Cold-resistant wear-resistant synthetic leather, preparation method and equipment

A synthetic leather, cold-resistant technology, applied in the directions of mixing methods, chemical instruments and methods, mixers, etc., can solve the problems of affecting style and appearance, poor moisture permeability and air permeability, and the effect is not obvious, and achieve moisture permeability and air permeability. Good performance, soft feel, plump, smooth and soft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

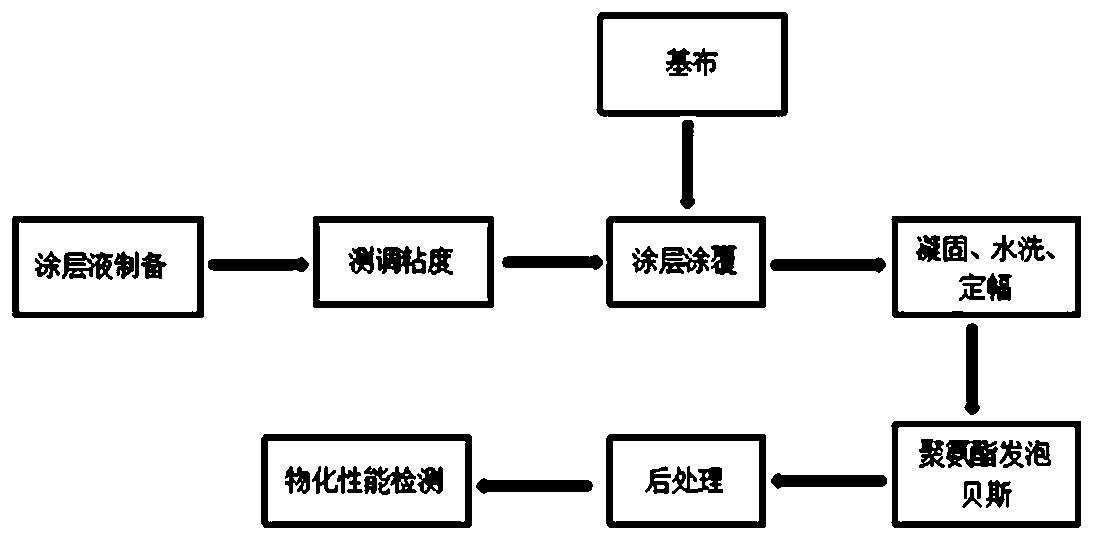

[0035] Embodiment one: see figure 1 , a cold-resistant and wear-resistant synthetic leather provided by the present invention, including a coating liquid, which is prepared from the following components in parts by weight: 60% water-based polyurethane, 13% light calcium, and 3%- 10%, foam stabilizer 7%, graphene 1%, water-based color paste 0.5%-10%, leveling agent 0.5%-10%, thickener 1%-2%, cold resistance agent 1%-3%.

[0036] In this embodiment, the specific component ratio of a kind of cold-resistant wear-resistant synthetic leather is:

[0037] 60% water-based polyurethane, 13% light calcium, 3% foaming agent, 7% foam stabilizer, 1% graphene, 0.5% water-based color paste, 0.5% leveling agent, 1% thickener, and 1% cold-resistant agent.

[0038] A method for preparing the aforementioned cold-resistant and wear-resistant synthetic leather, comprising the following steps:

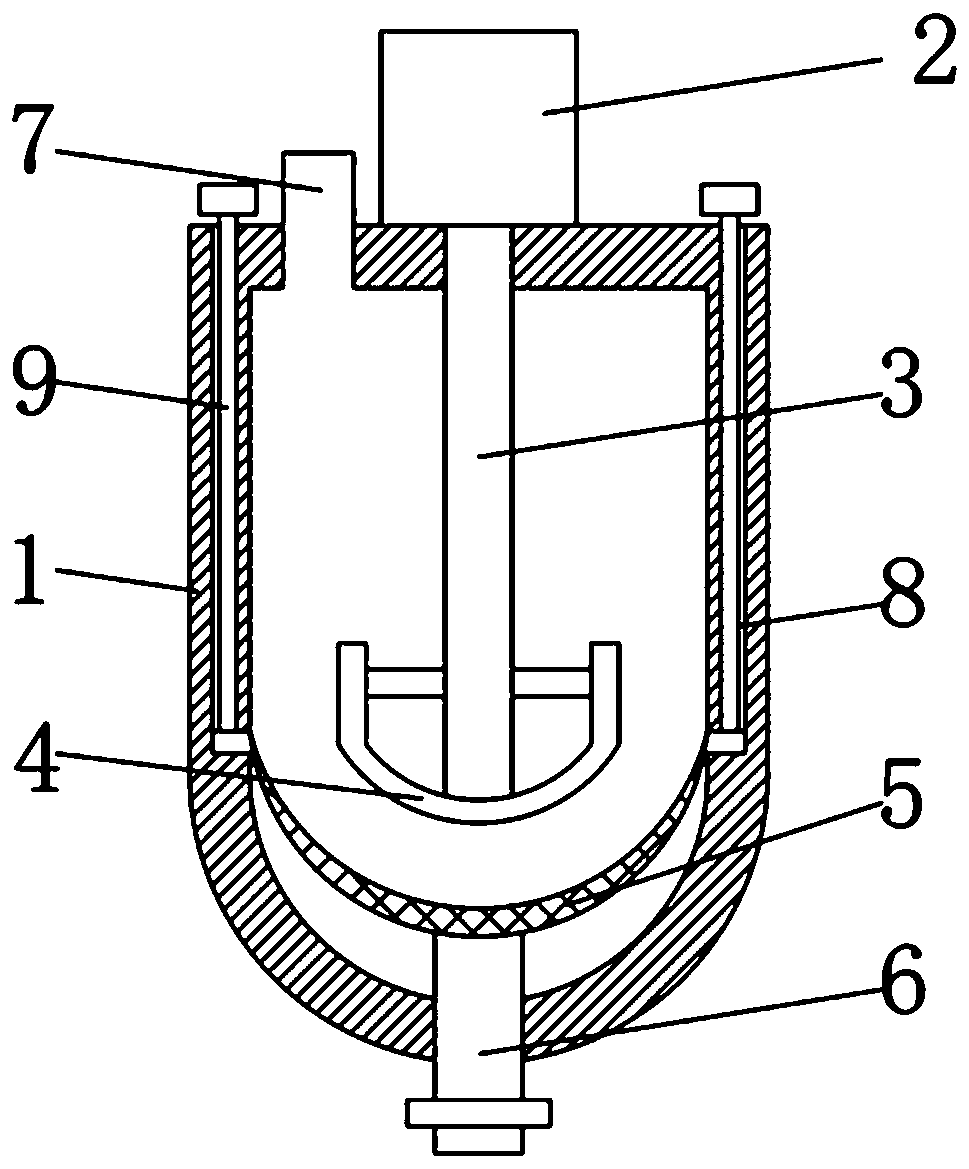

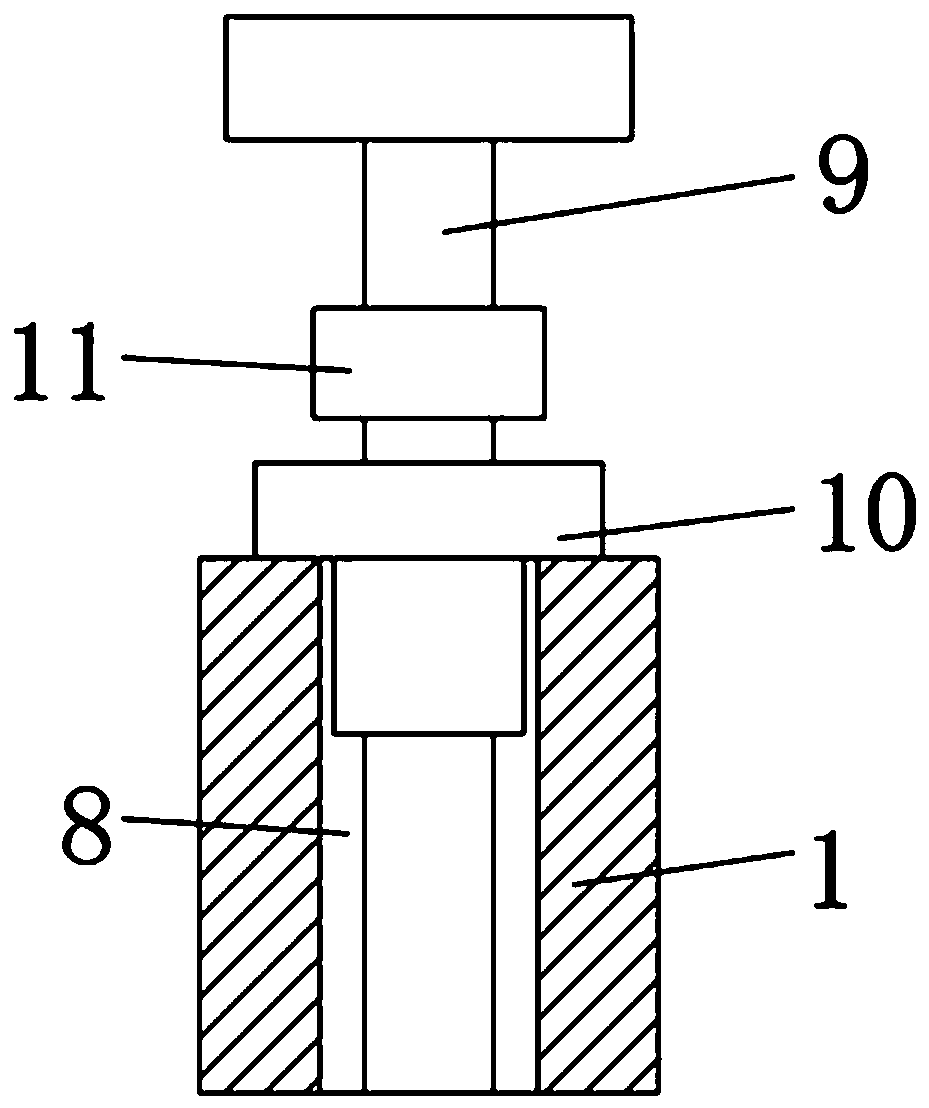

[0039] S1: Preparation of coating liquid: add the above raw materials into the mixing container accord...

Embodiment 2

[0052] See figure 1 , a kind of cold-resistant wear-resistant synthetic leather provided by the present invention, preparation method and preparation equipment, are basically the same as embodiment 1, and its difference is:

[0053] The cold-resistant and wear-resistant synthetic leather is made of specific components in the following proportions by weight:

[0054] Water-based polyurethane 60%, light calcium 13%, foaming agent 6.5%, foam stabilizer 7%, graphene 1%, water-based color paste 5.25%, leveling agent 5.25%, thickener 1.5%, cold resistance agent 2%.

Embodiment 3

[0056] See figure 1 , a kind of cold-resistant wear-resistant synthetic leather provided by the present invention, preparation method and preparation equipment, all basically identical with embodiment 1, 2, its difference is:

[0057] The cold-resistant and wear-resistant synthetic leather is made of specific components in the following proportions by weight:

[0058] Water-based polyurethane 60%, light calcium 13%, foaming agent 10%, foam stabilizer 7%, graphene 1%, water-based color paste 10%, leveling agent 10%, thickener 2%, cold resistance agent 3%.

[0059] The invention provides a cold-resistant and wear-resistant synthetic leather, a preparation method and equipment, which make the synthetic leather have very good air permeability, feel more plump, smooth and soft, endow the synthetic leather with special effects of antistatic, flame retardant and waterproof, and have It has good moisture permeability and air permeability, soft hand feeling, and has a style and appear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com