Formula and technology for producing synthetic leather from graphene modified waterborne polyurethane

A water-based polyurethane and graphene modification technology, which is applied in polyurea/polyurethane coatings, coatings, textiles and papermaking, etc., can solve the problems of affecting the hand feel, insufficient wear fastness of the base, and no air permeability of the water-based foam base. , to achieve the effect of good air permeability, plump, smooth and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

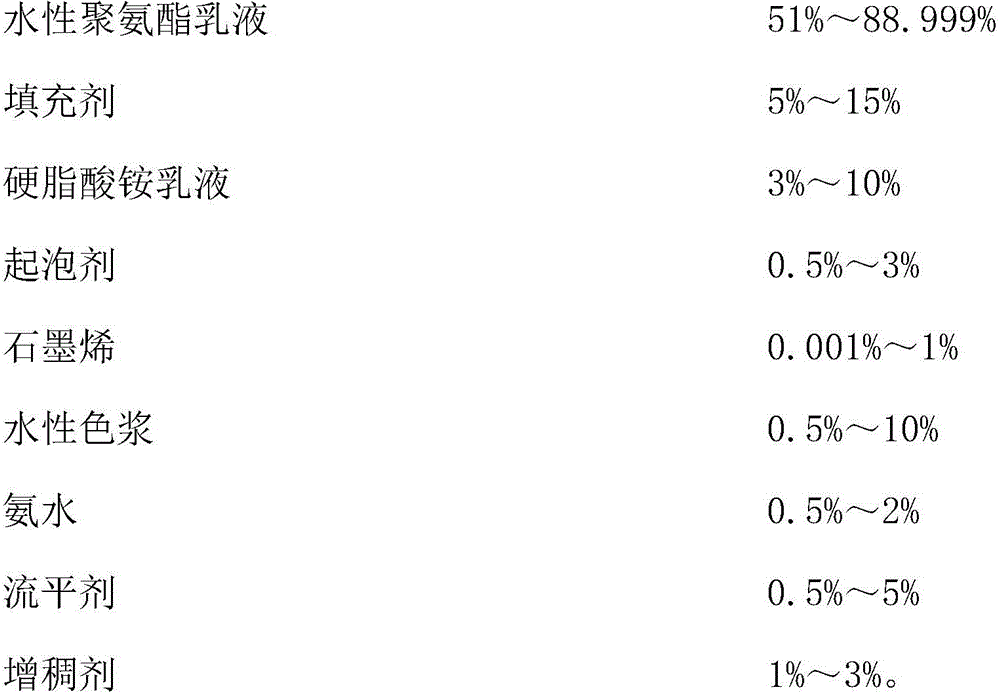

[0032] Prepare the coating solution according to the following ratio:

[0033]

[0034] Add the raw materials except the thickener in the prescribed amount in sequence in the container, stir evenly with a disperser mixer, the stirring speed of the disperser mixer is 1200 rpm, after filtering, add the thickener to adjust the viscosity to obtain a coating liquid.

[0035] The prepared coating solution is made into an 8-fold coating foam through an intelligent dynamic foam generator, and then the coating foam is applied to the leather base cloth. The coating method is knife coating, roller coating or roller coating. The application amount is precisely controlled by the computer, and the application thickness is adjusted according to the requirements of different leather products.

[0036] After the coating is completed, it is dried in an oven, multi-stage temperature control is implemented, and the temperature is raised in stages. The temperature is 50°C to 160°C, and the grap...

Embodiment 2

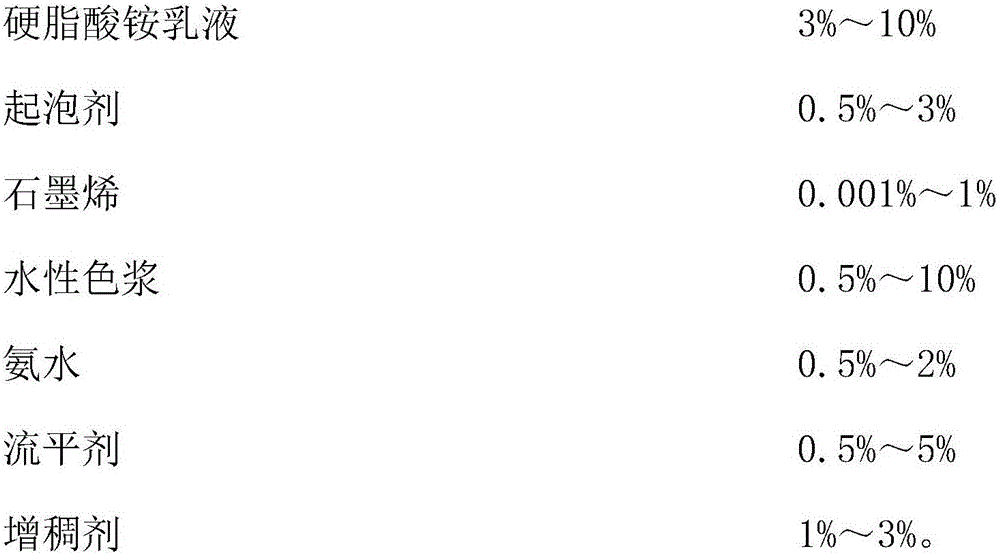

[0039] Prepare the coating solution according to the following ratio:

[0040]

[0041]

[0042] Add the raw materials except the thickener in the prescribed amount in sequence in the container, stir evenly with a disperser mixer, the stirring speed of the disperser mixer is 1500 rpm, after filtering, add the thickener to adjust the viscosity to obtain a coating liquid.

[0043] The prepared coating solution is made into a 10-fold coating foam through an intelligent dynamic foam generator, and then the coating foam is applied to the leather base cloth. The coating method is knife coating, roller coating or roller coating. The application amount is precisely controlled by the computer, and the application thickness is adjusted according to the requirements of different leather products.

[0044] After the coating is completed, it is dried in an oven, multi-stage temperature control is implemented, and the temperature is raised in stages at a temperature of 50°C to 180°C t...

Embodiment 3

[0047] Prepare the coating solution according to the following ratio:

[0048]

[0049]

[0050] Add the raw materials except the thickener in the prescribed amount in the container in turn, stir evenly with a disperser mixer, the stirring speed of the disperser mixer is 1800 rpm, after filtering, add the thickener to adjust the viscosity to obtain a coating liquid.

[0051] The prepared coating solution is made into a 15-fold coating foam through an intelligent dynamic foam generator, and then the coating foam is applied to the leather base cloth. The coating method is knife coating, roller coating or roller coating. The application amount is precisely controlled by the computer, and the application thickness is adjusted according to the requirements of different leather products.

[0052] After the coating is completed, it is dried in an oven, multi-stage temperature control is implemented, and the temperature is raised in stages at a temperature of 50 ° C to 200 ° C t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com