Novel poly N-isopropylacrylamide hydrogel, and preparation method and application thereof

A technology of isopropylacrylamide and methacryloyl chloride, applied in the field of smart hydrogels, can solve the problems of poor mechanical properties of PNIPAAm hydrogels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

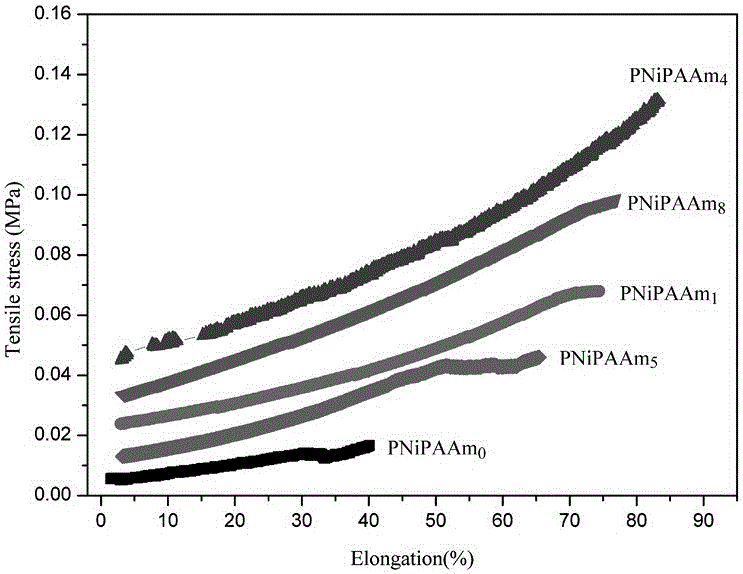

Problems solved by technology

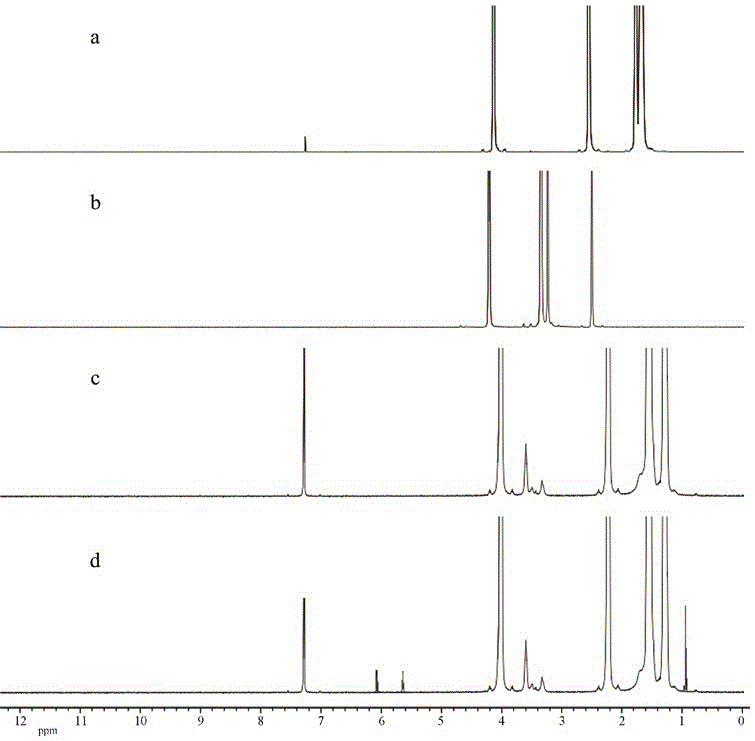

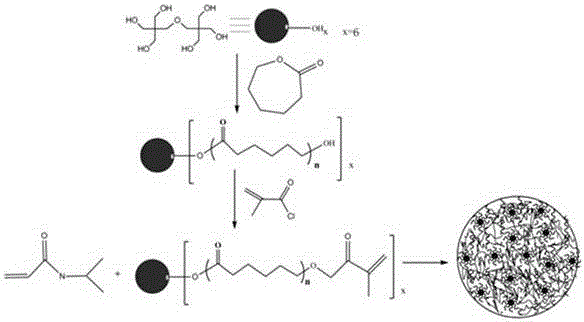

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of dipentaerythritol polycaprolactate (DPCL)

[0035] Add 0.254g dipentaerythritol (DPE, 1mmol), 0.685g 6-caprolactone ( ε - CL, 60 mmol), under the protection of nitrogen, it was melted and mixed uniformly at 120 °C, and then 0.1 wt% stannous octoate was added dropwise as a catalyst, and reacted at 120 °C for 6 h under the protection of nitrogen. After the reaction is completed, cool to room temperature, dissolve with dichloromethane, then add dropwise to ice-cold n-hexane / methanol to precipitate, filter, dry, and vacuum dry;

[0036] (2) Preparation of methacrylic acid-terminated dipentaerythritol polycaprolactate (DPCLMAC)

[0037] Dissolve 0.65g (1 mmol) of DPCL in 40g of dichloromethane, add 0.55g (54 mmol) of triethylamine, stir to dissolve completely, add dropwise 0.38g of methacryloyl chloride (MAC, 36 mmol ) and 20g of dichloromethane, the dropwise addition time is controlled at 2-3h, after the dropwise addition is completed, the temperature ...

Embodiment 2

[0041] (1) Preparation of dipentaerythritol polycaprolactate (DPCL)

[0042] Add 0.254g dipentaerythritol (DPE, 1mmol), 0.685g 6-caprolactone ( ε - CL, 60 mmol), under the protection of nitrogen, it was melted and mixed uniformly at 120 °C, and then 0.1 wt% stannous octoate was added dropwise as a catalyst, and reacted at 120 °C for 6 h under the protection of nitrogen. After the reaction is completed, cool to room temperature, dissolve with dichloromethane, then add dropwise to ice-cold n-hexane / methanol to precipitate, filter, dry, and vacuum dry;

[0043] (2) Preparation of methacrylic acid-terminated dipentaerythritol polycaprolactate (DPCLMAC)

[0044] Dissolve 0.65g (1 mmol) of DPCL in 40g of dichloromethane, add 0.55g (54 mmol) of triethylamine, stir to dissolve completely, add dropwise 0.38g of methacryloyl chloride (MAC, 36 mmol ) and 20g of dichloromethane, the dropwise addition time is controlled at 2-3h, after the dropwise addition is completed, the temperature ...

Embodiment 3

[0048] (1) Preparation of dipentaerythritol polycaprolactate (DPCL)

[0049] Add 0.254g dipentaerythritol (DPE, 1mmol), 0.685g 6-caprolactone ( ε - CL, 60 mmol), under the protection of nitrogen, it was melted and mixed uniformly at 120 °C, and then 0.1 wt% stannous octoate was added dropwise as a catalyst, and reacted at 120 °C for 6 h under the protection of nitrogen. After the reaction is completed, cool to room temperature, dissolve with dichloromethane, then add dropwise to ice-cold n-hexane / methanol to precipitate, filter, dry, and vacuum dry;

[0050] (2) Preparation of methacrylic acid-terminated dipentaerythritol polycaprolactate (DPCLMAC)

[0051] Dissolve 0.65g (1 mmol) of DPCL in 40g of dichloromethane, add 0.55g (54 mmol) of triethylamine, stir to dissolve completely, add dropwise 0.38g of methacryloyl chloride (MAC, 36 mmol ) and 20g of dichloromethane, the dropwise addition time is controlled at 2-3h, after the dropwise addition is completed, the temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com