Hydraulic walking pushing system pump stations

A walking and pushing technology, applied in fluid pressure actuation system components, erecting/assembling bridges, fluid pressure actuation devices, etc., can solve the problems of synchronous precision control being easily affected, multiple operators, etc., and achieve construction saving Bridge costs, strong scalability, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

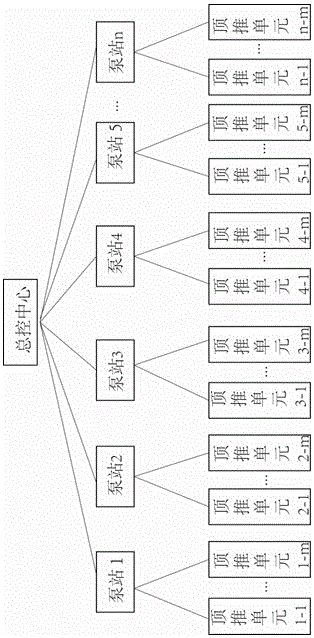

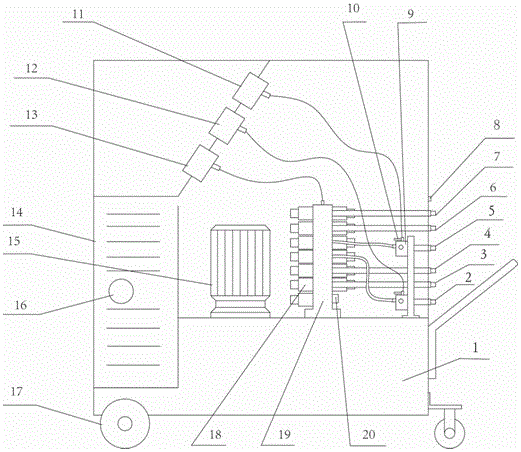

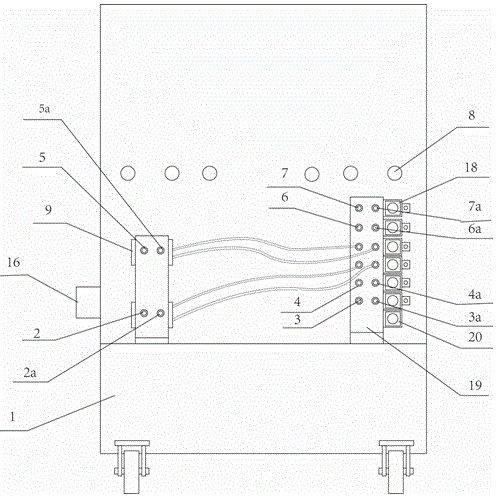

[0037] Such as figure 1 The pumping station of a walking jacking system shown includes a pumping station and a general control center. Each pumping station is equipped with a pumping unit including a fuel tank, an integrated valve group, and an oil inlet and outlet. The general control center have:

[0038] (1) Standard setting unit for jacking, pushing, and rectifying displacements, used to input the standard setting values of displacements for jacking, pushing, and rectifying;

[0039] (2) The real-time displacement data of jacking, pushing, and correction is input to the receiving unit, which is used to receive the real-time displacement data of jacking, pushing, and correction operations;

[0040] (3) Jacking, pushing, and correcting control unit, used to compare the received real displacement data during jacking, pushing, and correcting operations with the displacement standard setting values of jacking, pushing, and correcting , if the real-time displacement data d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com