Anti-cracking soil stabilizer and using method

A soil curing agent and anti-cracking technology, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problem of easy cracking of solid soil curing agent, and achieve the effect of preventing cracks and environmental protection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment one: anti-cracking soil curing agent of the present invention

[0026] The soil solidifying agent of the present invention includes slag powder, desulfurized gypsum, β-type hemihydrate gypsum, fly ash, construction waste powder, potassium salt or ammonium salt and an activator. The slag powder used is the molten slag with calcium aluminosilicate as the main component obtained when the ironworks smelt pig iron in the blast furnace.

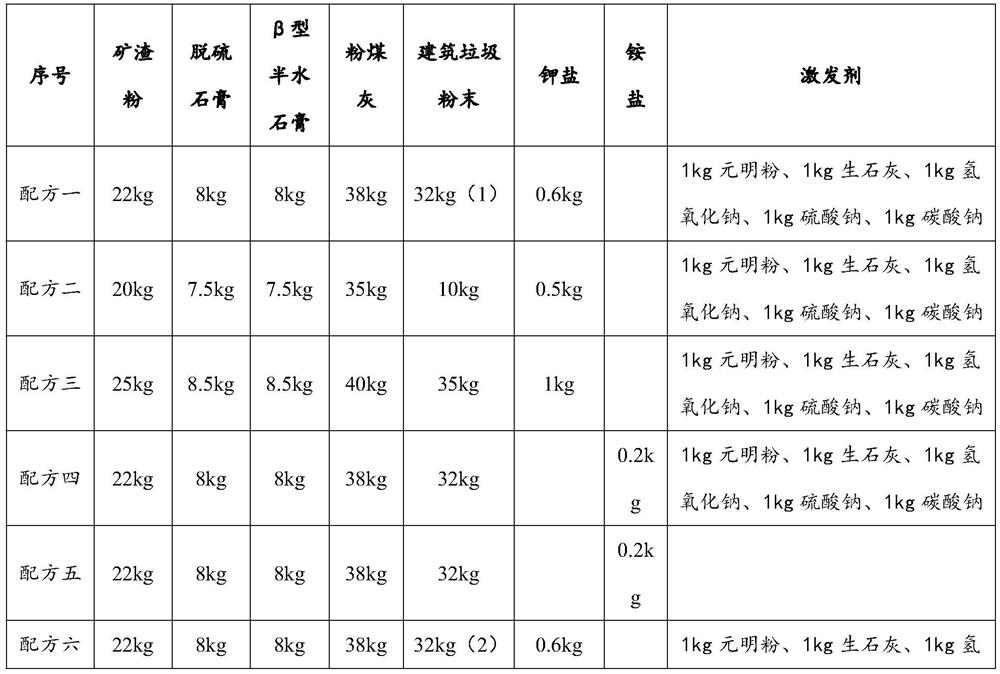

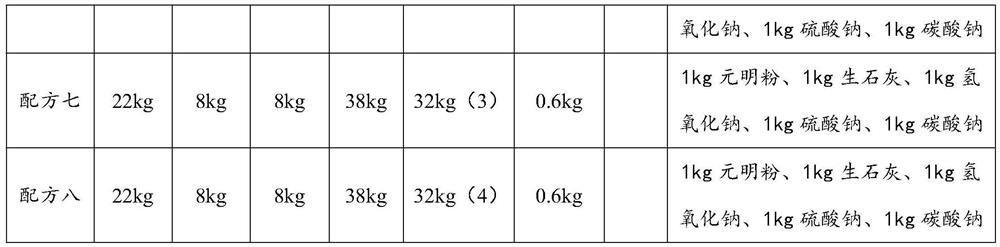

[0027] Specifically, the formula used in this embodiment is as follows:

[0028]

[0029]

[0030] In the above formula, the construction waste powder used is different in formulas one, six, seven, and eight. The construction waste powder (1) in formula one is 12kg cement fine powder and 15kg red brick fine powder. The construction waste powder (2) in formula six is 10kg cement fine powder and 10kg red brick fine powder. The construction waste powder (3) in formula seven is 15kg cement fine powder and 20kg red brick fine...

Embodiment 2

[0031] Embodiment two: the using method of anti-cracking soil solidifying agent of the present invention

[0032] The invention provides a method for using an anti-cracking soil curing agent, comprising the steps of:

[0033] (1) Mix the raw materials according to the ratio and use a ball mill to fully grind and mix them into a curing agent product with a fineness of about 400 mesh.

[0034] (2) Measure the water content of the target soil to be used, and determine the optimal water content according to the soil water content, so that the cuttings are easy to mix and not too thin to solidify or too dry to mix evenly.

[0035] (3) After the curing agent product in step (1) is mixed with water, it is mixed with soil, and then the mixture is repeatedly kneaded with an excavator to make the curing agent fully contact with the mixed soil.

Embodiment 3

[0036] Embodiment 3: performance test of anti-cracking soil stabilizer

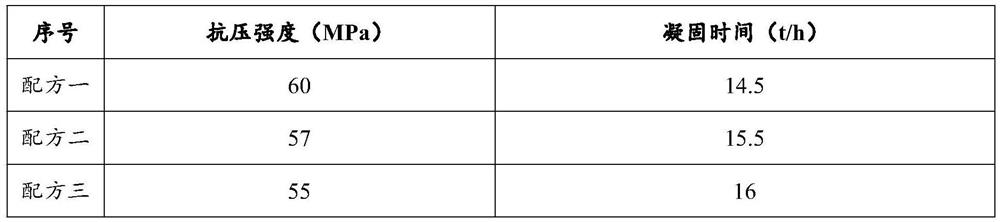

[0037] When detecting the performance of the anti-cracking soil solidifying agent of the present invention, the strength of the solidified type is detected with reference to the technical index of the cement type JX-GH. The test results are as follows:

[0038]

[0039]

[0040] It can be seen from formulas 1, 6, 7 and 8 of the above examples that the composition of construction powder has a certain influence on the compressive strength and setting time. From 1 and 4, it can be seen that potassium salt and ammonium salt have corresponding effects , can make the final compressive strength and solidification time meet the requirements, compared with potassium salt is better. This may be because the potassium salt has a clear relationship with the influence of montmorillonite in the soil, so that the amount added is far greater than the corresponding demand of montmorillonite to avoid the influence of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com