Assembly type soft steel damper optimized through equal-stress line

A mild steel damper, isostress technology, applied in building components, anti-vibration and other directions, can solve the problems of low-cycle fatigue performance of dampers, out-of-plane buckling of energy-consuming panels, and large cumulative plastic deformation, and achieve flexible strength and stiffness. , The effect of reducing seismic response and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

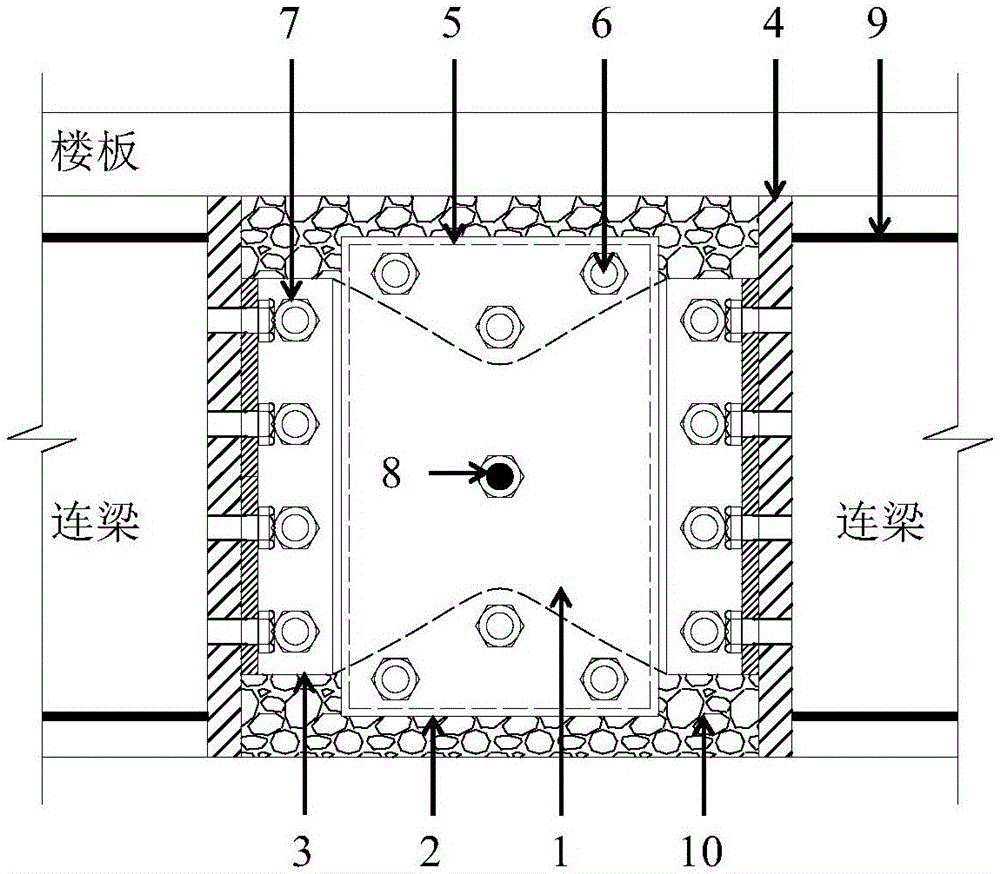

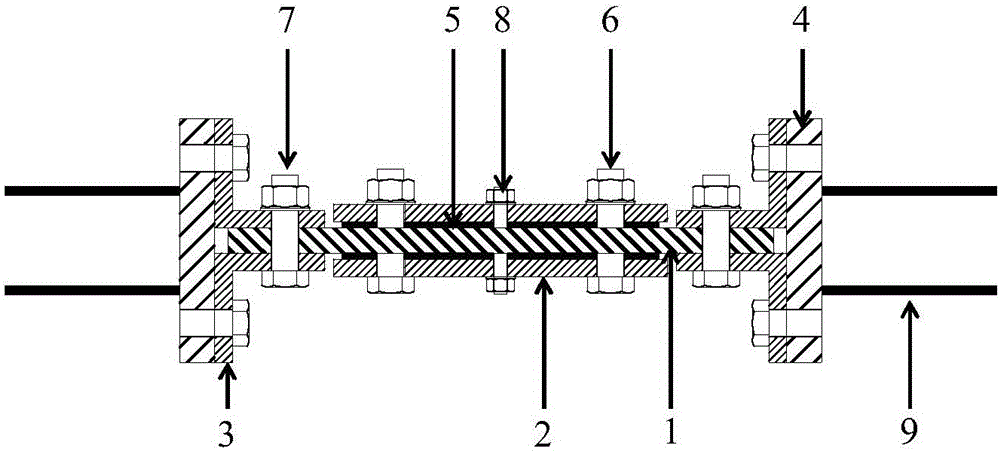

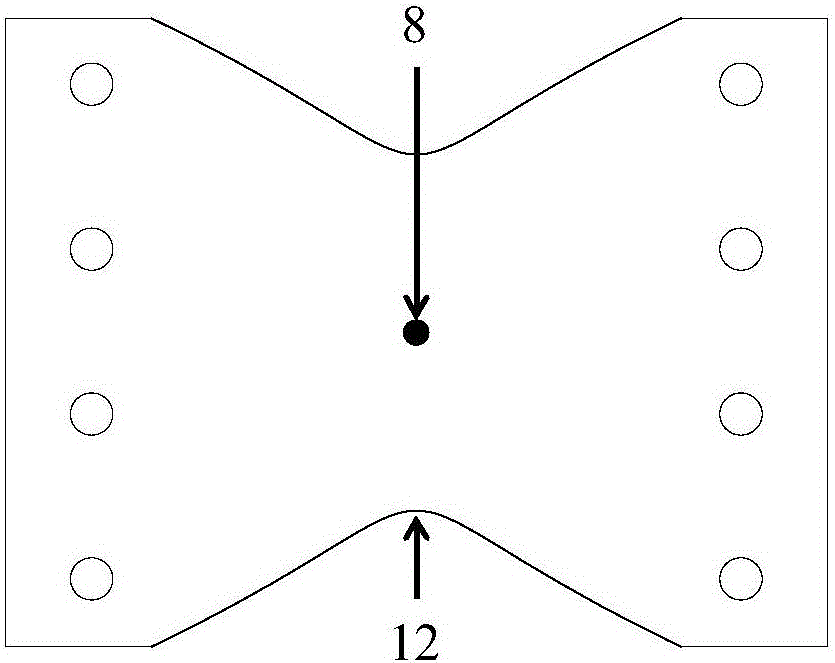

[0023] figure 1 It is a schematic diagram of the structure of this embodiment. This embodiment is composed of mild steel energy dissipation sheet 1, anti-buckling splint 2, L-shaped connecting splint 3, anchoring steel plate 4, polytetrafluoroethylene plate 5, preloaded fastening bolt 6, friction type high-strength connecting bolt 7, limit Bolts 8, pre-embedded anchoring steel bars 9, and flexible filling materials 10. When assembling, the mild steel energy-dissipating sheet 1, 2 PTFE plates 5, and 2 anti-buckling splints 2 are positioned and assembled according to the position of the bolt holes, and fixed with the limit bolt 8 and the preloaded fastening bolt 6. The assembly sequence from the inside to the outside is the mild steel energy dissipation sheet 1, the polytetrafluoroethylene plate 5 and the anti-buckling splint 2, and the two sides are the same. The two ends of the mild steel energy dissipation sheet 1 are connected to the L-shaped connecting splint 3 with frict...

Embodiment 2

[0030] Figure 7 It is a structural sectional view of the present embodiment. Two mild steel energy dissipation sheets 1 are connected in parallel, each mild steel energy dissipation sheet 1 is sandwiched between two polytetrafluoroethylene plates 5, and two anti-buckling splints 2 are arranged on the outermost side. At the position of the L-shaped connecting splint, in order to avoid the gap between the two mild steel energy dissipation sheets, a splint gasket 11 should be filled, the thickness of which is the same as the thickness of the polytetrafluoroethylene plate 5 between the two mild steel energy dissipation sheets 1 same. Other structures are the same as in Embodiment 1.

Embodiment 3

[0032] Figure 8 It is a schematic diagram of the structure of this embodiment. Place the damper at the position between floors, and use the displacement between the upper and lower floors to push the damper to deform and dissipate energy. The upper end of the damper is connected to the upper frame beam, and the lower end is connected to the concrete connecting pier, which is a structural part, with sufficient strength and stiffness to avoid failure before the damper yields. Dampers can be placed in parallel on connecting buttresses. Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com