Method for measuring response time of pyroelectric infrared detector

A pyroelectric infrared, response time technology, applied in the field of infrared detectors, can solve the problems of difficult frequency control, low efficiency, unstable measurement data, etc., to achieve the effect of improving accuracy and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

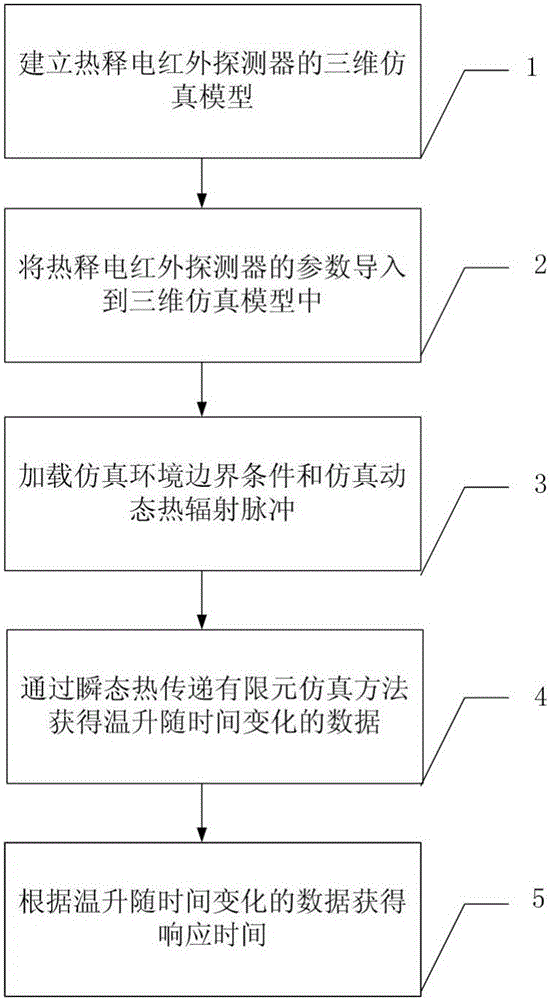

[0023] Embodiment: a kind of method for measuring the response time of pyroelectric infrared detector, its sequential steps are as follows:

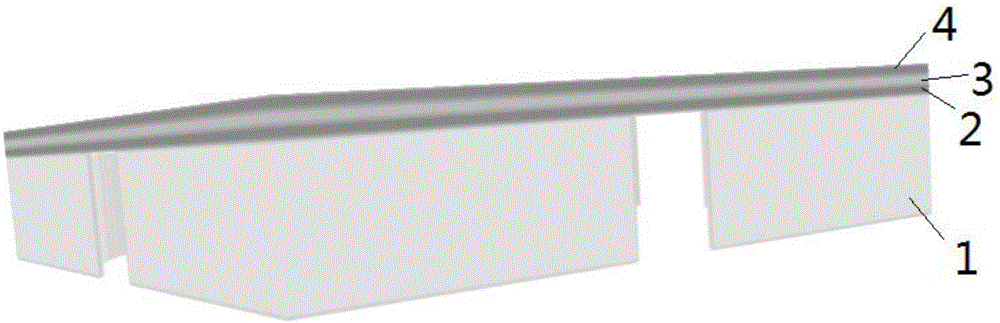

[0024] Step 1: Establish a three-dimensional simulation model of the pyroelectric infrared detector, such as figure 2 As shown, the three-dimensional simulation model includes a bottom supporting layer structure, a bottom metal layer, a sensitive material layer and a top metal absorption layer stacked sequentially from bottom to top;

[0025] Step 2: Import the parameters of the pyroelectric infrared detector to be tested into the three-dimensional simulation model;

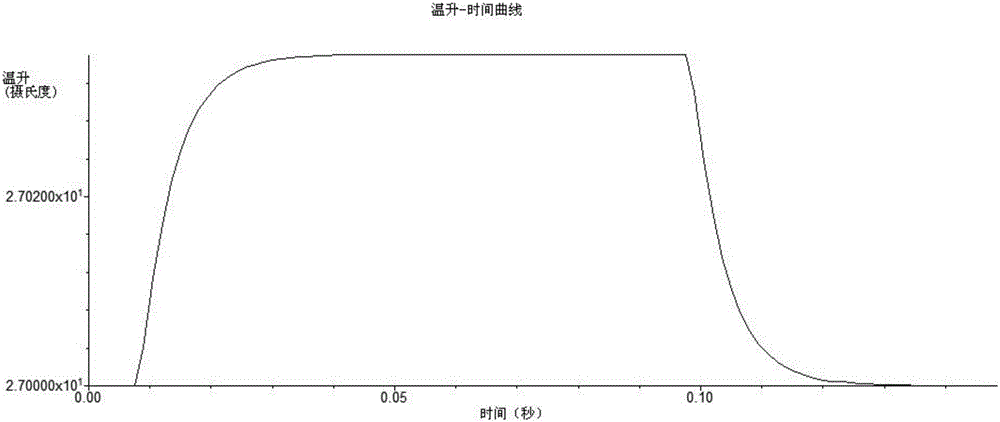

[0026] Step 3: Load the environmental boundary conditions on the 3D simulation model, set the temperature at the bottom of the support structure of the 3D simulation model to 27°C, and after loading the environmental boundary conditions on the 3D simulation model for 10 milliseconds, define the three-dimensional The stable temperature of the simulation model is T 0 , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com