Machining process for herringbone oblique tooth key groove

A processing technology and keyway technology, which is applied in the field of herringbone helical tooth keyway processing technology, can solve the problems of difficult processing, inability to judge, and no specific instructions for the alignment position, and achieve simple operation, high precision, improved reliability and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

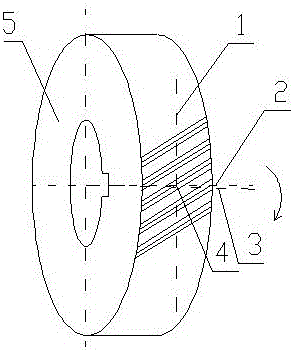

[0012] Herringbone helical gears are often used in lifting gearboxes. The production process is generally divided into steps such as welding gears, stress relief and tempering, ultrasonic inspection, rough turning, gear hobbing, scribing and centering, keyway milling, and magnetic particle inspection. Keyway milling steps, due to the particularity of herringbone helical teeth, the keyway baseline is difficult to determine, such as figure 1 As shown, the present invention discloses a herringbone helical tooth keyway processing technology, including the following steps:

[0013] (5) Find gear centerline 2: Use the step side near the gear shaft as the positioning reference surface 5. Use a probe on the machining center to find the intersection 4 of the tooth slot center line 1 and the tooth width center line, and use the intersection Point 4 determines the gear centerline 2;

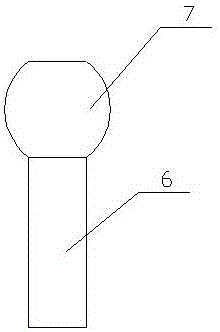

[0014] (1) Retest: such as figure 2 As shown, the centering tool includes a clamping handle 6 and a detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com