Optimal control system of shape and thickness of steel plate

An optimization control and steel plate technology, which is applied in the direction of contour control, rolling force/roll gap control, etc., can solve problems such as excessive unevenness, failure to meet customer requirements, small broken waves of thick steel plates, etc., to achieve plate shape improvement and reduction Leveling and cold straightening process, the effect of saving process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

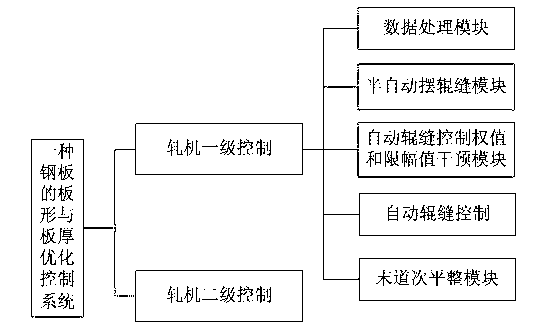

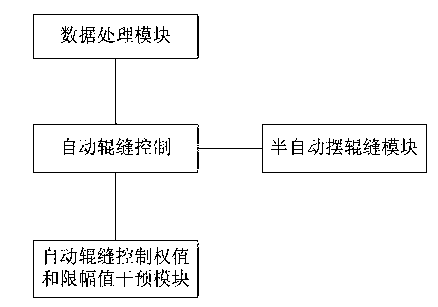

[0016] by attaching figure 1 with figure 2 It can be seen that the profile and thickness optimization control system of a steel plate in this program includes the primary control of the rolling mill and the secondary control of the rolling mill that provides rolling tables for the primary control of the rolling mill. The primary control of the rolling mill includes automatic Roll gap control and a data processing module connected with the automatic roll gap control, and the first-level control of the rolling mill also includes a final pass leveling module, a semi-automatic swing roll gap module connected with the automatic roll gap control and an automatic Roll gap control weight and limit value intervention module; where:

[0017] The final pass leveling mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com