The method of preventing steel sticking to the walking beam of the steel pipe walking heat treatment furnace

A technology of heat treatment furnace and walking beam, applied in heat treatment furnace, heat treatment equipment, heat treatment process control and other directions, can solve the problems of pitting on the outer surface of steel pipe, and achieve the effect of saving grinding cost, production cost and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

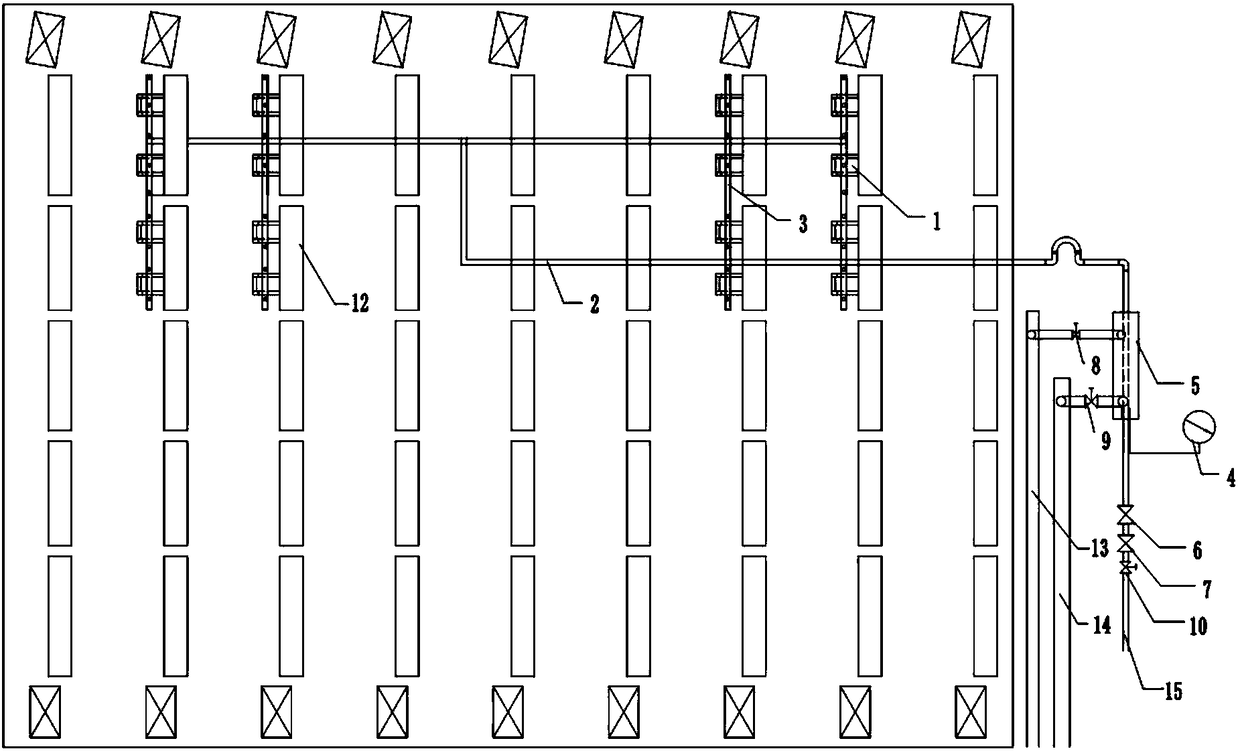

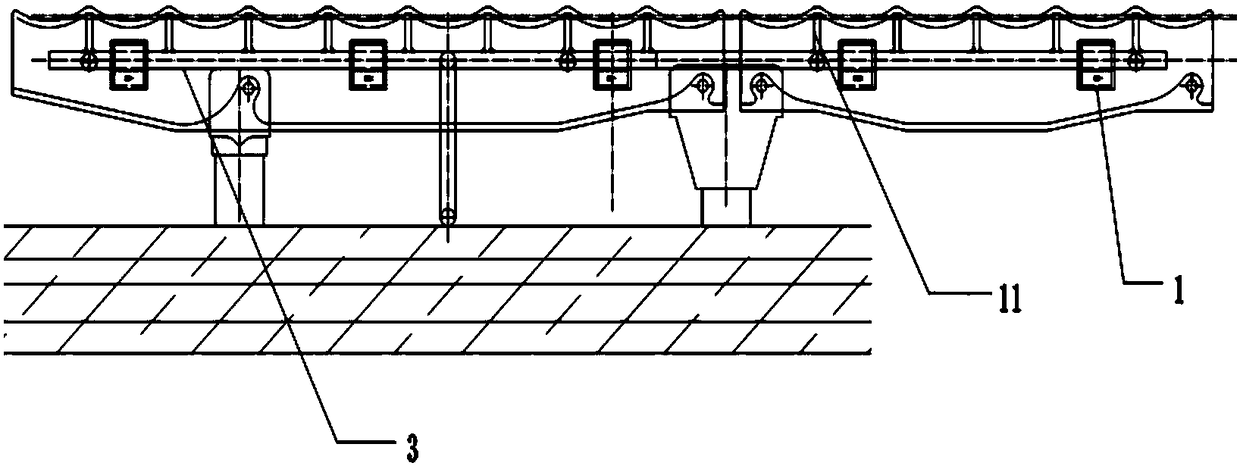

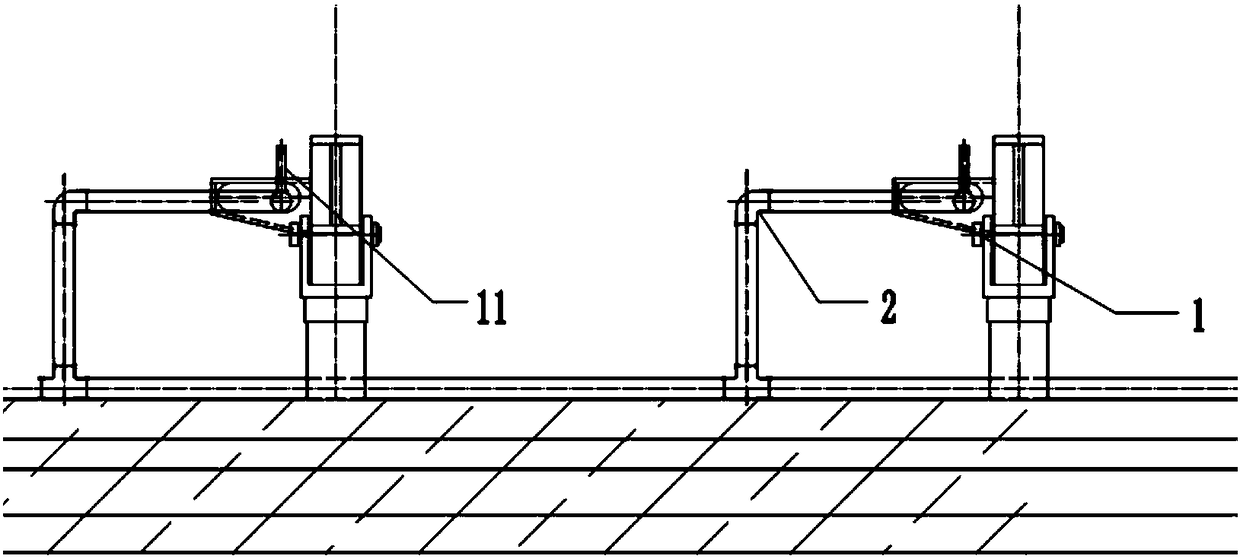

[0026] The method for preventing the walking beam from sticking to steel in the heat treatment of steel pipes according to the present invention will be described in conjunction with the accompanying drawings.

[0027] The design idea of the method for preventing the steel sticking of the walking beam in the heat treatment of the steel pipe of the present invention is to lay pipelines in the high-temperature furnace, and the pipelines are shunted to each walking beam, and hot compressed air is introduced into the furnace to remove the residual heat on the surface of the fixed beam. The oxide scale is thoroughly purged to prevent the scale from accumulating and being rolled by the steel pipe to form nodules, thus eliminating the problem of walking beam sticking to steel from the source, improving the surface quality of the steel pipe, and the actual effect of large-scale production is obvious.

[0028] The method for preventing the steel sticking of the walking beam in the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com