Quartz vessel carburizing device and method used for preparation of high-purity material

A technology for carburizing devices and vessels, which is applied in the field of carburizing devices for quartz vessels made of high-purity materials. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] The present invention will be further described below in conjunction with specific embodiments, but the protection scope of the present invention is not limited thereto.

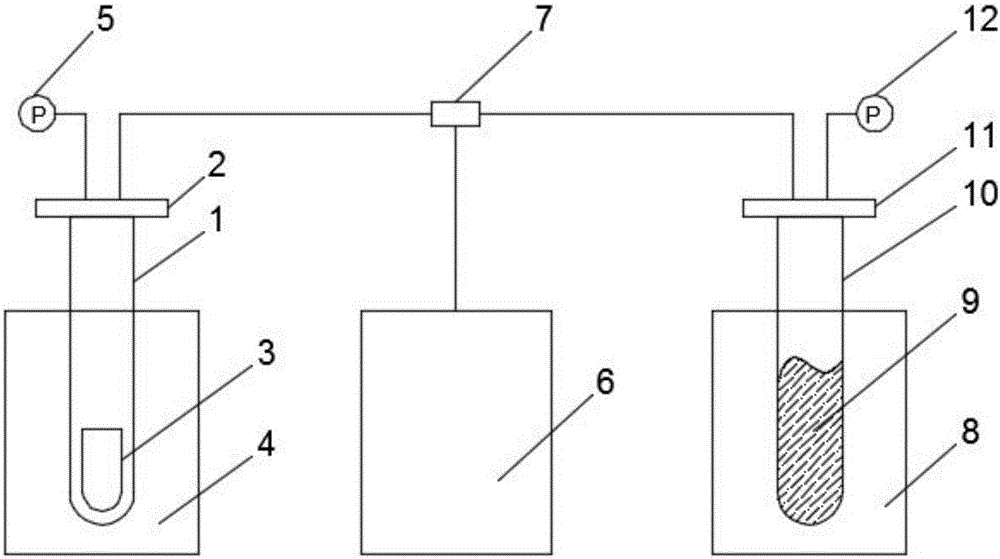

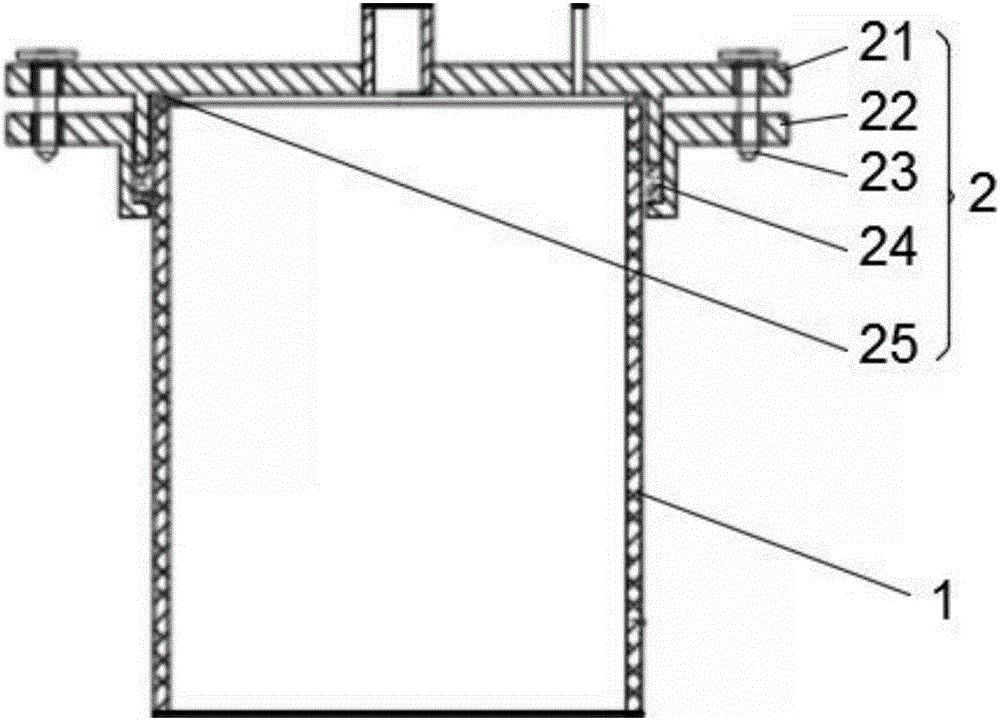

[0018] See figure 1 with figure 2 , The present invention provides a technical solution for a quartz ware carburizing device for the preparation of high-purity materials: a quartz ware carburizing device for the preparation of high-purity materials, comprising a first high-purity quartz tube 1 and a second high-purity quartz tube The quartz tube 10, the first high-purity quartz tube 1 is installed in a high-temperature heating furnace 4, and the first high-purity quartz tube 1 is provided with a carburized quartz vessel 3, and the upper end of the first high-purity quartz tube 1 is installed There is a first sealing device 2, the first sealing device 2 is connected to a first pressure gauge 5 and a three-way valve 7 through a pipeline, the second high-purity quartz tube 10 is installed in a temperature-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap