Heat treatment method for AHSS hot rolled coils, and cold rolling method using same and heat treatment apparatus

A heat treatment method and heat treatment device technology, applied in heat treatment furnaces, heat treatment equipment, workpiece cooling devices, etc., can solve the problems of inaccessible hot gas and scarce hot gas, achieve smooth circulation, maintain flow rate, and prevent wrinkles and poor shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

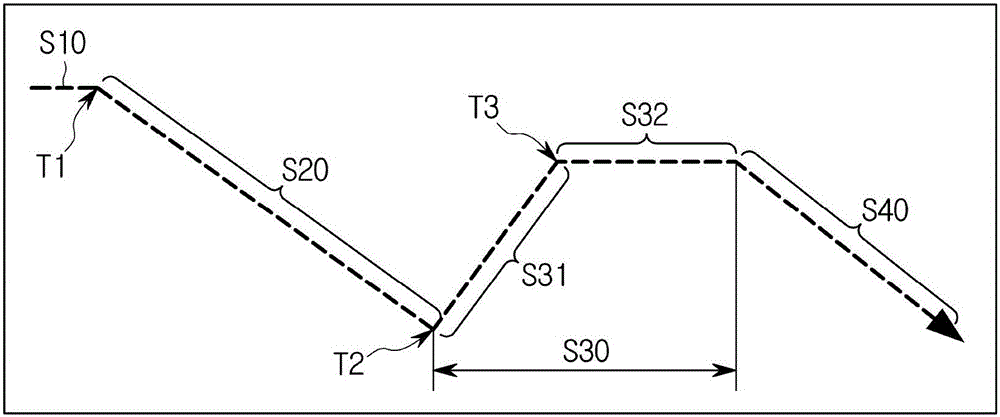

[0107] Figure 11 It is a graph which compares and displays the material variation in the width direction of the hot-rolled coil heat-treated according to the examples of the present invention and the conventional situation. The steel type of the hot-rolled coil 20 is high tensile 980DP, and the size is 2150 mm in outer diameter, 762 mm in inner diameter, and 1200 mm in width. The applied heat treatment conditions are: cooling at room temperature for more than 48 hours after rolling, then reheating, and rapid cooling after holding at 550°C for 4 hours. The air-cooled material without any treatment after rolling has a material deviation of about 250 MPa or more between the edge and the center. When the conventional annealing box (box) is applied, the material deviation in the width direction is reduced to less than 150 MPa. Furthermore, it was confirmed that when the present invention was applied, material softening occurred at large edge portions, and therefore, the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com