Heliostat of double-push-rod structure

A heliostat and push rod technology, applied in the field of heliostat, can solve the problems of low cost, large gear ratio and bearing capacity, etc., and achieve the effects of low cost, easy installation and adjustment, and good adaptability to precision requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

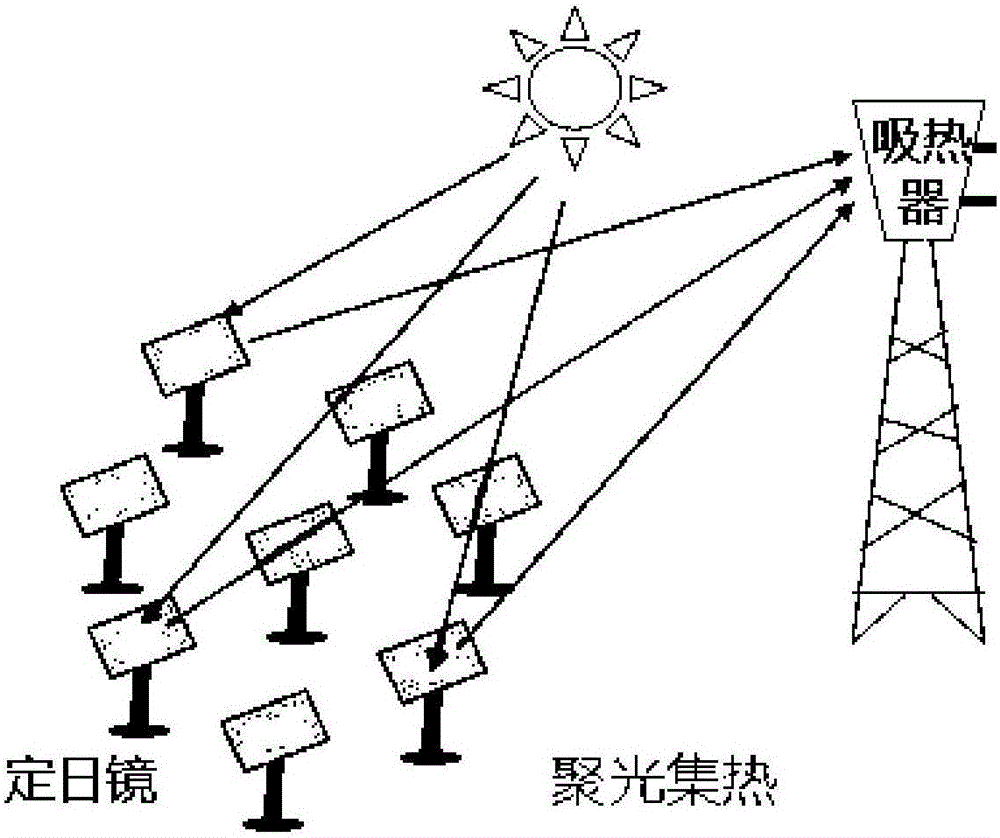

[0040] Such as figure 1 As shown, the tower-type solar thermal power generation uses a large number of directional mirrors (heliostats) to gather sunlight to a central heat exchanger (heat absorber) installed on the top of the tower, and drives the turbine to rotate by heating the fluid inside. to generate electricity, wherein the heliostat has the function of concentrating light and heat.

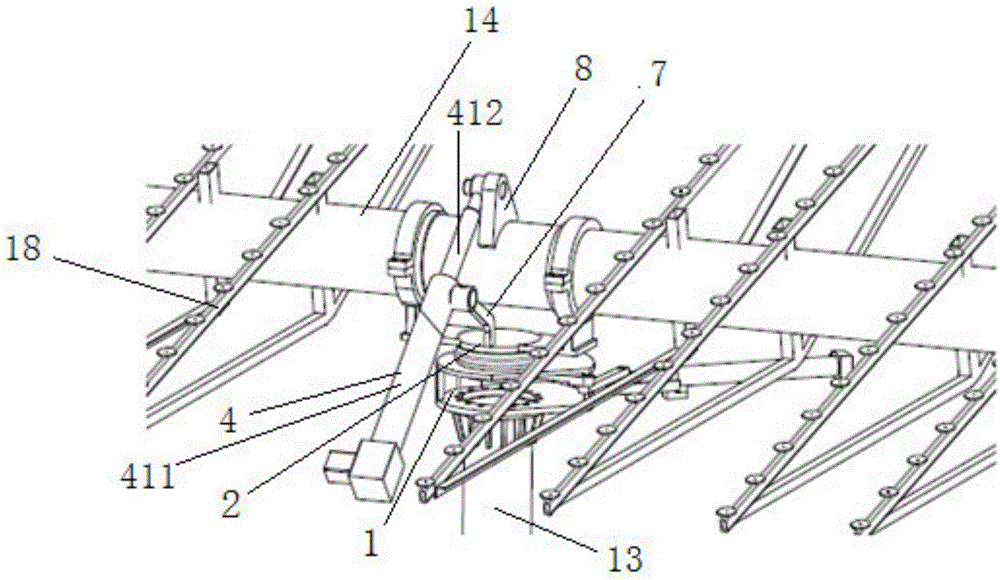

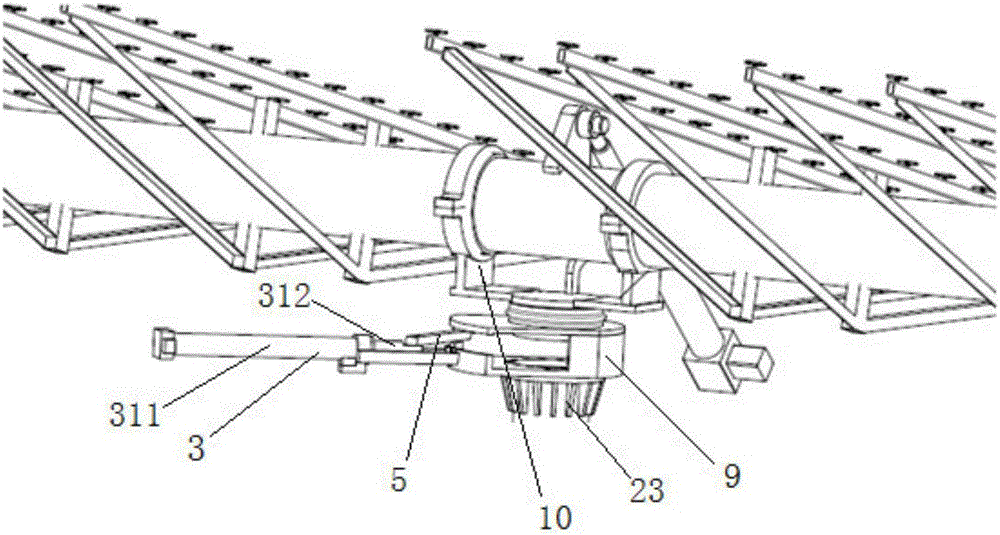

[0041] Such as figure 2 , image 3 , Figure 4 , Figure 5A heliostat with a double push rod structure is shown, and the heliostat includes a reflective surface (not shown in the figure), a mirror frame 18, a main beam 14, a support seat 1, a connecting seat 2, a first bearing ( Not shown in the figure), azimuth telescopic push rod 3, horizontal telescopic push rod 4 and connecting rod 5, the main beam 14 is used to set the mirror frame 18, and the mirror frame 18 is used to support the reflective surface, The main beam 14 is connected to the connecting seat 2 and arranged above the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com