Baking molds for making food

A mold and baking technology, applied in the direction of baked food, special commodity baking, baked hollow food, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

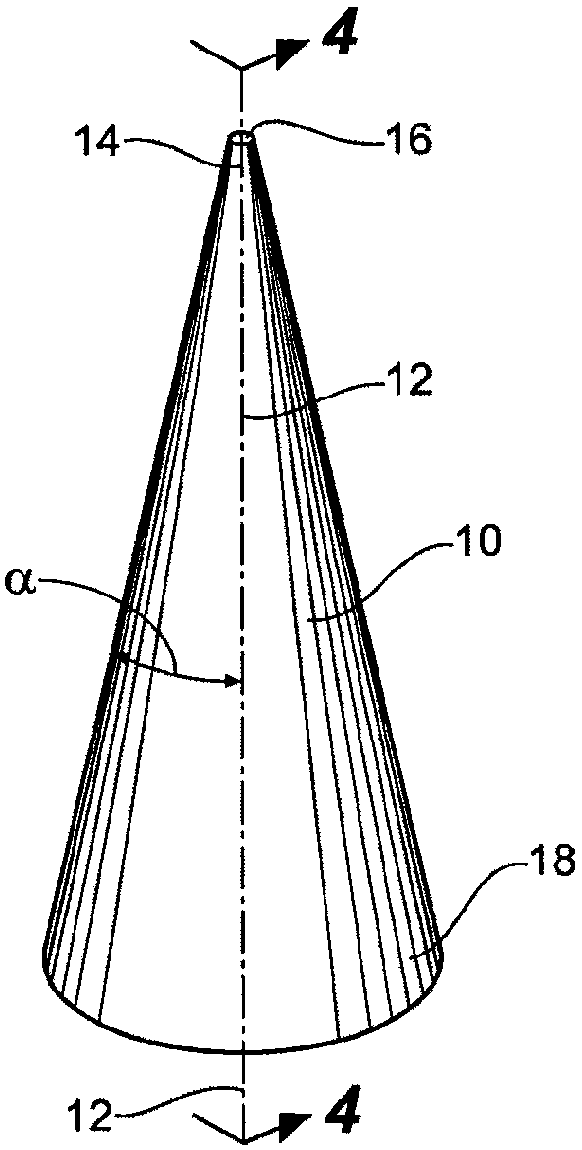

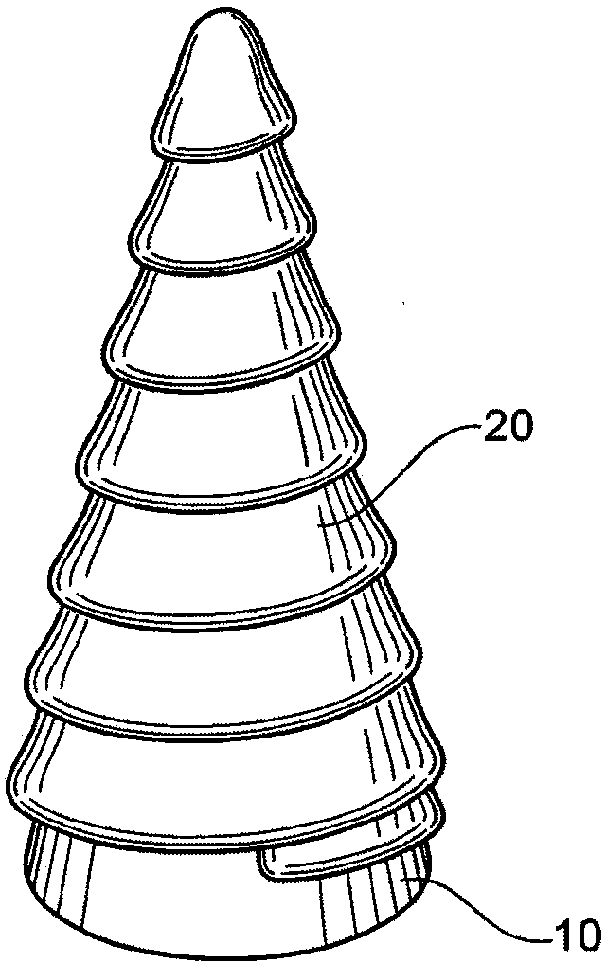

[0048] first reference figure 1 , shows a conical baking mold according to the invention and is referenced 10 . As shown, the baking mold 10 defines an axis 12 and has a top end 14 formed with air holes 16 . Relative to its tip 14 , the base end 18 of the baking mold 10 is dimensioned to establish a taper for the baking mold 10 , defined by the angle α. As contemplated by the present invention, the angle α is approximately 14°. figure 2 The positioning of a food holder 20 made according to the invention on a baking mold 10 is shown, for example. In particular, the food holder 20 is shown after its manufacture (ie after baking) and before it is removed from the baking mold 10 .

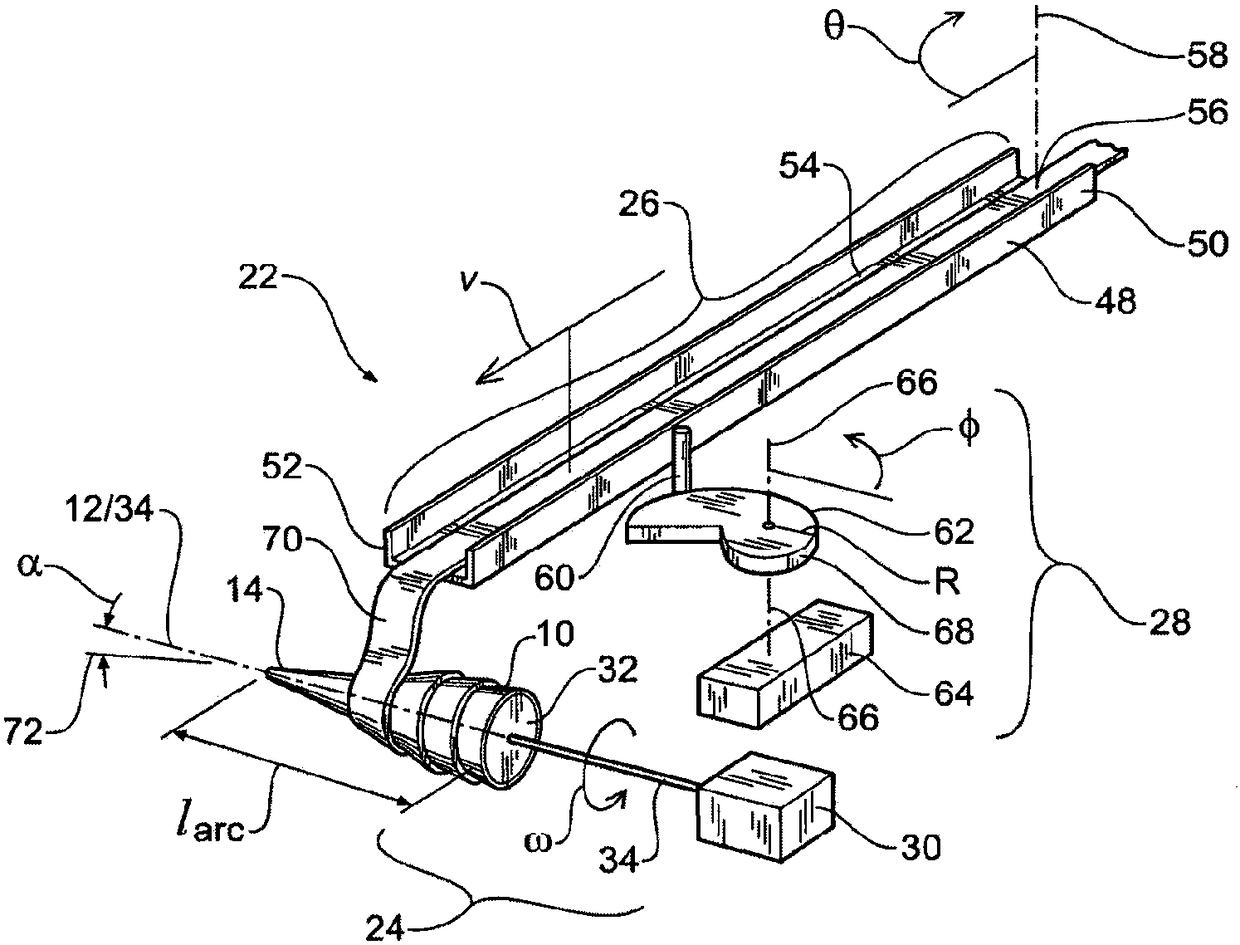

[0049] image 3 A system for manufacturing a food holder 20 according to the invention is shown in and generally designated 22 . As shown, system 22 includes forming unit 24 , transfer unit 26 and control unit 28 . In combination, the units 24 , 26 and 28 cooperate with each other to manufacture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com