Patents

Literature

68results about How to "Reduce quality objections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

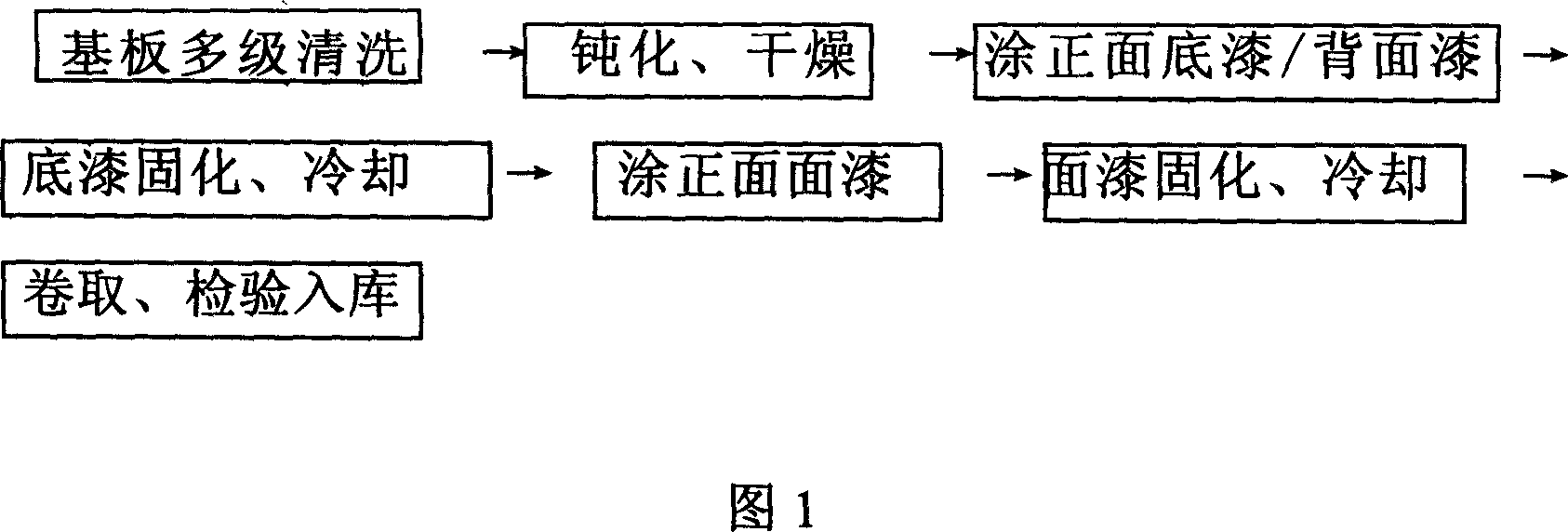

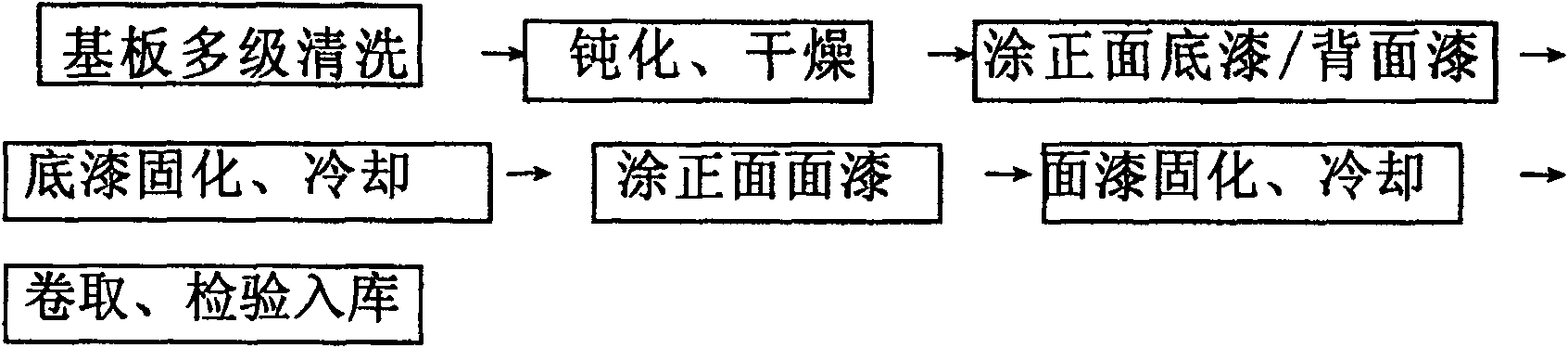

Multi purpose color coating boards, and preparation method

ActiveCN1958284AMeet different performance requirementsEasy to useSynthetic resin layered productsSpecial ornamental structuresEpoxyPollution

A multi-purpose coated color plate used to prepare corrugated plate or sandwich plate is composed of a coated layer on front surface, a basic plate, and a coated layer on back, which uses high-purity (90-99%) epoxy resin as its filming resin. Its preparing process is also disclosed, which features that the Ti-Ni pigments are used to replace Cr-Sr yellow pigment for improving its corrosion resistance and decreasing environmental pollution.

Owner:MAANSHAN IRON & STEEL CO LTD

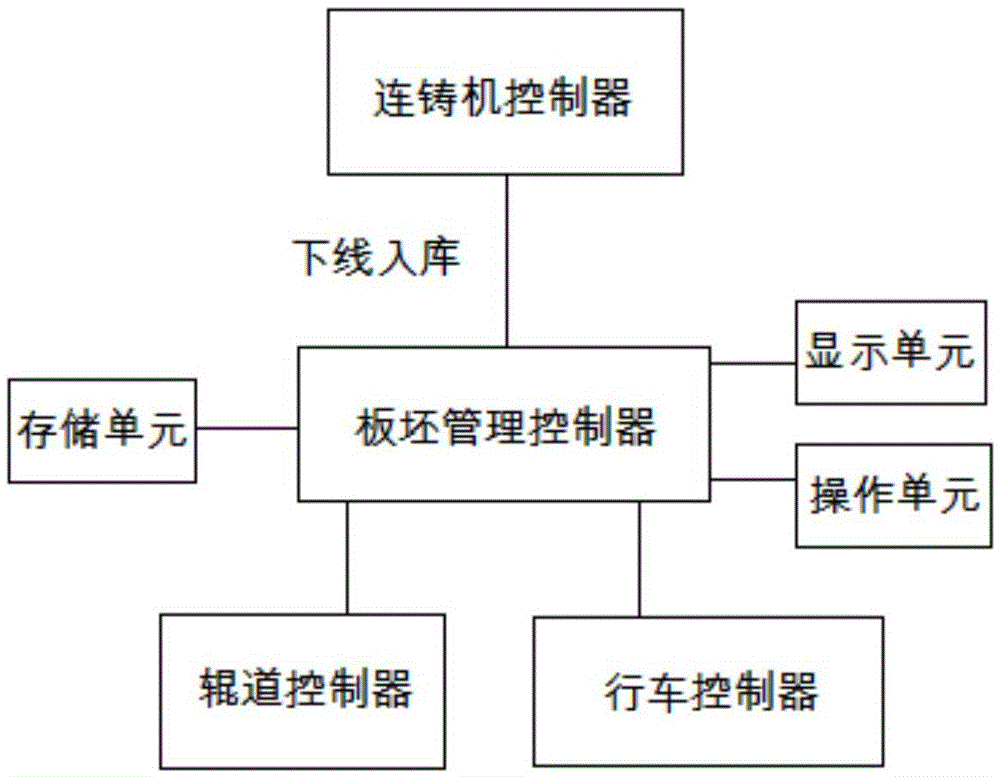

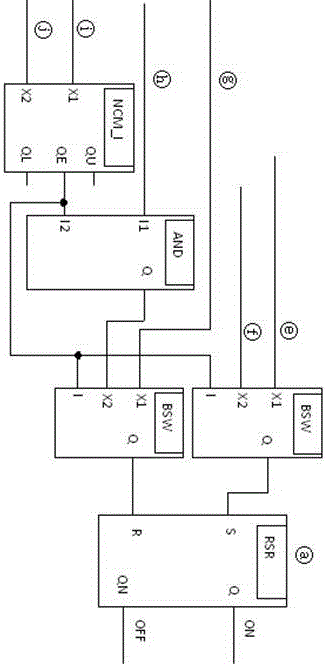

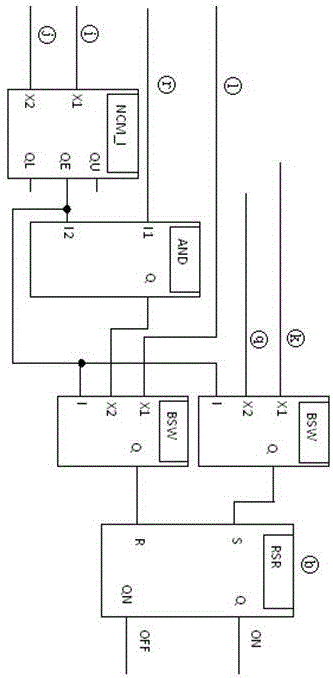

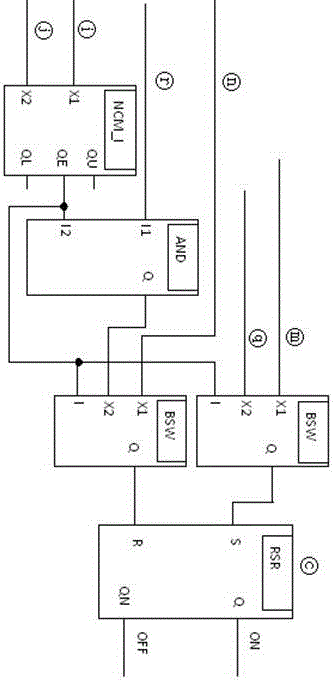

Slab-yard tracking and management system

InactiveCN105527947AGuaranteed correctnessGuaranteed real-timeProgramme total factory controlCommand and controlYard

The present invention discloses a slab-yard tracking and management system which comprises a continuous casting machine controller which outputs slab offline storage information, a slab management controller which receives the slab offline storage information and outputs a storage operation command, a track controller which receives the storage operation command and controls the a roller to transport a slab to a bridge crane operation position, and a bridge crane controller which receives the storage operation command and controls the bridge crane to lift the slab to a stack position to get down. The slab-yard tracking and management system has the advantages that a daily artificial inventory making problem is completely solved, the accuracy and real-time performance of the slab information in a warehouse are fundamentally ensured, and the system has an important meaning for improving product quality and reducing quality objection.

Owner:ANHUI MA STEEL AUTOMATION INFORMATION TECH

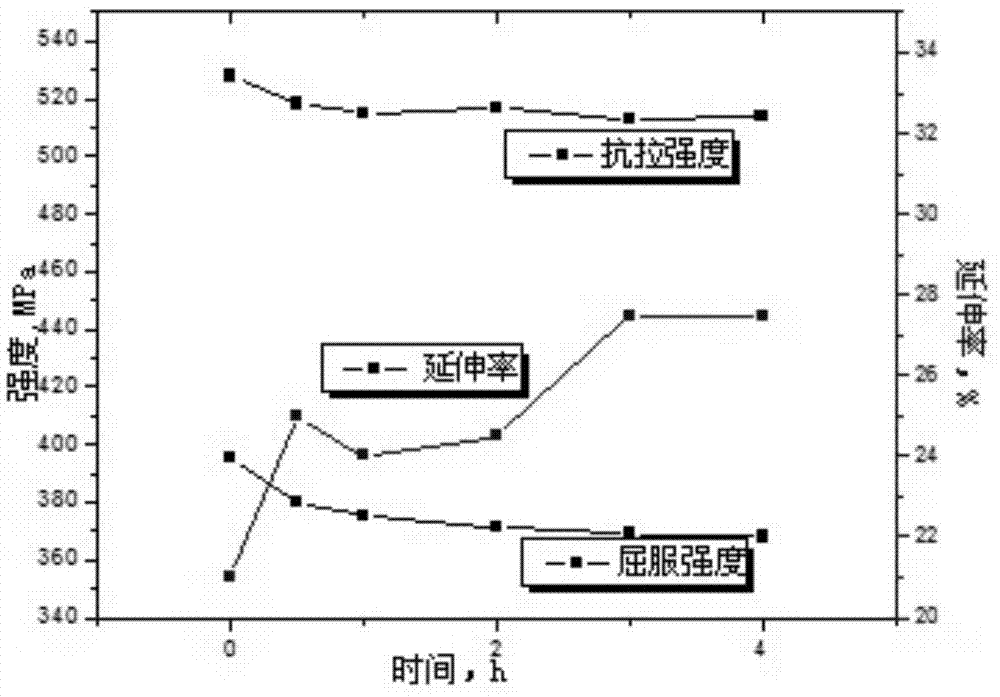

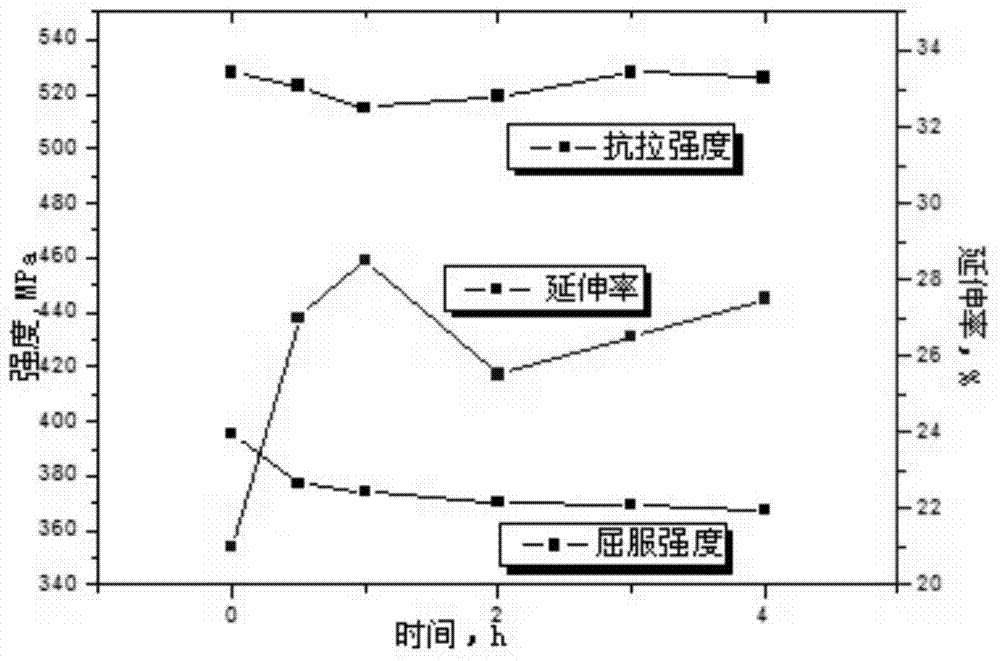

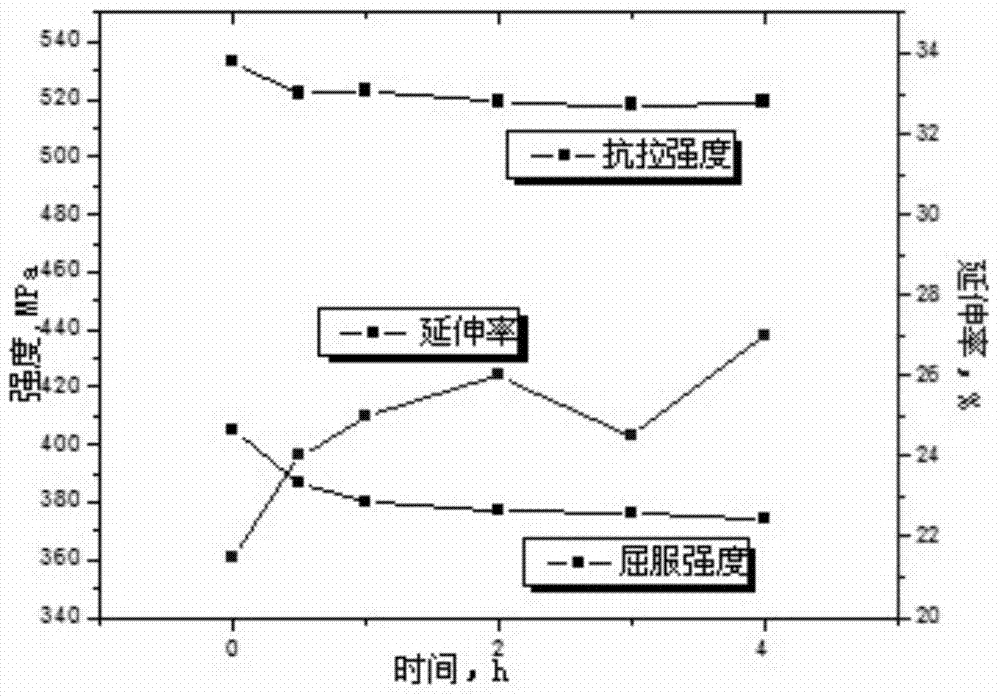

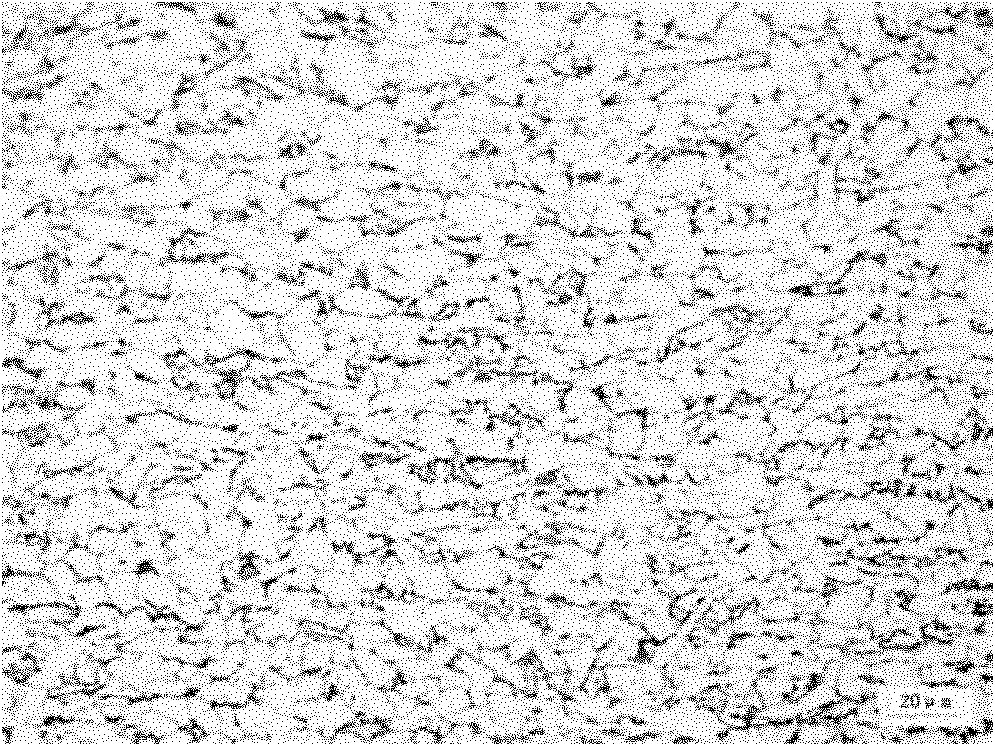

Method of manual accelerated simulation of natural aging of rapid cooling steel plate

ActiveCN103540728AReduce quality objectionsFast simulationHeat treatment process controlNatural agingHeating temperature

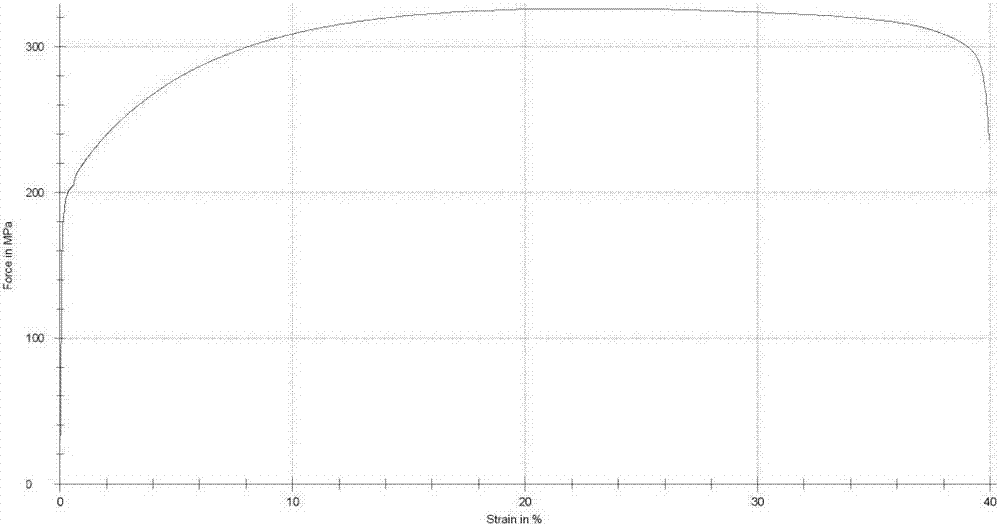

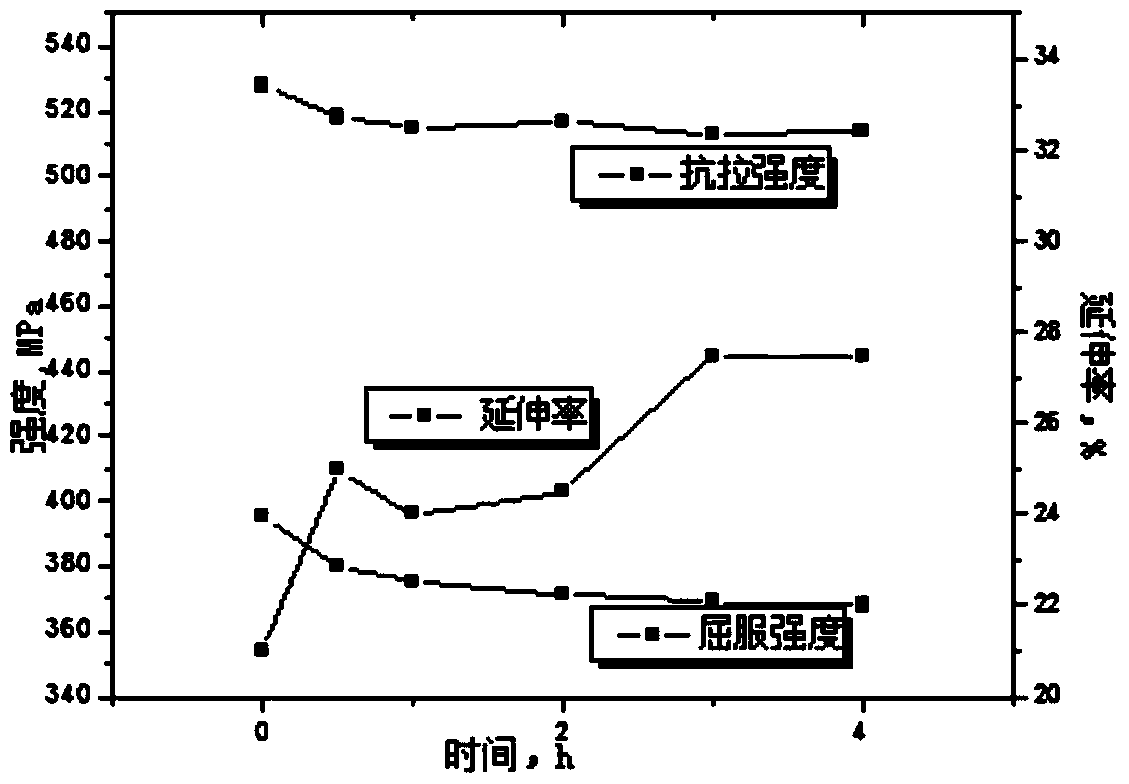

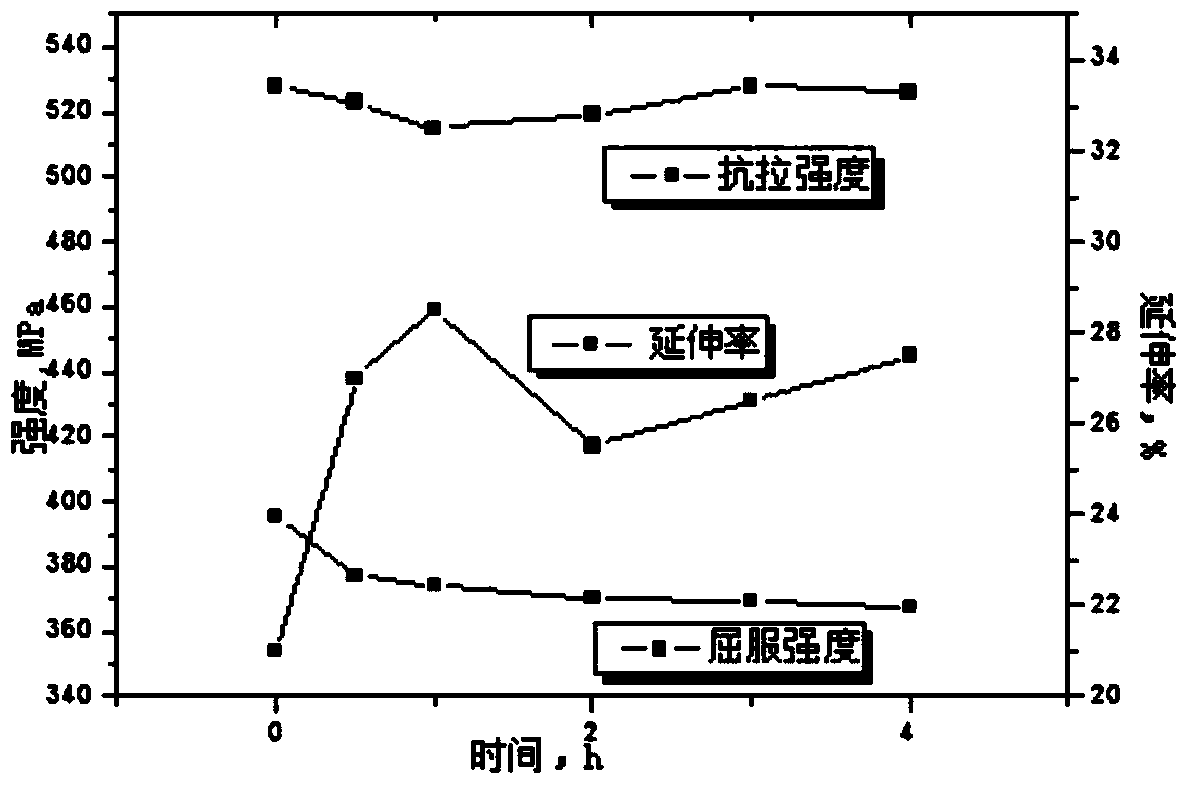

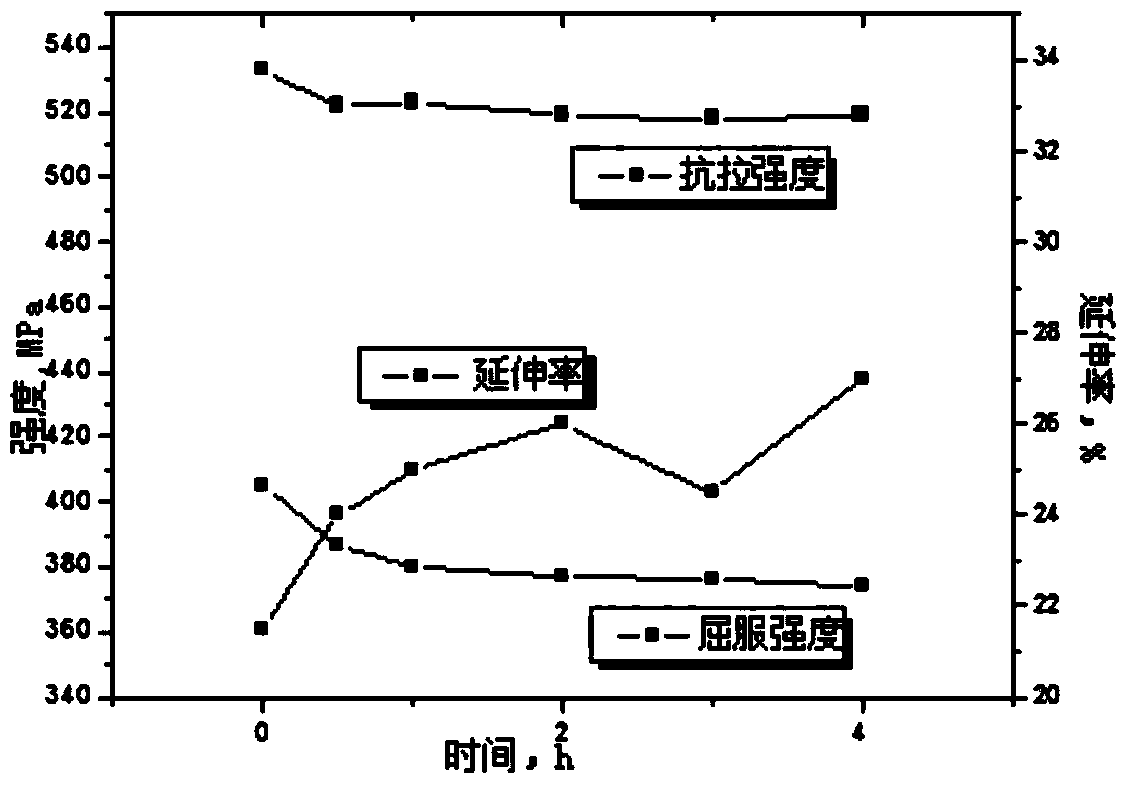

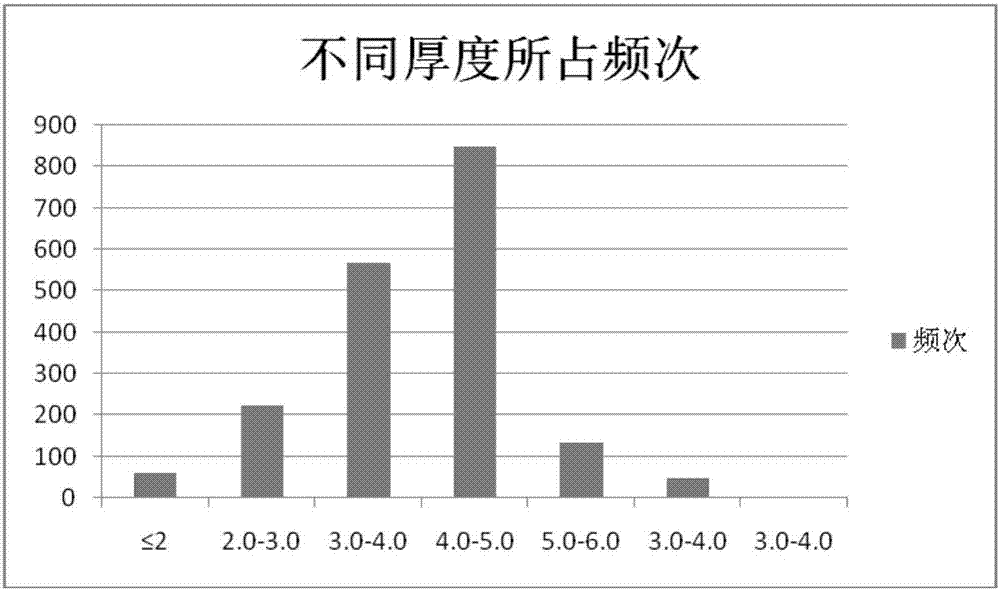

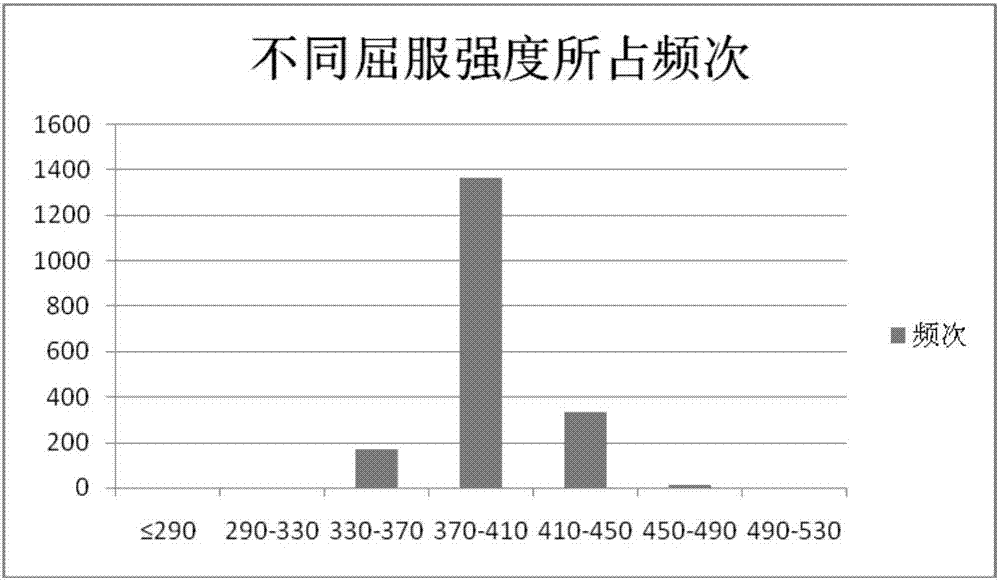

The invention discloses a method of manual accelerated simulation of natural aging of a rapid cooling steel plate. The method comprises a controlled rolling and controlled cooling process, wherein in the controlled rolling and controlled cooling process, the heating temperature is 1150-1250 DEG C, the finish rolling temperature is 810-870 DEG C, the cooling speed is 10-30 DEG C / s, the red-returning temperature is 540-600 DEG C, and the straightening temperature is 520-580 DEG C. The method further comprises an orthogonal control process of manual accelerated simulation of natural aging. The orthogonal control process specifically comprises the following steps: setting the heating temperature at 150-200 DEG C, setting the insulating time of 0.5-5 hours and controlling the cooling speed at less than or equal to 1 DEG C / s. The control method disclosed by the invention can simulate the performance change of the steel plate after natural aging. The trend obtained after implementation is consistent with the change trend of the natural aging performance, so that the method can be used for quickly detecting the aging performance change of the steel plate without affecting the rhythm of production, but also facilitates smoothness of supply of materials.

Owner:NANJING IRON & STEEL CO LTD

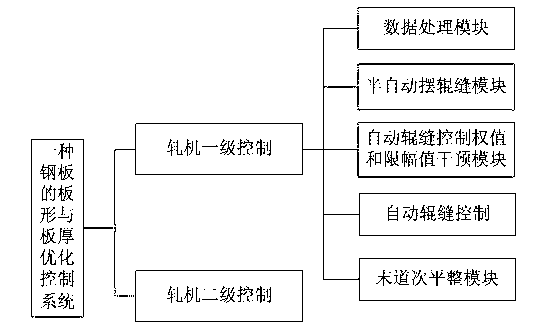

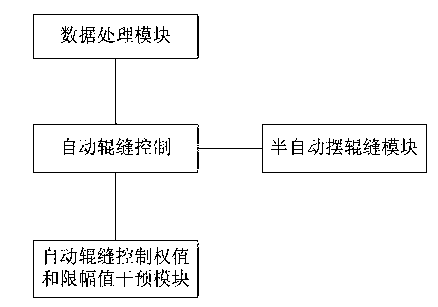

Optimal control system of shape and thickness of steel plate

InactiveCN102989786APlay a leveling roleEasy to controlRoll force/gap control deviceProfile control deviceControl engineeringEconomic benefits

The invention provides an optimal control system of the shape and the thickness of a steel plate, comprising a rolling mill one-stage control and a rolling mill two-stage control for providing a rolling schedule for the rolling mill one-stage control, wherein the rolling mill one-stage control comprises an automatic roll gap control, a data processing module connected with the automatic roll gap control, a finishing pass flattening module for optimizing the plate shape control, a semi-automatic swing roll gap module which is connected with the automatic roll gap control and used for optimizing the plate thickness control and an automatic roll gap control weight and limit value interfering module for adjusting the automatic roll gap control compensation quantity and controlling the limit. By means of the technical scheme of the invention, on the premise that the thickness accuracy is guaranteed, the shape of the heavy-gauge steel plate is improved and particularly the problem of small breaker is greatly improved; meanwhile, the subsequent flattening and cold straightening processes are reduced, the process cost is saved and the economic benefit is considerable; and the quality discrepancy caused by the flatness is reduced and the customer cognition degree is increased.

Owner:JIGANG GRP

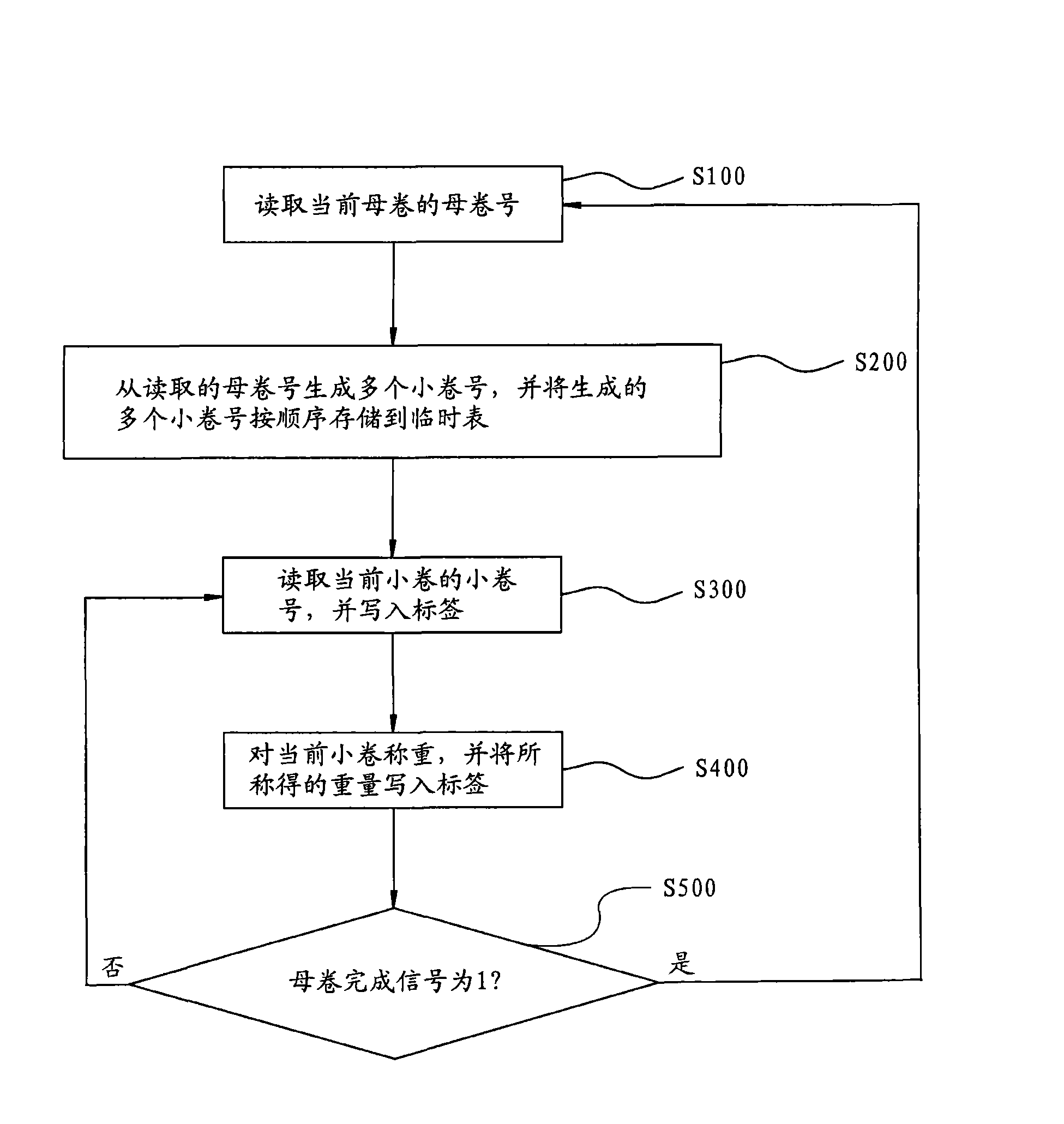

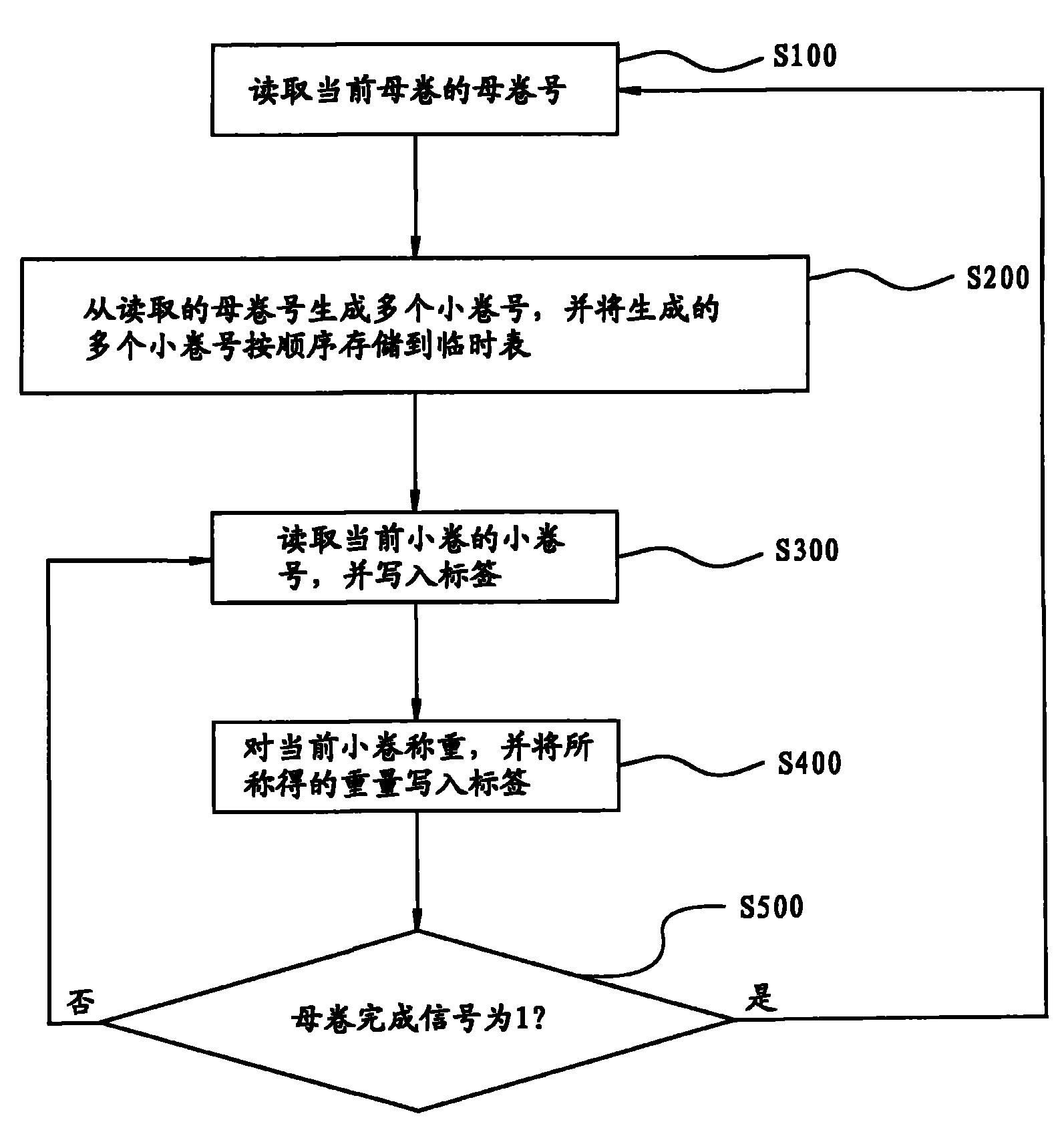

Coil data tracking method for continuous hot-rolled slitting machine

InactiveCN102495955AReduce labor intensityImprove accuracySpecial data processing applicationsMetal rolling arrangementsInformation accuracyUltimate tensile strength

The invention provides a coil data tracking method for a continuous hot-rolled slitting machine to solve the problems in the prior art that the material flow is not matched with the information flow, the labor intensity of operation personnel is large and the like, and the method can alleviate the labor intensity of the operation personnel and can improve the information accuracy. The method comprises the following steps that: a mother coil number of a current mother coil is read by an uncoiler from a previously stored plan table; a plurality of small coil numbers are generated according to the read mother coil number and the quantity of small coils to be divided by the current mother coil, and the generated small coil numbers are stored in a temporary table; when a small coil completion signal which is 1 is received by a coiler, the small coiler number of a current small coil is read by the coiler from the temporary table to be written into a label of the current small coil; an electronic scale weighs the current small coil, and the measured weight is written into the label of the current small coil; when a mother coil completion signal is not 1, data tracking is executed for a next small coil; and if the mother coil completion signal is 1, data tracking is executed for a next mother coil.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Method for producing hot-rolled steel coil

InactiveCN102127679AImprove plasticityImprove toughnessProcess efficiency improvementInsertion depthNitrogen

The invention relates to a method for producing a hot-rolled steel coil, which comprises the following steps of: 1) designing components, pretreating molten iron, smelting in a converter, switching nitrogen and argon, and tapping to obtain molten steel; 2) performing continuous casting on the molten steel to obtain a plate blank, wherein the content of the molten steel in a continuously cast intermediate ladle is controlled to be between 8 and 15t and the liquid level is controlled to be between 200 and 350mm when the intermediate ladle is not poured; and pouring is protected in the whole process, and the insertion depth of a long nozzle is between 300 and 400mm; 3) heating the plate blank; and 4) rolling and curling the heated plate blank. By the method, the content of C and Mn in the components of Q235q-D steel is reduced, the comprehensive performance of the Q235q-D steel is improved by appropriate rolling process and controlled cooling process, and a low-cost and high-performance Q235q-D hot-rolled steel coil is produced.

Owner:NINGBO IRON & STEEL

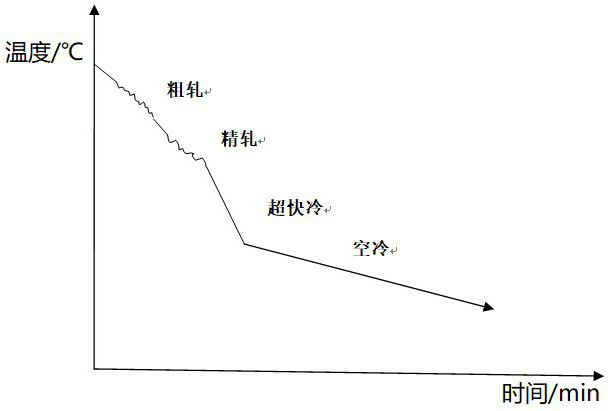

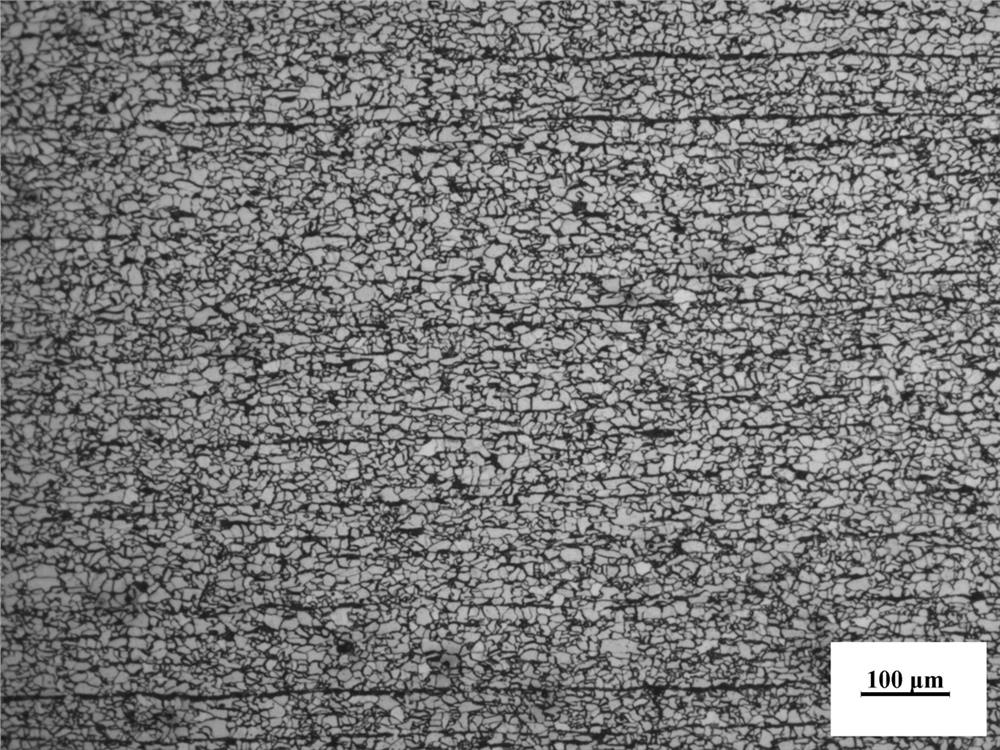

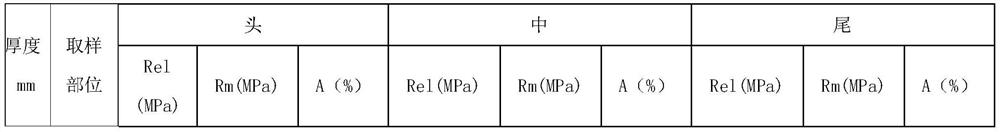

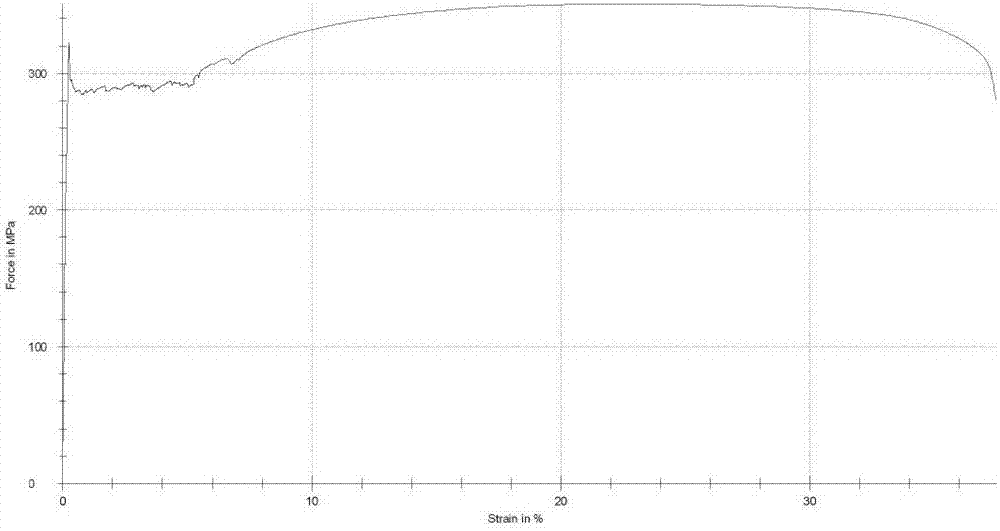

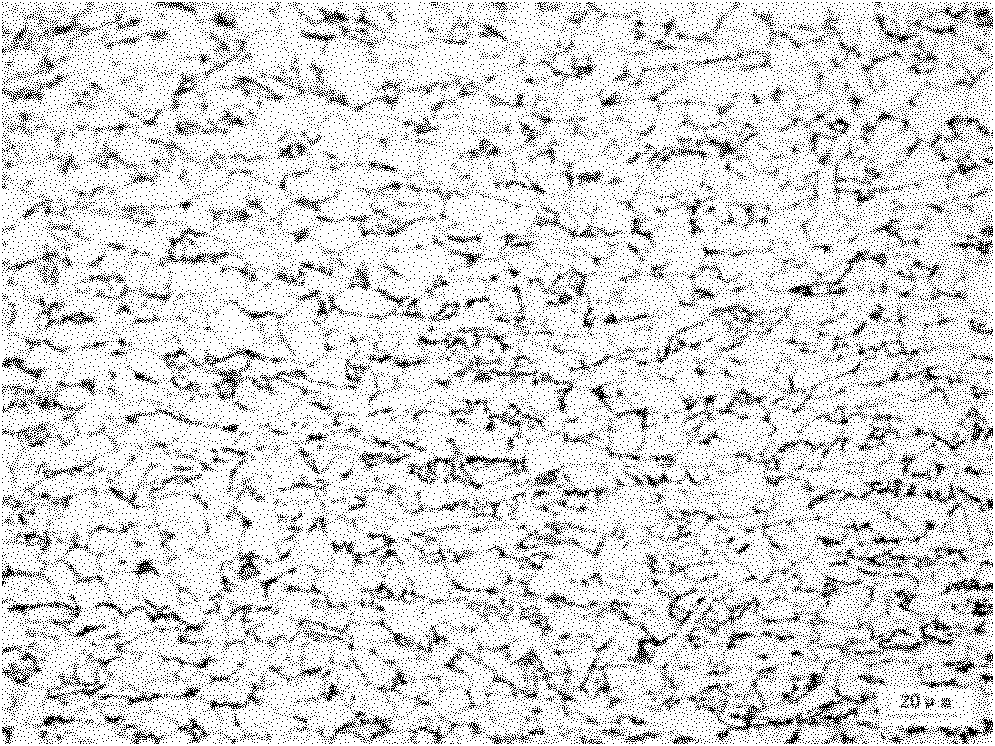

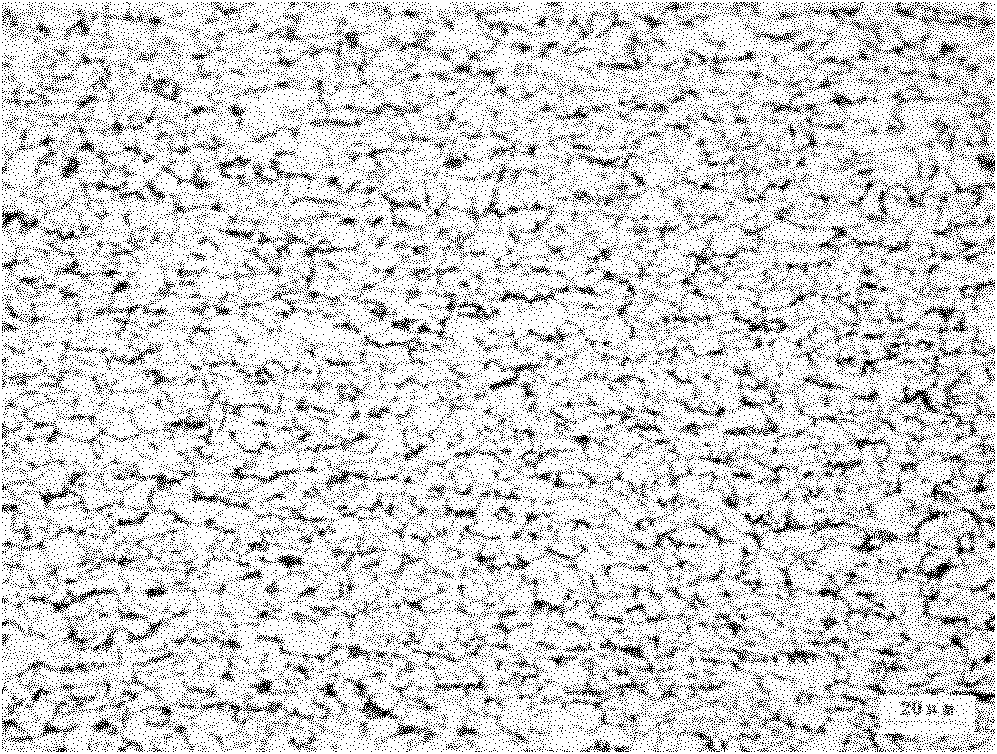

Rolling process of Ti-containing low alloy steel

ActiveCN111647806AImprove performanceGood welding performanceHeat treatment process controlSteelmakingMetallurgy

The invention relates to a rolling process of Ti-containing low alloy steel. The steel comprises the following components in percent by mass: 0.13-0.15% of C, 0.20-0.40% of Si, 0.70-0.90% of Mn, lessthan or equal to 0.020% of P, less than or equal to 0.020% of S, 0.003-0.020% of Al, 0.045-0.065% of Ti, less than or equal to 0.30% of CEV and the balance Fe and inevitable impurity elements. The rolling process comprises the following steps of S1, producing a proper slab in a steelmaking step; S2, directly heating the slab in the step 1 at a high temperature; S3, roughly rolling the slab heatedat the high temperature in the step 2; S4, carrying out finish rolling on the roughly rolled slab in the step 3; S5, carrying out ultra fast cooling on the slab after finish rolling in the step 4; andS6, cooling the slab to 800-820 DEG C in the step 5 and carrying out air cooling on the slab. The rolling process overcomes the defects in the prior art and meets the demand of steel rolling production of a low cost low alloy steel plate.

Owner:HEBEI PUYANG IRON & STEEL

Long material production process control system

InactiveCN105404265AImprove transfer efficiencyImprove accuracyProgramme total factory controlWire rodApplication server

The invention relates to a long material production process control system. The system comprises an application server, a database server, a client computer, a bar code scanner and a bar code printer, wherein the application server and the database server are accessed to an enterprise computer network through a switch, and the client computer is accessed to the enterprise computer network through a router; and the client computer is connected with the application server through a browser for accessing system functions and performing service requesting, and the application server, after receiving a request and performing logic processing, returning a result to the client computer. According to the invention, the whole production process of a whole long material can be tracked by use of a computer system and a bar code system, wire rods and bars can be better produced in a planning way, batch management of the wire rods and the bars is reinforced, the phenomenon of mixed steel of various batches is put to an end, and the phenomenon of inconsistency between weighing information and objects is eliminated. Quality information is transmitted through a computer, and the quality data transmission efficiency and the correct rate are improved.

Owner:ANHUI MA STEEL AUTOMATION INFORMATION TECH

Control method of eliminating yield point elongation at front part and rear part of weld joint of cold-rolled strip steel

InactiveCN107321789AEasy to operateGuarantee product qualityRoll mill control devicesMetal rolling arrangementsStrip steelRhythm

The invention relates to a control method of eliminating yield point elongation at the front part and the rear part of a weld joint of cold-rolled strip steel and belongs to the technical field of cold-rolled strip steel production control. According to the technical scheme, the control method comprises the following steps: when the strip steel is continuously produced, an operator determines the minimum scrap cutting knife number at a strip tail and the minimum scrap cutting knife number at a strip head according to the following formula in light of speed of the weld joint passing through a temper mill, and then the operator sets the minimum scrap cutting knife number at the strip tail and the minimum scrap cutting knife number at the strip head at an outlet for roll dividing: Y1 is greater than or equal to ROUNDUP{(0.58595+0.01384*X) / 0.45, 0}; Y2 is greater than or equal to ROUNDUP{(5.48925-0.04198*X+0.000346*X<2>) / 0.45, 0}, wherein Y1 is the minimum scrap cutting knife number at the strip tail, Y2 is the minimum scrap cutting knife number at the strip head and X is the speed of the weld joint passing through the temper mill, the unit of the speed is m / min; 0.45 is the length of scrap cut at the outlet every time and the unit is m. The control method provided by the invention has the beneficial effects that the control method is simple; the operator sets the speed of the weld joint passing through the temper mill according to rhythm of production and sets the corresponding minimum scrap cutting knife numbers at the front part and the rear part of the weld joint at the outlet, so that objection about quality caused by defects of fish scales as the head and tail are not thoroughly cut off is reduced while the product quality is guaranteed, and meanwhile, the production efficiency is increased.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

An Artificial Accelerated Simulation Method for Natural Aging of Rapidly Cooled Steel Plates

ActiveCN103540728BReduce quality objectionsFast simulationHeat treatment process controlNatural agingHeating temperature

The invention discloses a method of manual accelerated simulation of natural aging of a rapid cooling steel plate. The method comprises a controlled rolling and controlled cooling process, wherein in the controlled rolling and controlled cooling process, the heating temperature is 1150-1250 DEG C, the finish rolling temperature is 810-870 DEG C, the cooling speed is 10-30 DEG C / s, the red-returning temperature is 540-600 DEG C, and the straightening temperature is 520-580 DEG C. The method further comprises an orthogonal control process of manual accelerated simulation of natural aging. The orthogonal control process specifically comprises the following steps: setting the heating temperature at 150-200 DEG C, setting the insulating time of 0.5-5 hours and controlling the cooling speed at less than or equal to 1 DEG C / s. The control method disclosed by the invention can simulate the performance change of the steel plate after natural aging. The trend obtained after implementation is consistent with the change trend of the natural aging performance, so that the method can be used for quickly detecting the aging performance change of the steel plate without affecting the rhythm of production, but also facilitates smoothness of supply of materials.

Owner:NANJING IRON & STEEL CO LTD

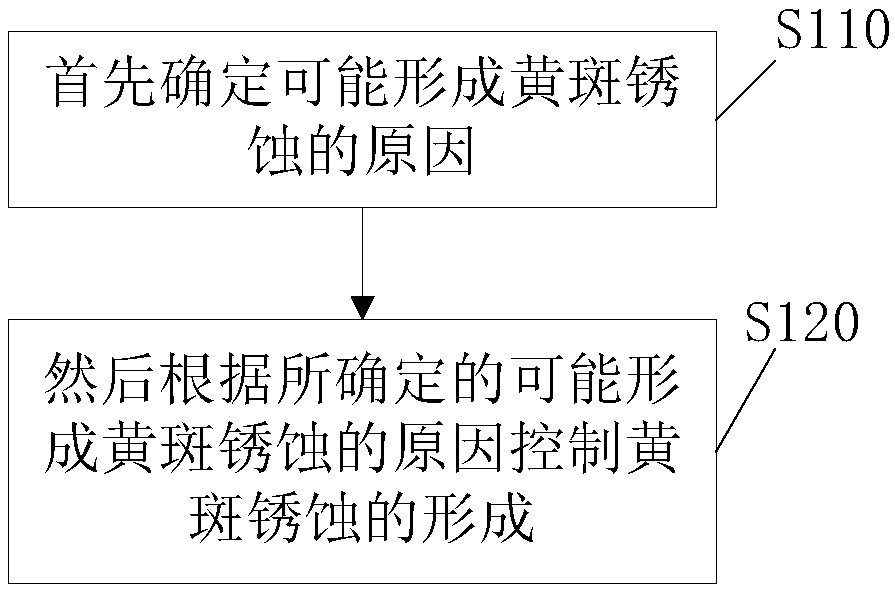

Control method for macular corrosion of cold rolling pickling machine set

ActiveCN106367768AReduce quality objectionsReduce the conversion rateDrying solid materials without heatSpraying apparatusHigh concentrationHigh humidity

The invention provides a control method for macular corrosion of a cold rolling pickling machine set. The control method comprises the following steps: first, determining possible reasons for formation of the macular corrosion, and then controlling the formation of the macular corrosion according to the possible reasons for the formation of the macular corrosion, wherein the possible reasons for the formation of the macular corrosion comprises the following seven types: the macular corrosion formed in a low-speed process of a process stage, the macular corrosion formed by over-high concentration of residual C1 on the surface of band steel, the macular corrosion formed by excessive temperature difference between a water temperature and an acid temperature in a bleaching stage, the macular corrosion formed by accidental shutdown or slow speed, the macular corrosion formed by low pressure of a squeezing roller and low temperature of a drying machine in the process stage, the macular corrosion formed by instability of voltage of an electrostatic oiler, and the macular corrosion formed by high humidity in a working field. By utilizing the control method for the macular corrosion of the cold rolling pickling machine set, the problems of great loss and the like caused by the defect of the macular corrosion of the band steel can be solved.

Owner:RIZHAO BAOHUA NEW MATERIAL CO LTD

Method for producing hot-rolled steel coils

InactiveCN102212748AReduce dosageSimple methodRoll mill control devicesManufacturing convertersNiobiumPosition control

The invention relates to a method for producing hot-rolled steel coils. The method comprises the following steps of: 1) designing components, pre-treating molten iron, smelting in a converter with nitrogen and argon switching, and tapping to obtain molten steel; 2) performing continuous casting on the molten steel to obtain a plate blank, wherein when pouring of a continuously cast intermediate ladle is stopped, the molten steel quantity of the intermediate ladle is controlled at 8 to 15 tons, the liquid level is 200 to 350 millimeters, full-process protective pouring is adopted, and the inserting depth of a long nozzle is 300 to 400 millimeters; 3) heating the plate blank; and 4) rolling the heated plate blank, and coiling. A thermo-mechanical control process + remote position control (TMCP+RPC) rolling process is adopted in the method; by using micro niobium treatment, the content of C and the content of Mn are greatly reduced, and the production cost is reduced; the obtained Q345q-C hot-rolled steel coils have good plasticity and toughness, and the elongation of the steel coils can be improved by over 8 percent; and meanwhile, the welding property of the steel coils is improved, and good surface quality of a continuously cast bloom is ensured.

Owner:NINGBO IRON & STEEL

Control method for improving surface quality of hot rolled variety steel

ActiveCN106475431AMeet the normal cooling functionSolve the problem of surface rustTemperature control deviceWork cooling devicesStrip steelHot rolled

The invention relates to a control method for improving the surface quality of hot rolled variety steel and belongs to the field of steel rolling. The control method comprises the steps of: firstly judging whether the material code of hot rolled variety steel fed by a secondary computer is equal to that of easily corroded variety steel or not; if so, closing cooling water for a G roller bed when a finish rolling final stand load is turned on; opening cooling water for the G roller bed when the finish rolling final stand load is turned off; closing cooling water for a pinch roll, a wrapper roller and coiling block equipment when a signal that the head of strip steel reaches a heat inspection window in front of a coiling machine is switched on; and opening cooling water for the pinch roll, the wrapper roller and the coiling block equipment when a signal that the tail of strip steel reaches the heat inspection window in front of a coiling machine is switched on. According to the control method provided by the invention, the surface corrosion of an inner layer of a steel coil of variety steel is avoided, the surface quality of a finished product is improved, the percent of pass of the steel coil is improved, the objection of customer quality is reduced, and a good benefit is gained.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for producing hot rolled steel coils

The invention relates to a method for producing hot rolled steel coils. The method comprises the following steps: 1) designing the components, pretreating molten iron, then carrying out converter smelting, carrying out nitrogen / argon changing over and carrying out tapping to obtain molten steel; 2) continuously casting the molten steel to obtain slabs, controlling the weight of the molten steel in the tundish to be 8-15t when casting of the continuous casting tundish is stopped, ensuring the liquid level to be 200-350mm; carrying out protective casting in the whole course and ensuring the insertion depth of the long nozzle to be 300-400mm; 3) heating the slabs; and 4) finally rolling and curling the heated slabs, thus obtaining the hot rolled steel coils. The method has the following beneficial effects: the TMCP (thermo-mechanical control process)+RPC (relaxation-precipitation-controlling phase transformation) rolling processes are adopted and the contents of C and Mn are substantially reduced by utilizing micro-niobium treatment, thus reducing the production cost; and the Q345R hot rolled steel coils obtained by the method have excellent plasticity and toughness, the elongation of the hot rolled steel coils is improved by more than 8%, and at the same time, the welding property of the materials is improved and good surface quality of the continuous casting slabs is ensured.

Owner:NINGBO IRON & STEEL

Low-cost and high-performance SPA-H hot rolled steel coil and preparation method thereof

InactiveCN106947915AImprove plasticityImprove toughnessManufacturing convertersProcess efficiency improvementLaminar coolingPre treatment

The invention relates to a low-cost and high-performance SPA-H hot rolled steel coil and a preparation method thereof. The low-cost and high-performance SPA-H hot rolled steel coil comprises, by mass, 0.07%-0.095% of C, 0.25%-0.35% of Si, 0.38%-0.48% of Mn, 0.085%-0.105% of P, 0.007% of S or the less, 0.25%-0.35% of Cu, 0.08%-0.20% of Ni, 0.50%-0.60% of Cr, 0.015%-0.045% of Als and the balance Fe and inevitable impurities. The preparation method comprises the steps of composition design, hot metal pretreatment, converter smelting, ladle furnace treatment, continuous casting, hot continuous rolling, laminar cooling and reeling, and the SPA-H hot rolled steel coil is obtained. The SPA-H hot rolled steel coil has excellent plasticity and toughness, cold processing performance is improved, the problem of bending cracking of large deformation in the using process of the SPA-H steel coil is avoided, quality objections are reduced, and comprehensive performance of SPA-H steel is improved.

Owner:NINGBO IRON & STEEL

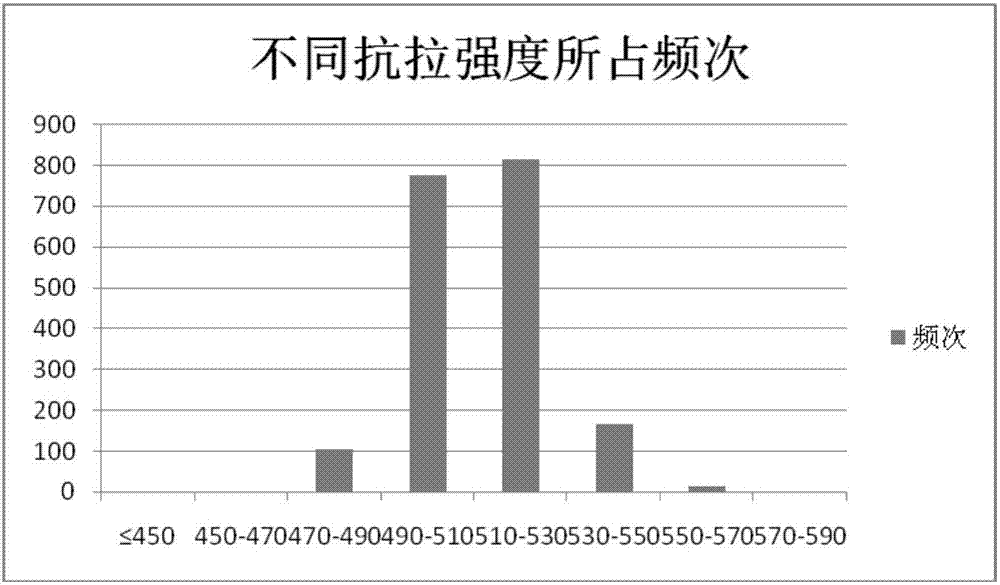

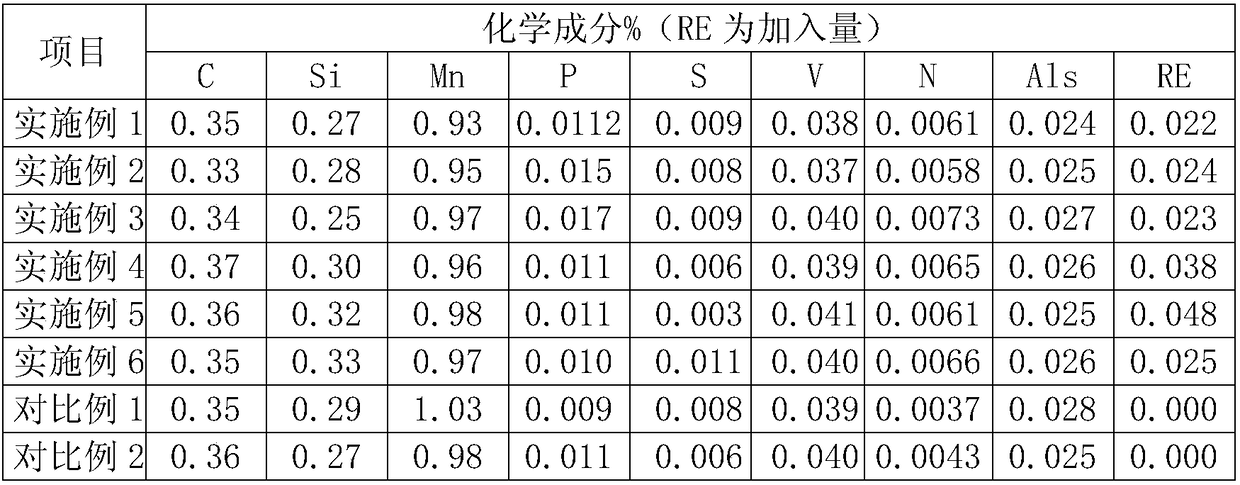

Axle shaft steel for railway vehicle and production method of axle shaft steel

The invention discloses axle shaft steel for a railway vehicle and a production method of the axle shaft steel. The axle shaft steel comprises, by weight percentage, 0.33-0.38% of C, 0.15-0.40% of Si,0.90-1.05% of Mn, less than or equal to 0.020% of P, less than or equal to 0.020% of S, 0.030-0.050% of V, 0.015-0.035% of Als, 0.0040-0.0090% of N and the balance iron and inevitable impurity elements, wherein the adding amount of RE in molten steel ranges from 0.020% to 0.050%. A production process of the axle shaft steel comprises the steps of smelting, LF and RH refining, protected pouring, pressure machining, rough machining, heat treatment, finish machining and inspection and warehousing. By means of the method, the defects that the surface magnetic mark rejection rate of existing axleshafts is high, and the lateral impact energy is low can be overcome; surface magnetic mark rejects of the railway vehicle axle shafts can be obviously reduced; comprehensive mechanical performance ofthe axle shaft steels is improved, in particular, the lateral impact energy is increased, and the lateral impact energy guarantee value is greater than or equal to 40 J; and thus, use safety of the axle shafts can be improved.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Method for producing hot rolled steel coil

The invention relates to a method for producing a hot rolled steel coil. The method comprises the following steps of: 1) designing components, pretreating molten iron, smelting in a converter, switching between nitrogen and argon, and performing tapping to obtain molten steel; 2) performing continuous casting on the molten steel to obtain a plate blank, controlling tundish molten steel amount to be between 8t and 15t and liquid level to be between 200mm and 350mm when a continuous casting tundish stops pouring, and pouring under protection in the entire process, wherein the length of an inserted part of a long nozzle is between 300mm and 400mm; 3) heating the plate blank; and 4) finally rolling the heated plate blank and winding to obtain the hot rolled steel coil. In the method, a thermo mechanical control process (TMCP) and a relaxation-precipitation-control (RPC) rolling process are adopted, and C content and Mn content are greatly reduced by micro niobium treatment, so that production cost is reduced; the Q345q-E hot rolled steel coil produced by the method has high plasticity and toughness, and the elongation rate of the hot rolled steel coil is improved by more than 8 percent; meanwhile, the welding properties of materials are improved, and high surface quality of a continuous casting blank is guaranteed.

Owner:NINGBO IRON & STEEL

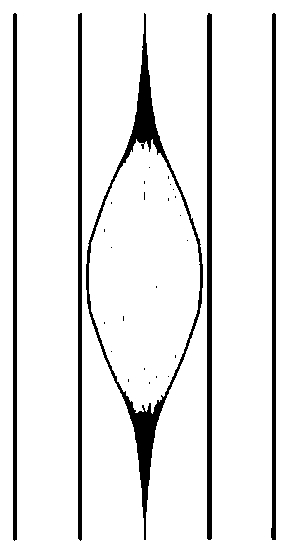

Concave press die and sizing machine

InactiveCN110293136AReduce distanceImprove surface quality and yieldMetal rolling stand detailsRoll mill control devicesSteel platesSheet steel

The invention discloses a concave press die and a sizing machine. The concave press die and the sizing machine are applied to pressure sizing of a hot rolled steel plate blank. The surface of the side, facing the hot rolled steel plate blank, of the concave press die is provided with a forming groove; the two ends of the forming groove are respectively open at the two end surfaces of the concave press die in the rolling direction of the hot rolled steel plate blank; and the notch width of the forming groove is larger than the thickness of the hot rolled steel plate blank; and the groove bottomwidth of the forming groove is smaller than the thickness of the hot rolled steel plate blank. The concave press die and the sizing machine effectively solve the defect of black lines at the edges ofhot-rolled steel plates, improve the surface quality and the yield of the hot-rolled steel plates, and eliminate the quality objection of users.

Owner:武汉钢铁有限公司

Movable device displacement measurement method as well as rough mill and gate footstep shear using same

InactiveCN108788273AOvercoming Position Measurement ErrorsReduce impact damageMeasuring devicesShearing machinesSheet steelEngineering

The invention discloses a movable device displacement measurement method as well as a rough mill and a gate footstep shear using the same. According to the measurement method, a stay wire coder and aPLC system are provided; the stay wire coder is installed at the fixed end of a movable device; a stay wire of the stay wire coder is fixed to the movable end of the movable device so that the stay wire moves with the movable end; when the stay wire moves with the movable end, the stay wire coder is used for generating signal changes; a signal template of the PLC system is used for acquiring the variation of signals; and displacement changes of the movable end are obtained by calculation. The method effectively overcomes position measurement errors caused by mechanical clearances. After usingthe method, the rough mill can realize precise measurement of the width of a side guide plate, reduces the phenomenon of cambering generated in a rolling process and improves the product quality. After using the method, the gate footstep shear improves the width measurement precision of a steel plate.

Owner:NANJING IRON & STEEL CO LTD

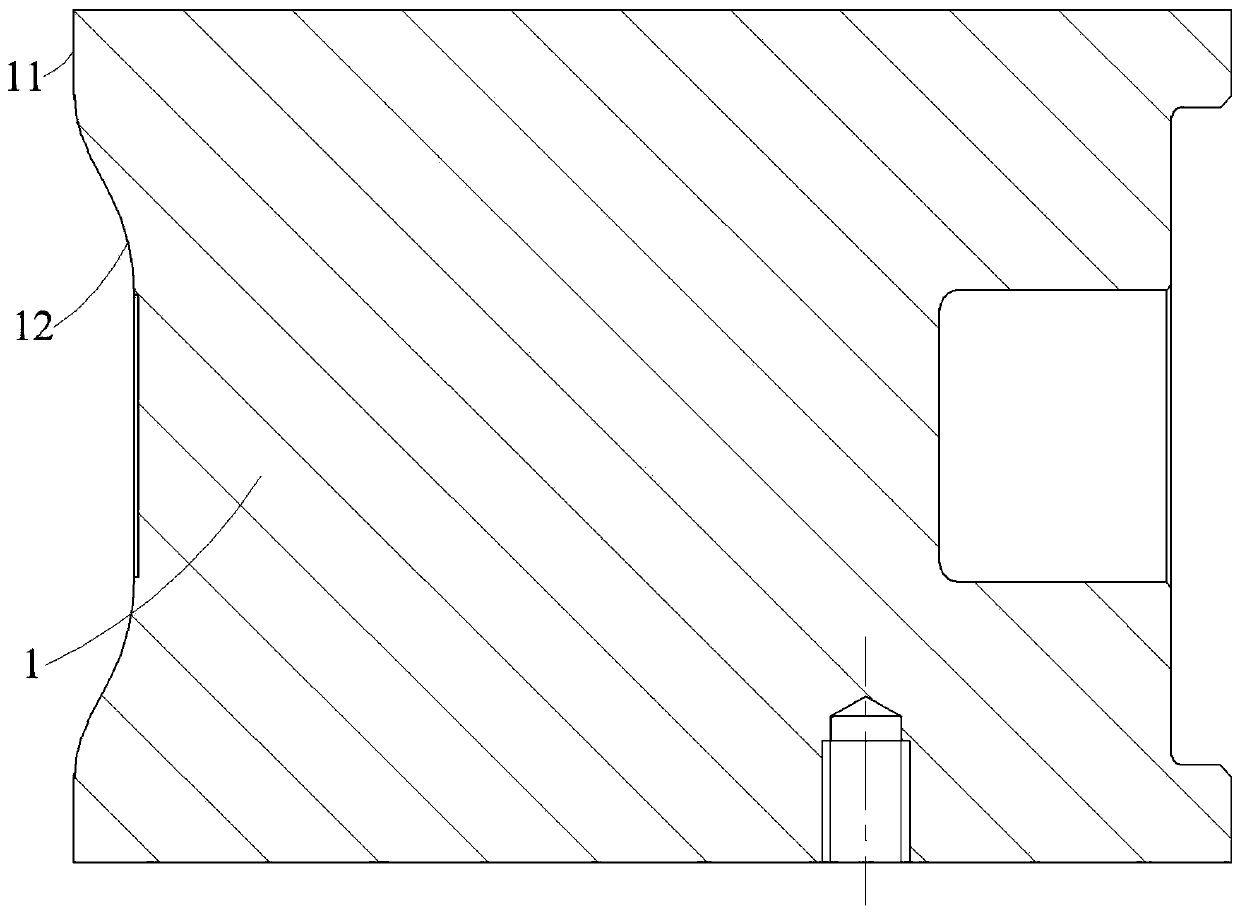

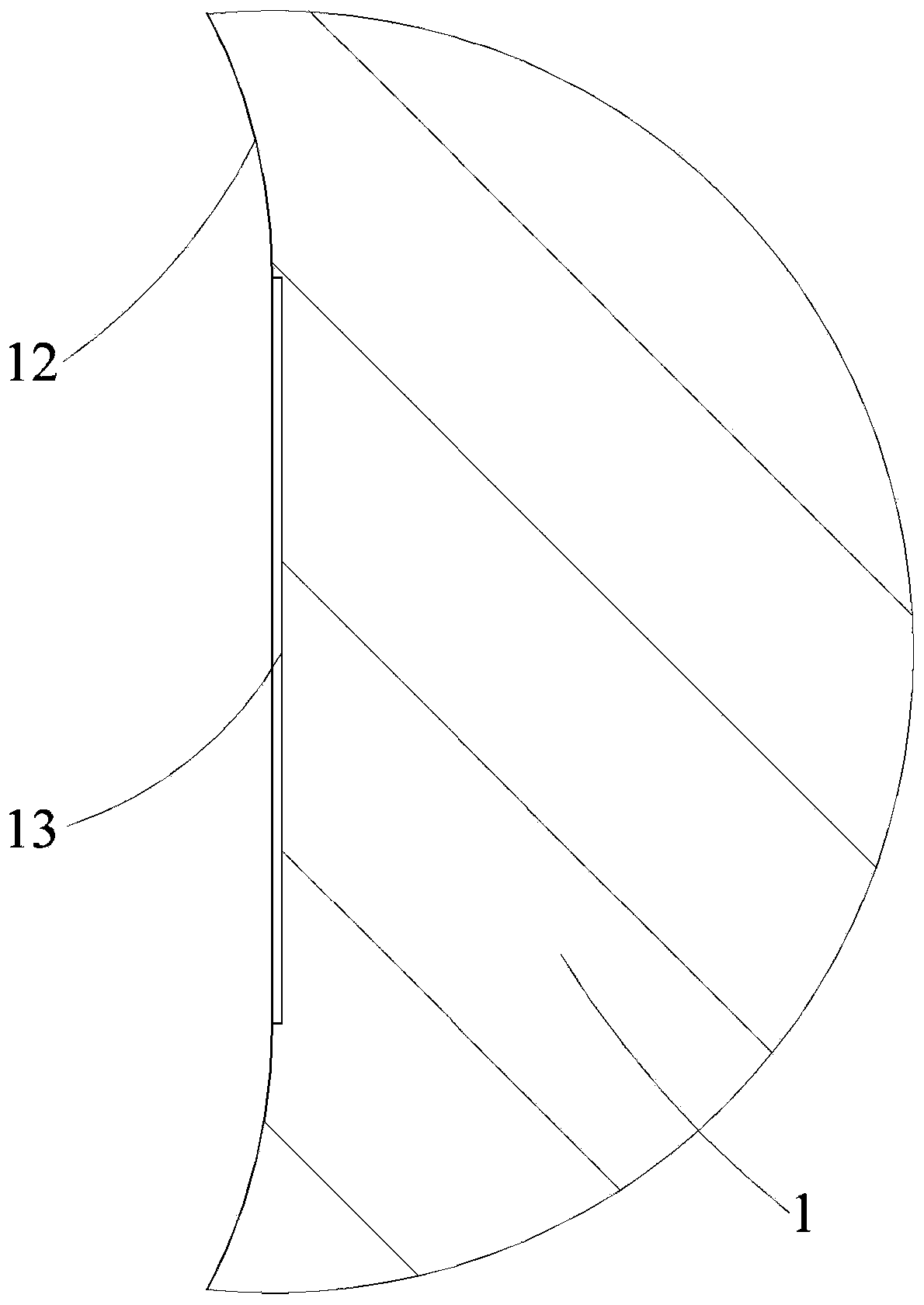

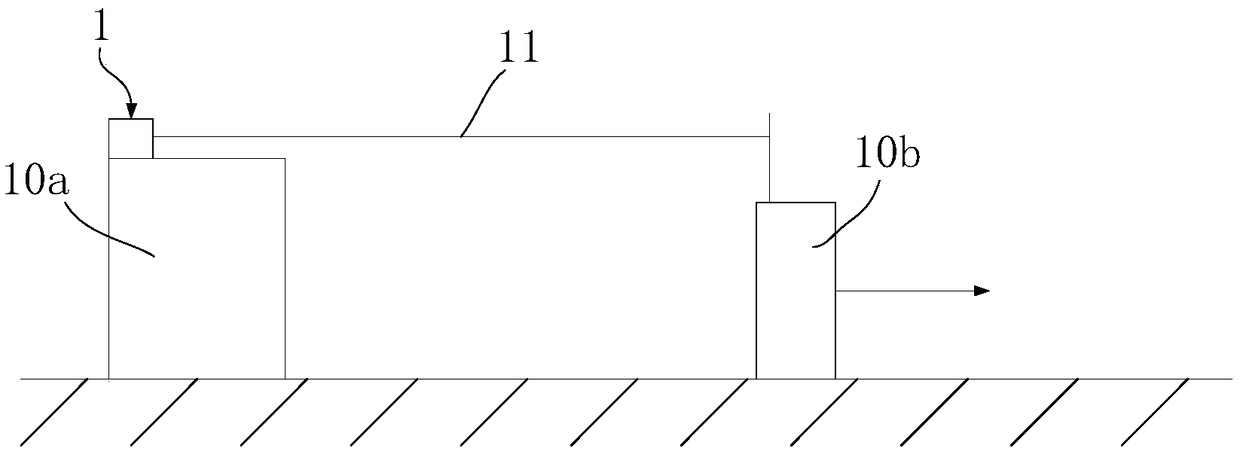

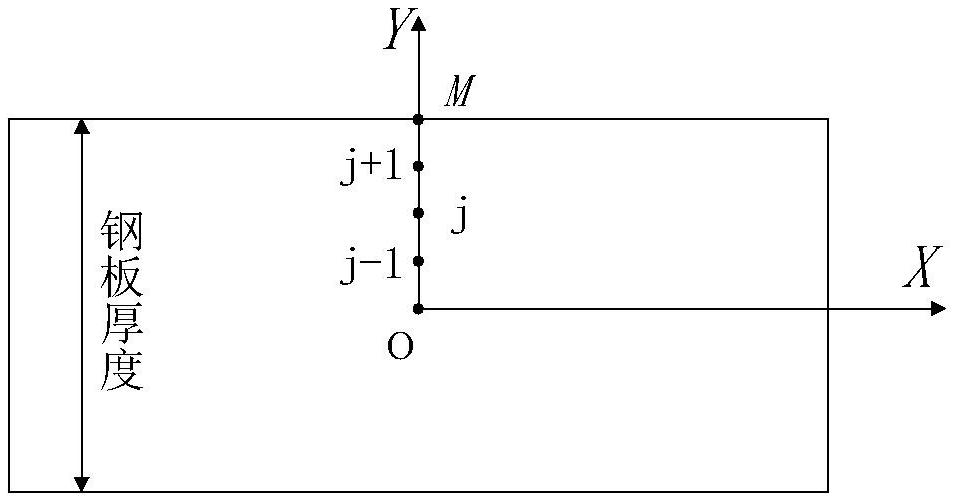

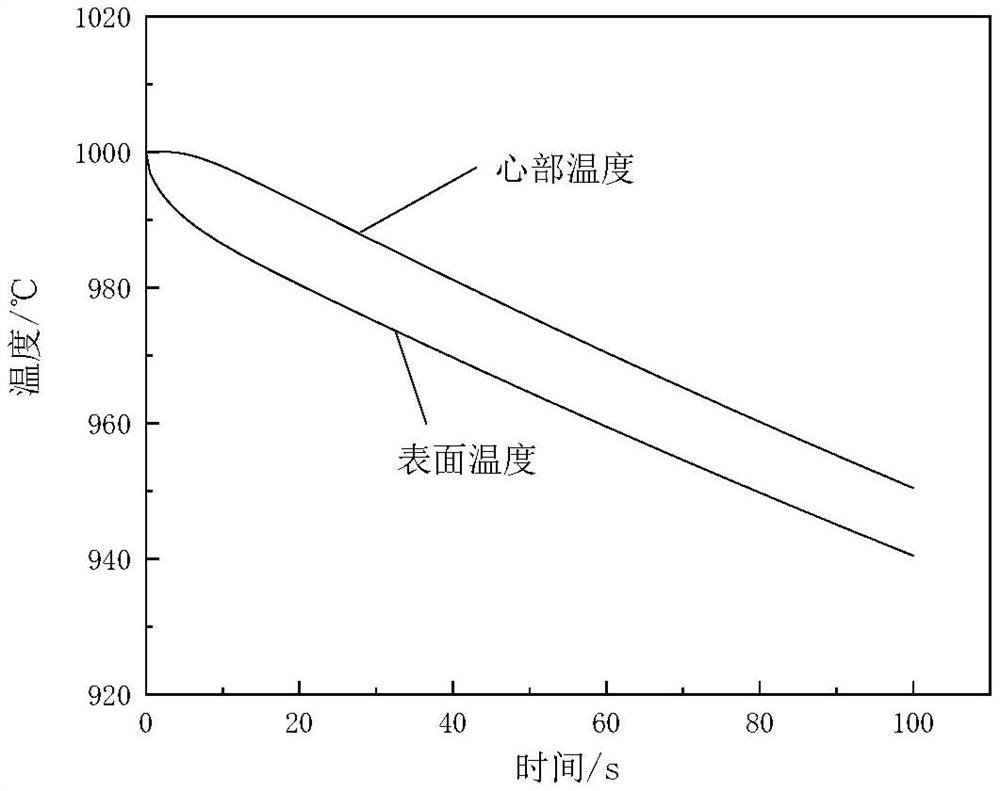

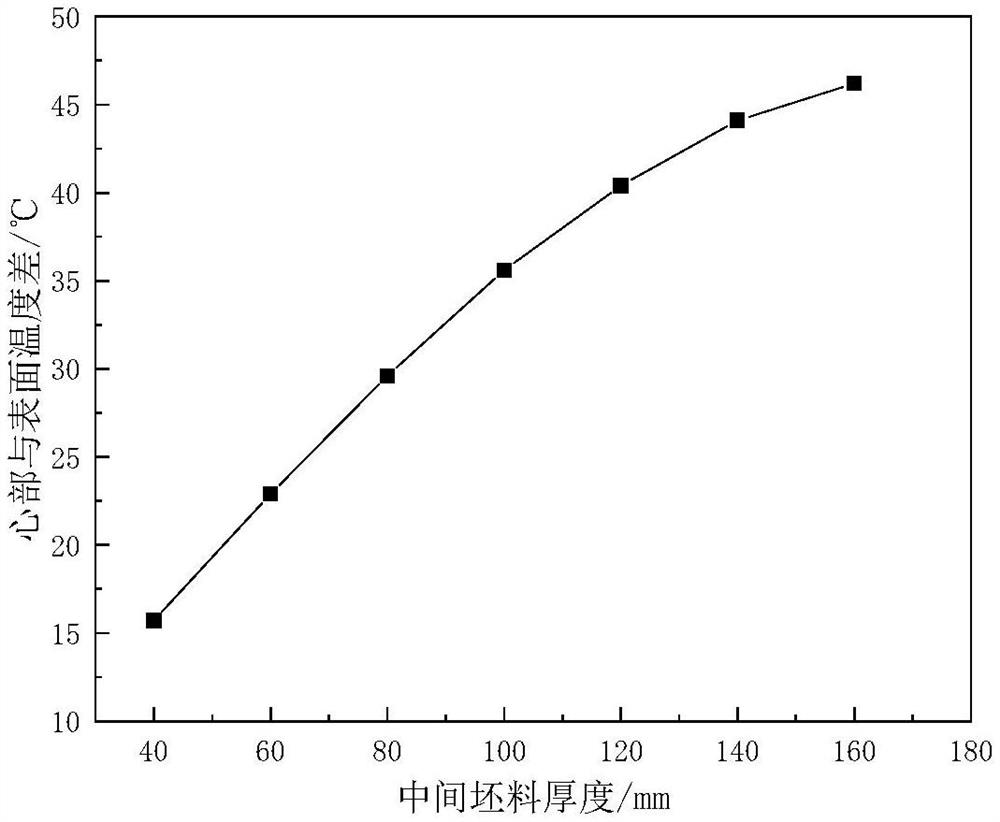

High-precision prediction method for average temperature of intermediate billet of wide and thick plate

ActiveCN114472551ATemperature Calculation Accuracy GuaranteedMeet engineering application requirementsTemperature control deviceDesign optimisation/simulationThick platePredictive methods

The invention discloses a high-precision prediction method for the average temperature of intermediate billets of wide and thick plates, and relates to the technical field of steel production. Based on a temperature partial differential equation, an implicit finite difference method is adopted to establish a temperature solving equation set of the wide and thick plates, and temperature fields in the temperature waiting process of the intermediate billets with different thicknesses are calculated; temperature distribution in the thickness direction under the condition of stable temperature is obtained, and then the difference value between the surface temperature and the average temperature is obtained; due to the fact that the mechanism model is adopted to calculate the temperature field, the temperature calculation precision can be guaranteed, meanwhile, regression processing is carried out on the calculation result, the average temperature of the steel billet can be rapidly calculated according to the surface temperature value of the steel billet, and the engineering application requirement is met.

Owner:NANJING IRON & STEEL CO LTD

Method for producing hot rolled steel coils

InactiveCN102127699BReduce dosageSimple methodProcess efficiency improvementNiobiumMaterials science

The invention relates to a method for producing hot rolled steel coils. The method comprises the following steps: 1) designing the components, pretreating molten iron, then carrying out converter smelting, carrying out nitrogen / argon changing over and carrying out tapping to obtain molten steel; 2) continuously casting the molten steel to obtain slabs, controlling the weight of the molten steel in the tundish to be 8-15t when casting of the continuous casting tundish is stopped, ensuring the liquid level to be 200-350mm; carrying out protective casting in the whole course and ensuring the insertion depth of the long nozzle to be 300-400mm; 3) heating the slabs; and 4) finally rolling and curling the heated slabs, thus obtaining the hot rolled steel coils. The method has the following beneficial effects: the TMCP (thermo-mechanical control process)+RPC (relaxation-precipitation-controlling phase transformation) rolling processes are adopted and the contents of C and Mn are substantially reduced by utilizing micro-niobium treatment, thus reducing the production cost; and the Q345R hot rolled steel coils obtained by the method have excellent plasticity and toughness, the elongation of the hot rolled steel coils is improved by more than 8%, and at the same time, the welding property of the materials is improved and good surface quality of the continuous casting slabs is ensured.

Owner:NINGBO IRON & STEEL

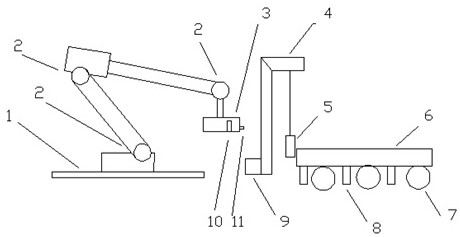

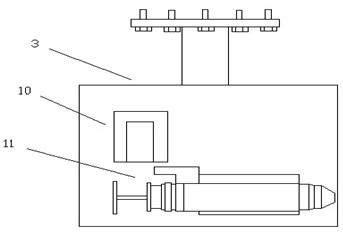

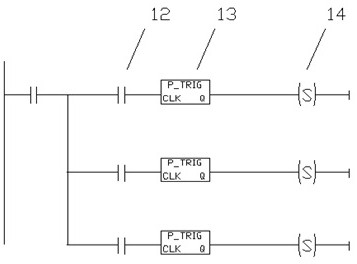

Operation method and device for billet casting and mark spraying through mechanical arm type automatic mark spraying device

PendingCN113102705ARealize continuous spray numberGuaranteed continuous spray numberRobot handSteelmaking continuous casting

The invention relates to an operation method and a device for billet casting and mark spraying through a mechanical arm type automatic mark spraying device, and belongs to the technical field of steelmaking continuous casting billet production. According to the technical scheme, by modifying a PLC program, all flow casting billet in-place manual buttons are added to a computer picture, program linkage is added, input setting of digital signals is achieved, and two schemes of a touch type automatic mode and an on-site confirmation manual mode are connected. The operation method and the device for billet casting and mark spraying through the mechanical arm type automatic mark spraying device have the beneficial effects that a manual mark spraying signal device is additionally arranged on the picture of a mechanical arm type automatic mark spraying robot, continuous mark spraying of the mark spraying robot is guaranteed under the abnormal state of equipment, the use operation rate is improved, and the mark mixing accident of take-out billets is avoided to the maximum extent.

Owner:SHIJIAZHUANG IRON & STEEL

Method for testing conductivity correction coefficients of 7-series aluminum alloys with different curvature radii

InactiveCN109444220AGuarantee the quality of inspectionReduce quality objectionsMaterial resistanceEddy currentElectrical resistivity and conductivity

The invention discloses a method for testing conductivity correction coefficients of 7-series aluminum alloys with different curvature radii, and relates to a method for testing conductivity correction coefficients with different curvature radii. The method aims to solve the problems that The Method for Determining Aluminum Alloys Conductivity Using Eddy Current in the current domestic aluminum alloy conductivity test standard GB / T 12966-2008 only specifies correction coefficients when testing a curved surface material for a 2.067-type eddy electric conductivity meter, the 2.069-type electricconductivity meter has no relevant data accumulation at present, the correction coefficient of the conductivity value of the curved surface material cannot be obtained, so that the product inspectionquality cannot be guaranteed when the method is applied to actual production detection, and the quality objection is easy to occur. The method includes the following steps: I. selecting sample materials; II. preparing samples with different curvature radii; III. testing equipment; IV. testing the conductivity; V. summarizing. The method is mainly used for testing the conductivity correction coefficients of the 7-series aluminum alloys with different curvature radii.

Owner:NORTHEAST LIGHT ALLOY CO LTD

A visual and intelligent judgment system and method for hot rolling temperature of steel coil

ActiveCN112024613BReduce human inputImprove detection efficiencyProgramme controlTemperature control deviceThermodynamicsTemperature curve

Owner:MAANSHAN IRON & STEEL CO LTD

Control method of macular rust in cold-rolled pickling line

ActiveCN106367768BReduce quality objectionsReduce the conversion rateDrying solid materials without heatSpraying apparatusHigh concentrationLow speed

The invention provides a control method for macular corrosion of a cold rolling pickling machine set. The control method comprises the following steps: first, determining possible reasons for formation of the macular corrosion, and then controlling the formation of the macular corrosion according to the possible reasons for the formation of the macular corrosion, wherein the possible reasons for the formation of the macular corrosion comprises the following seven types: the macular corrosion formed in a low-speed process of a process stage, the macular corrosion formed by over-high concentration of residual C1 on the surface of band steel, the macular corrosion formed by excessive temperature difference between a water temperature and an acid temperature in a bleaching stage, the macular corrosion formed by accidental shutdown or slow speed, the macular corrosion formed by low pressure of a squeezing roller and low temperature of a drying machine in the process stage, the macular corrosion formed by instability of voltage of an electrostatic oiler, and the macular corrosion formed by high humidity in a working field. By utilizing the control method for the macular corrosion of the cold rolling pickling machine set, the problems of great loss and the like caused by the defect of the macular corrosion of the band steel can be solved.

Owner:RIZHAO BAOHUA NEW MATERIAL CO LTD

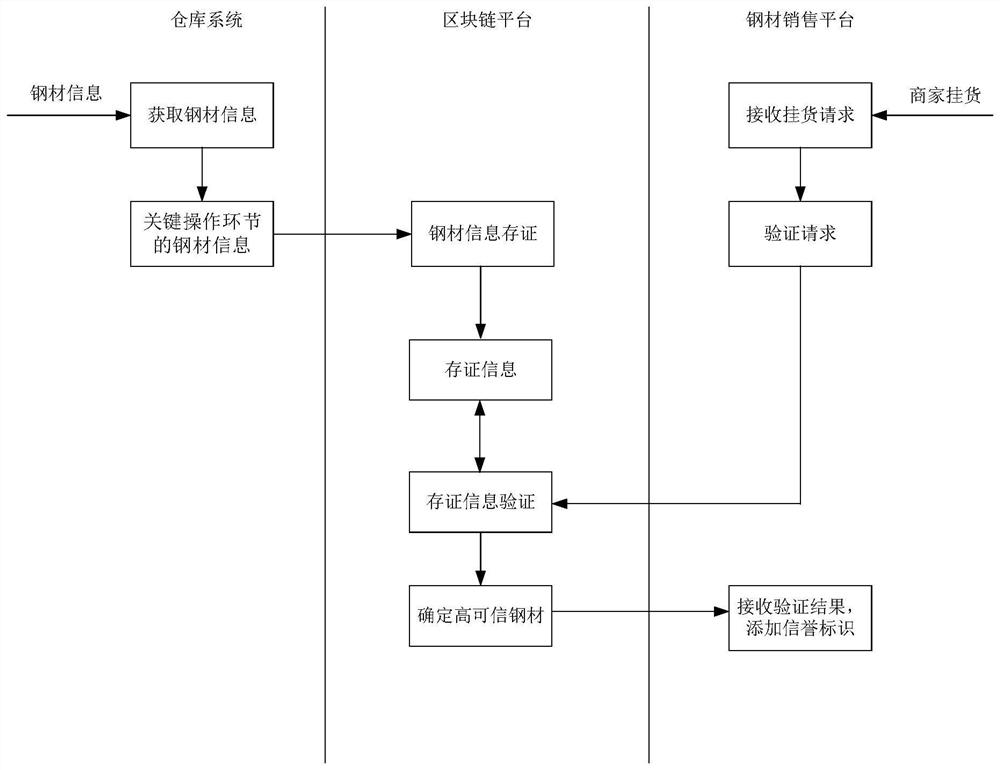

High-credibility steel hanging identification method and system based on blockchain evidence storage verification

PendingCN112488632AHighly reliableAchieve effective identificationDatabase distribution/replicationDigital data protectionResource informationFinancial transaction

The invention relates to a high-credibility steel hanging identification method and system based on blockchain evidence storage verification. The method comprises the steps that a blockchain platform,a warehouse information system and a steel sales platform are constructed and accessed to the blockchain platform; after the steel enters the warehouse, the warehouse information system acquires thesteel information of each operation link in real time, and uploads the steel information of the key operation link to the block chain platform for evidence storage to generate evidence storage information; the steel sales platform receives a merchant hanging request and sends a verification request to the blockchain platform; the block chain platform verifies the evidence storage information of the to-be-mounted steel, determines whether the to-be-mounted steel is high-credibility steel or not, generates a verification result and returns the verification result to the steel sales platform; andthe steel sales platform receives the verification result, and if the steel is high-credibility steel, a reputation identifier is added to the hung steel. Compared with the prior art, higher credit endorsement is provided for high-quality steel resources, the credibility of steel resource information is ensured, the communication cost in the transaction process is reduced, and the transaction efficiency is improved.

Owner:欧冶云商股份有限公司

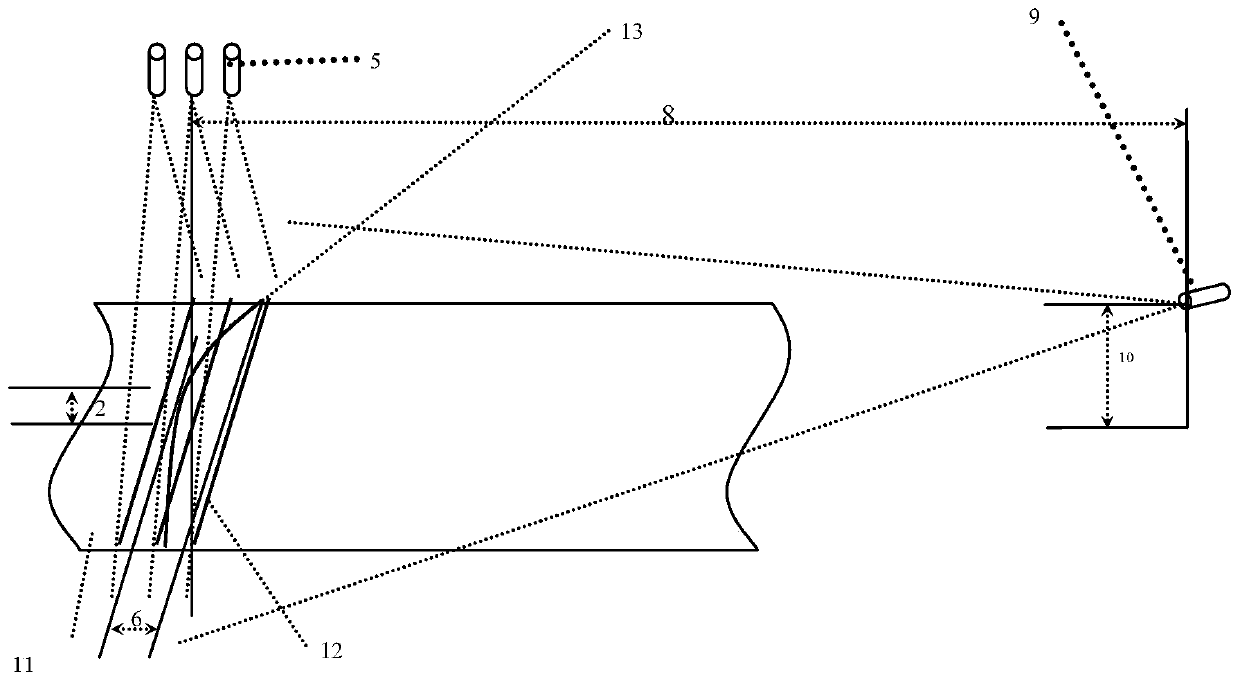

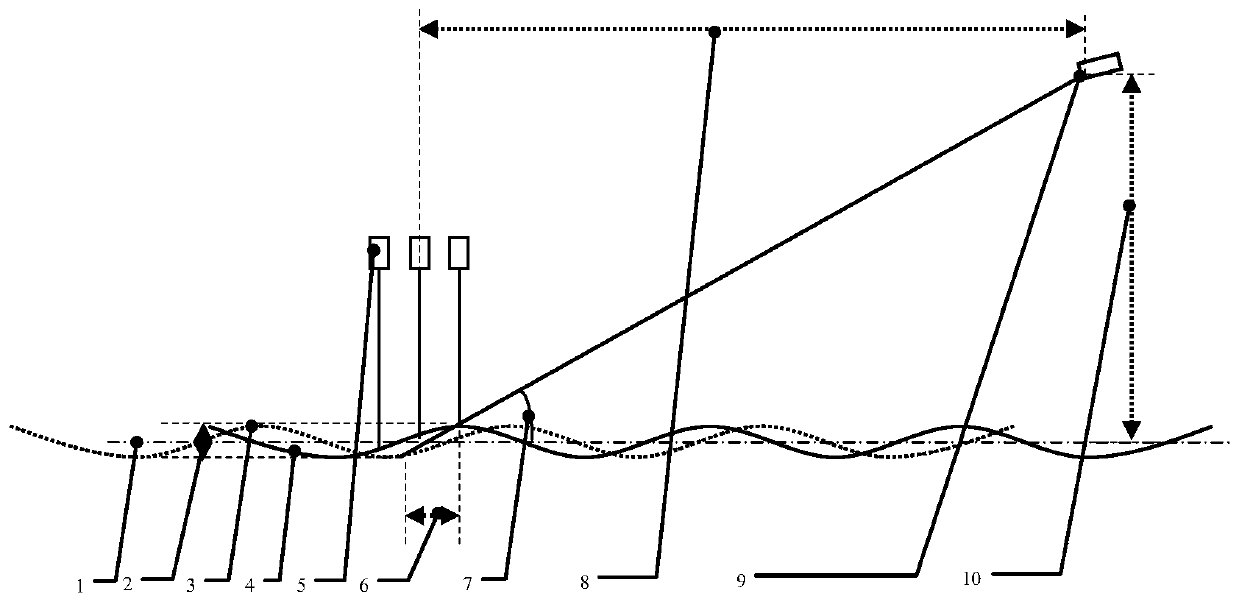

A laser flatness monitoring method and system for a hot rolling skin pass unit

ActiveCN109108096BShow Wave HeightMeet the shape quality requirementsMeasuring devicesMetal rolling arrangementsLaser transmitterWave shape

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Production process of aluminium-containing steel

InactiveCN1219099CIngredient requirements metMeet Performance StrengthElectric furnaceProcess efficiency improvementOxygenDeoxygenation

Owner:NANJING NANGANG IND DEV CO LTD

Multi purpose color coating boards, and preparation method

ActiveCN100566996CMeet different performance requirementsEasy to useSynthetic resin layered productsSpecial ornamental structuresEnvironmental resistanceEpoxy

The invention discloses a multi-purpose color-coated board and a preparation method thereof, which comprises a front coating, a substrate, and a back coating. The film-forming resin of the back coating is epoxy resin with a purity of 90-99%. Compared with the existing technology, the invention combines the advantages of the traditional single-coat and double-coat system color-coated boards, meets the different performance requirements of users when processing corrugated boards and sandwich boards, and provides users with the advantages of use, cost control, and inventory. It provides convenience and greatly improves the market competitiveness of color-coated board products. Simultaneously, by replacing common chromium strontium yellow pigment with titanium-nickel pigment in the coating, while improving the decoration of the present invention, also strengthened the corrosion resistance of the present invention, reduced the environmental pollution of hexavalent chromium, for The foundation has been laid for the further development of environmentally friendly products.

Owner:MAANSHAN IRON & STEEL CO LTD

Visual and intelligent system and method for determining hot rolling temperature of steel coil

ActiveCN112024613AReduce human inputImprove detection efficiencyProgramme controlTemperature control deviceTemperature curveControl engineering

The invention discloses a visual and intelligent system and method for determining hot rolling temperature of a steel coil, and belongs to the technical field of hot rolling. The system for determining the hot rolling temperature comprises a hot rolling first-stage system, a hot rolling second-stage system, a temperature detection device, an encoder, a data acquisition machine and a QMS managementapplication platform. According to the system, through input of the order information of a relevant steel coil on the QMS management application platform, Differentiation configuration of evaluationtolerances is performed in a server of the QMS management application platform according to the steel coil output event information, and the steel coil hot rolling temperature curve data collected onsite is transmitted to the QMS management application platform; and through development of a set function is developed and formulation of a quality factor on the QMS management application platform, the hot rolling temperature curve is analyzed and processed. Whether the hot rolling temperature of the steel coil to be detected is qualified or not is automatically judged, so that manual query workcan be greatly reduced, and the working efficiency and judgment accuracy are improved.

Owner:MAANSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com