Multi purpose color coating boards, and preparation method

A color-coated plate, multi-purpose technology, applied in the direction of chemical instruments and methods, coatings, special decorative structures, etc., can solve problems such as difficult to ensure processing adhesion, poor decorative performance of coatings, and uneven adhesion performance , to achieve the effect of improving decoration, reducing production cost and reducing quality objections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

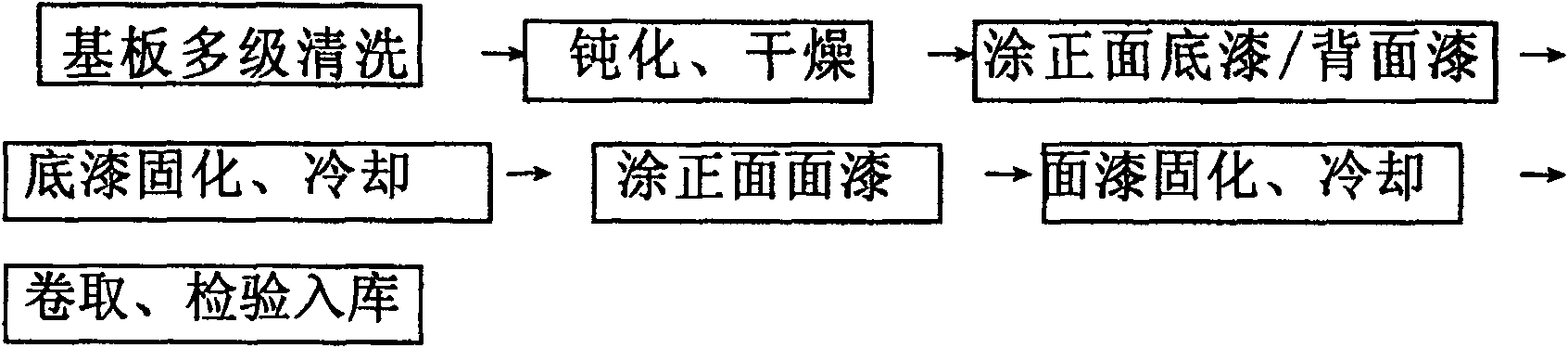

Method used

Image

Examples

Embodiment 1

[0027] The substrate is Masteel self-heating galvanized sheet; the passivation solution is Bonderite 1402W, produced by Henkel Surface Technology Co., Ltd.; the front primer is polyurethane resin, produced by Shanghai Zhenhua Paint Factory; Ester, produced by Shanghai Zhenhua Paint Factory; the back primer is pure epoxy resin paint, produced by Shanghai Zhenhua Paint Factory, the resin purity is 90-92%, the pigment used is chromium strontium yellow pigment, produced by Shanghai Zhenhua Paint Factory Produced by Huazao Paint Factory.

[0028] Clean and passivate the hot-dip galvanized substrate according to the conventional process requirements, the passivation solution concentration is 20%, adjust the passivation treatment roll speed and pressure, so that the thickness of the passivation film is 20-25mg / m 2 , apply the front primer and back paint, the thickness of the back coating is controlled at 7-9μm, bake at 180-200°C for 25s, cool, apply the front top coat, bake, cool, co...

Embodiment 2

[0029] Embodiment 2: except that the back primer is pure epoxy resin paint, produced by Shanghai Zhenhua Paint Factory, and its purity is 95-98%, all the other are identical with embodiment 1.

Embodiment 3

[0030] Embodiment 3: except the back primer is pure epoxy resin, produced by Shanghai Zhenhua Paint Factory, its purity is 98-99%, all the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com