Composite foundation load detection method

A detection method and composite foundation technology, applied in the field of foundation soil survey, foundation structure engineering, foundation structure test, etc., can solve the problems of low reference value, low data accuracy, long construction period, etc., to shorten the construction period, High reference value, effect of improving foundation bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The scope of application of the present invention: it is applicable to the construction of the stirring pile foundation of sea mud and land soft soil where the depth of the stirring pile of the seawall is less than 20m, and the construction of the two-way cement stirring pile is feasible and has wide applicability.

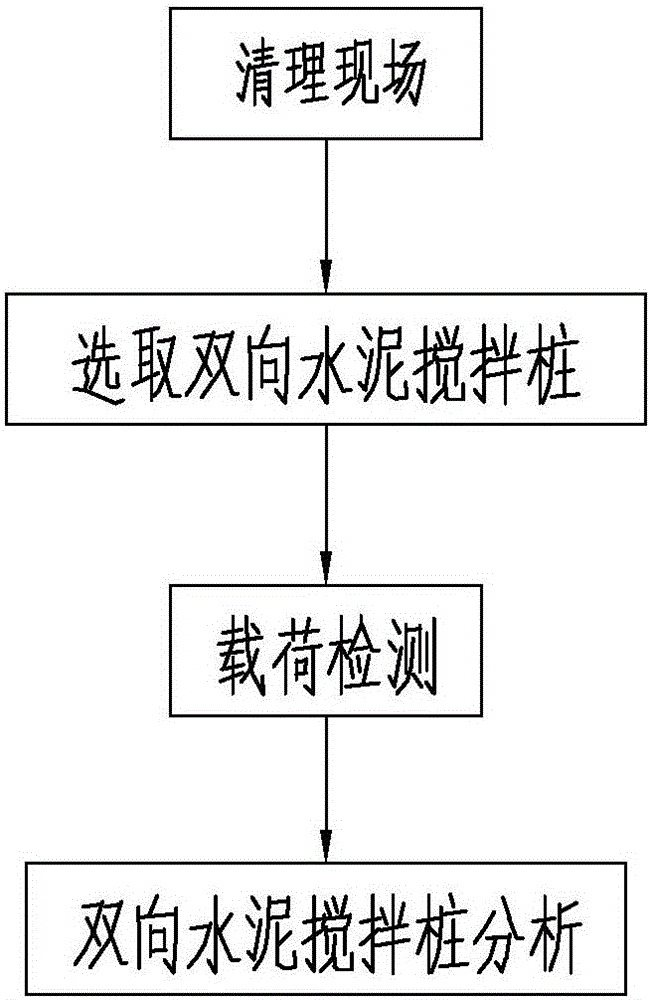

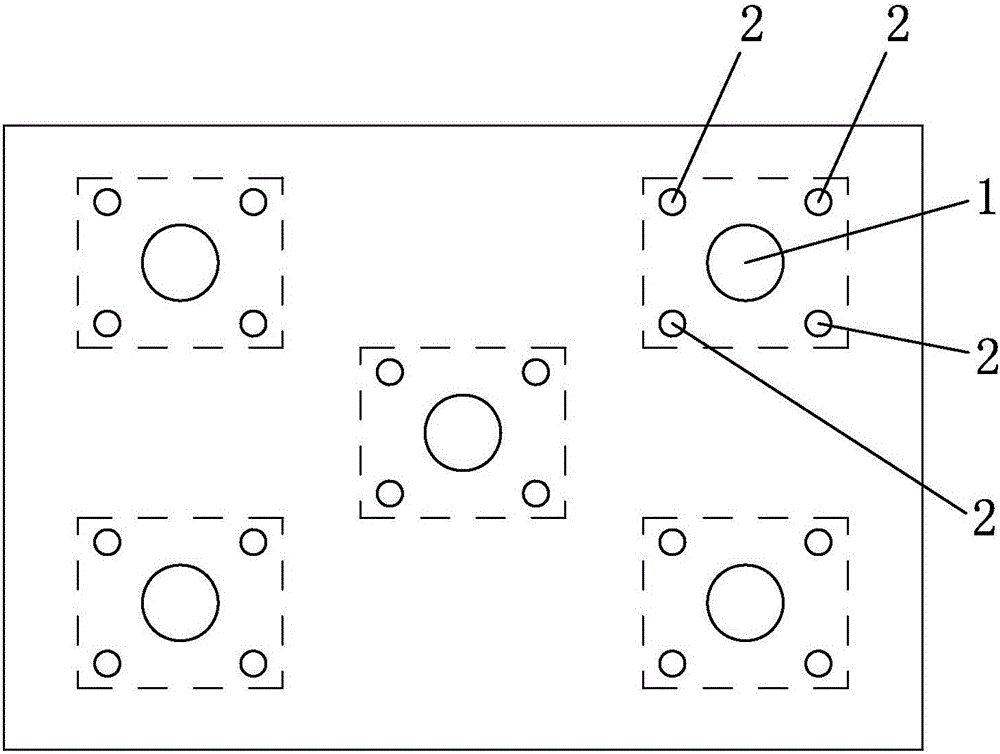

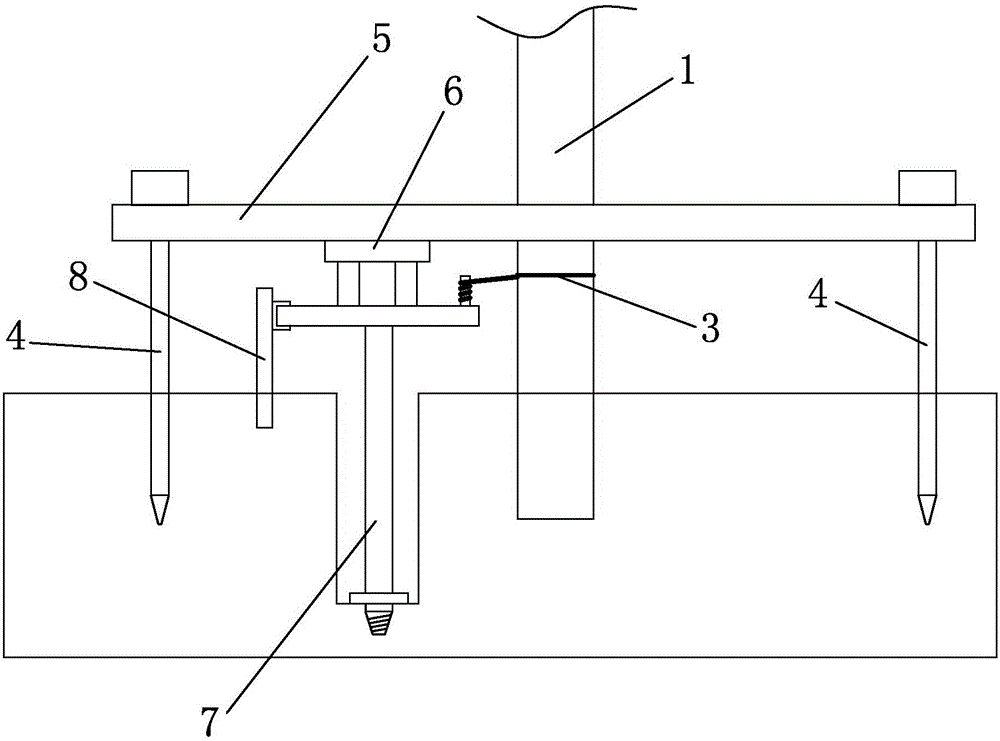

[0027] like Figure 1 to Figure 3 As shown, a composite foundation load detection method includes the following steps:

[0028] (a) Clean up the site: collect the construction waste around the two-way cement mixing pile 1, and pile up the collected construction waste according to three categories: gravel waste, recyclable waste, and hazardous waste. Then, the construction waste shall be arranged and supervised by the person in charge of the construction site. The gravel waste piled up around each two-way cement mixing pile 1 is transported by truck to the designated place for processing; the recyclable waste piled up around each two-way cement mixing pile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

| bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com