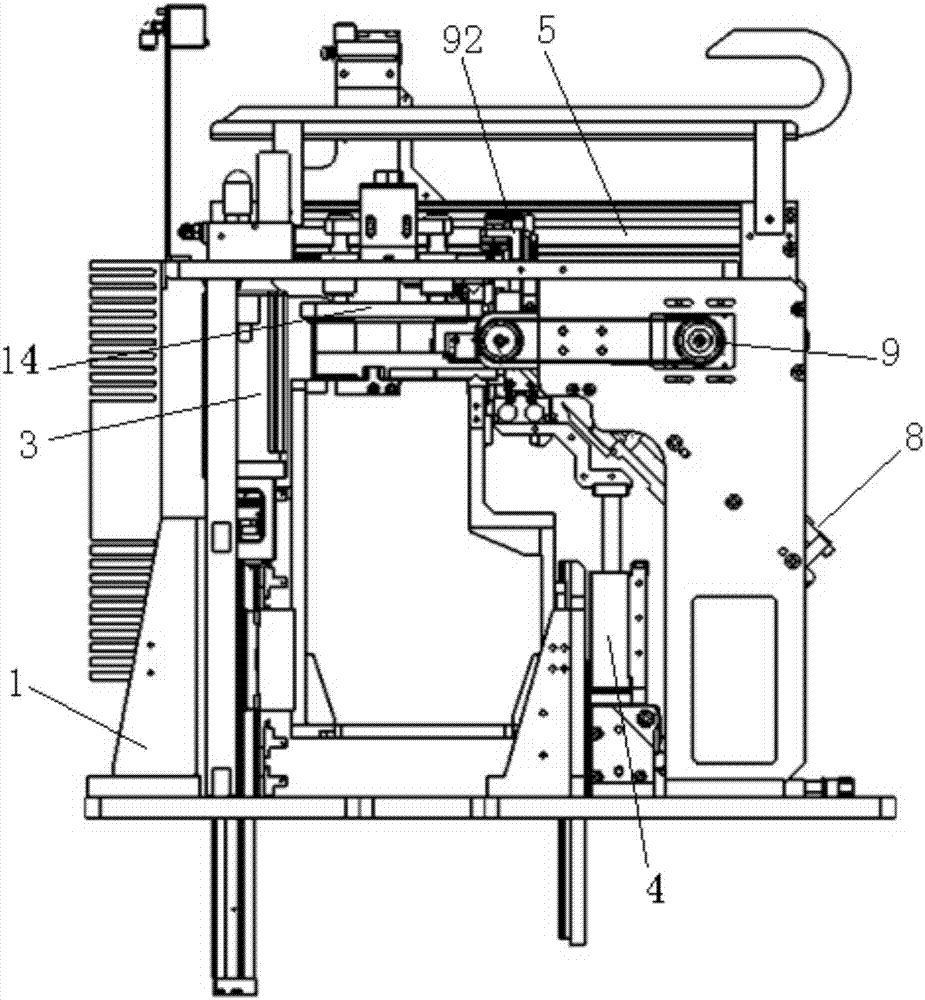

[0056] The invention discloses a battery nickel sheet bending jig, comprising a frame 1, a carrier 2, and a lifting drive mechanism 3 respectively connected to the frame 1, a carrier removal mechanism 4, and a carrier return mechanism 5 . The bending blade 6 and the first jaw cylinder 7 made of insulating material, wherein, the frame 1 is provided with a feeding station and a bending station, and the bending station is arranged on the upper The top of the material station; the carrier 2 includes a battery carrying portion 20 for receiving batteries, and a nickel sheet carrying portion 21 for receiving nickel sheets, the battery carrying portion 20 and the nickel sheet carrying portion 21 are detachably positioned and connected together, and the battery bearing part 20 is also placed on the lifting drive mechanism 3 together with the nickel sheet bearing par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com