Microorganism metallurgical reactor suitable for extremely cold environment

An extremely cold environment and reactor technology, applied in the field of metallurgy, can solve problems such as the influence of climatic conditions on biological oxidation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

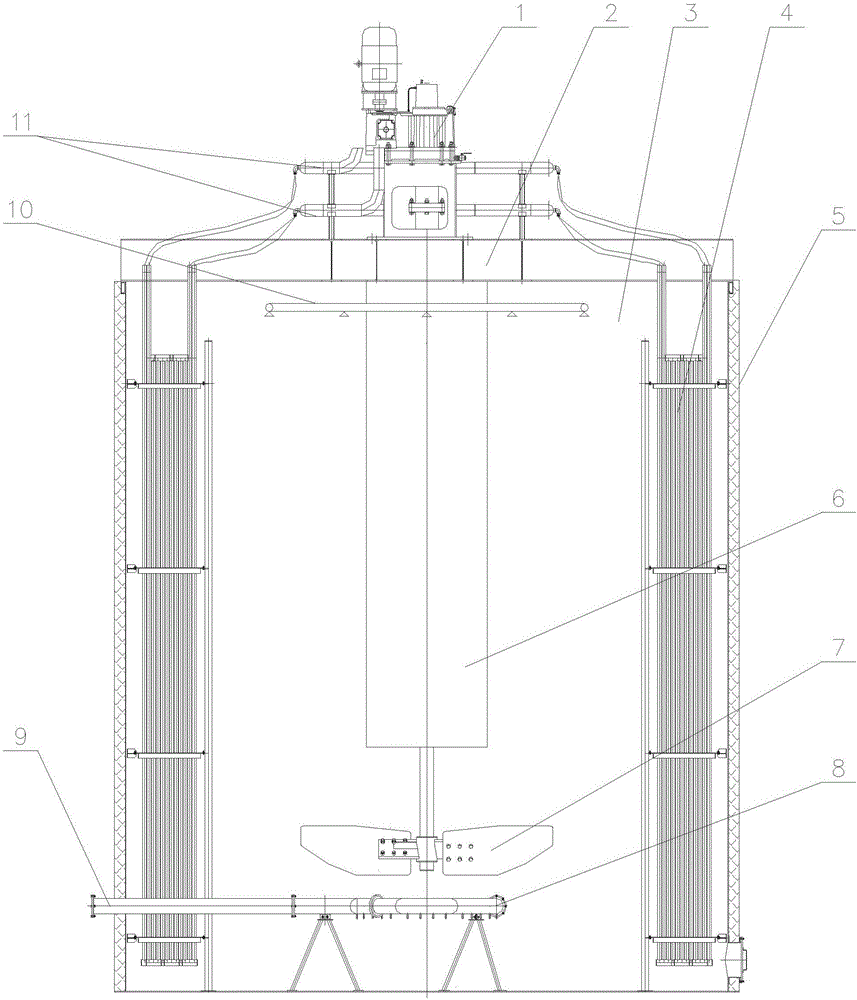

[0011] The technical solutions of the present invention will be further explained and illustrated below in conjunction with the accompanying drawings of the description.

[0012] The reactor mainly includes: drive motor reducer 1, sealed bridge upper cover 2, stainless steel tank body 3, snake tube heat exchanger 4, shell insulation layer 5, feed guide tube 6, agitator 7, punching Pipe aeration ring 8, air intake pipe 9, spray defoaming device 10 and exchange water into and out of distributor 11.

[0013] The drive motor reducer 1 is fixed on the center of the stainless steel tank 3 through the sealed bridge cover 2, the agitator 7 is connected with the drive motor reducer 1, and the feed guide tube 6 is set outside the agitator 7 and fixed on the sealed bridge The bottom of the upper cover 2; the water exchange water inlet and outlet distributor 11 is installed on the upper part of the sealed bridge upper cover 2 and placed around the drive motor reducer 1, and the coil heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com