High-precision prediction method for average temperature of intermediate billet of wide and thick plate

A technology of average temperature and prediction method, applied in temperature control, design optimization/simulation, computer-aided design, etc., can solve the problem that the preset roll gap deviates from the thickness control benchmark, the force-energy model deviates from the actual value, and the finished product rolling cannot be completed and other problems to achieve the effect of improving prediction accuracy, increasing the hit rate of final rolling, and reducing quality objections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] A high-precision prediction method for the average temperature of a wide-thick slab intermediate blank provided in this embodiment includes the following steps:

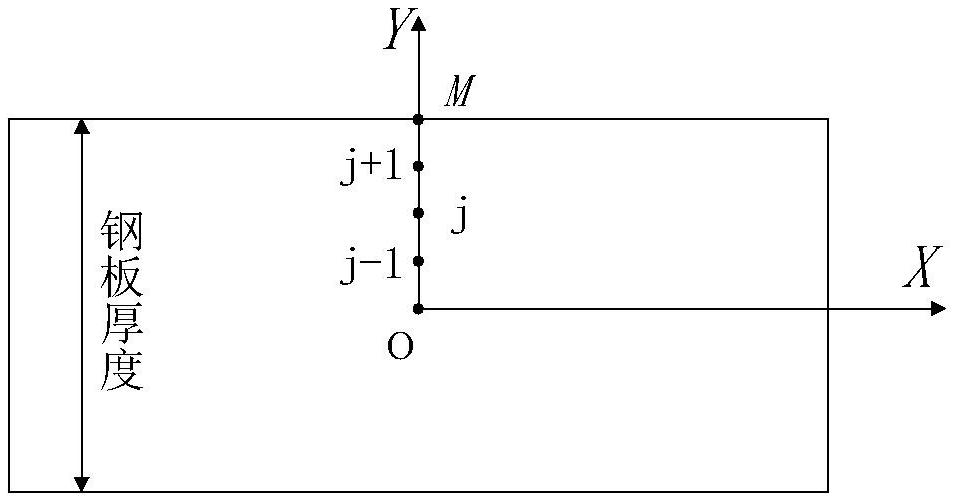

[0048] (1) The implicit finite difference method is used to solve the temperature field

[0049] For the temperature drop process of the intermediate slab of wide and thick slabs, the heat dissipation in the length and width directions is ignored, and the heat transfer process is regarded as a one-dimensional heat transfer process along the thickness direction of the billet, and the heat conduction differential equation without considering the internal heat source is expressed by formula ①

[0050]

[0051] In the formula, α=k / (ρc) is the temperature conductivity coefficient, ρ is the material density, c is the specific heat, and k is the thermal conductivity coefficient;

[0052] For a given heat transfer coefficient and the temperature boundary condition of the surrounding medium, the form is:

[0053] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com