High-performance low-carbon microalloy steel SEW (hot stretch-reducing electric welding) expansion casing and manufacturing method thereof

A technology for expanding casing and alloy steel, applied in casing, manufacturing tools, drill pipes, etc., can solve the problems of easy formation of gray spots, high cost of raw materials, failure and brittleness of welds, etc., and achieve excellent uniform deformation ability, The effect of uniform mechanical properties and optimized weld structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Manufacturing method of Φ139.7×7.72mm 80 steel grade SEW expansion sleeve.

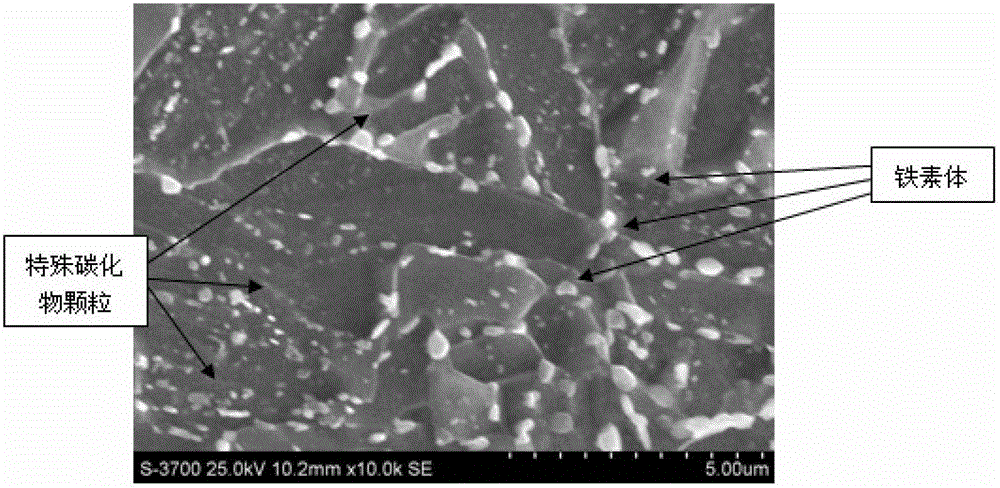

[0028] TMCP hot-rolled coil raw material composition (wt.%): C 0.24, Si 0.28, Mn 1.39, P 0.008, S 0.003, Nb+V+Ti 0.31 in total, and the rest is Fe and unavoidable impurities.

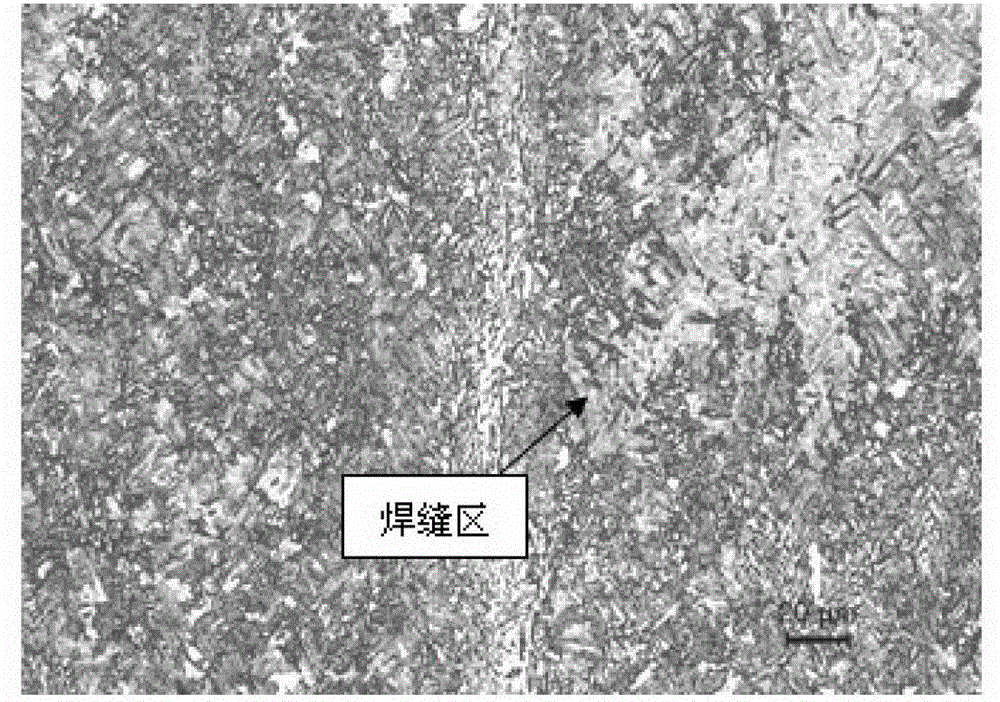

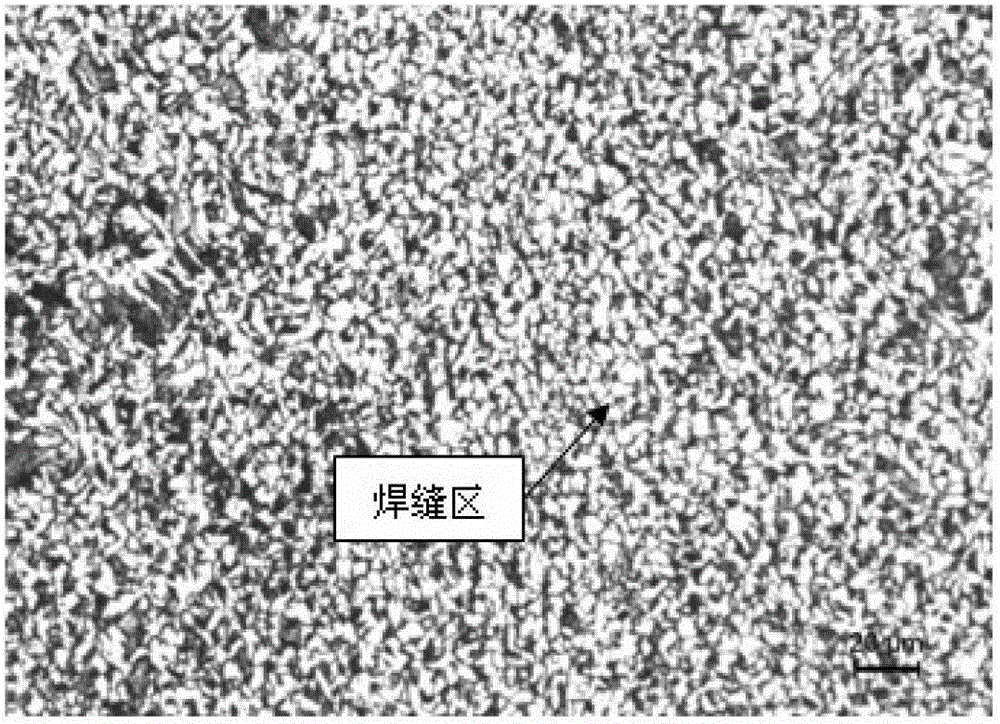

[0029]First, prepare the HFW welded pipe: the TMCP hot-rolled coil with the above-mentioned chemical composition with a wall thickness deviation of -0.20~+0.20mm and high dimensional accuracy is subjected to strip slitting, edge milling, FFX forming and HFW welding to adjust the forming process (opening angle 5°, extrusion amount 3.0mm), control the welding parameters (welding power 540KW, welding speed 18m / min) to weld a straight seam welded pipe with a specification of Φ193.7×7.34mm, and burr the inner and outer welds immediately after welding For trimming, the residual height of the inner burr scraping groove and the outer burr is ≤0.25mm, so that the weld bead and the inner and outer surfaces of the pipe a...

Embodiment 2

[0034] Embodiment 2: Manufacturing method of Φ108×6.35mm 80 steel grade SEW expansion sleeve.

[0035] TMCP hot-rolled coil raw material composition (wt.%): C 0.22, Si 0.18, Mn 1.28, P 0.010, S 0.001, Nb+V+Ti 0.24 in total, the rest is Fe and unavoidable impurities.

[0036] First, prepare the HFW welded pipe: the TMCP hot-rolled coil with the above-mentioned chemical composition with a wall thickness deviation of -0.20~+0.20mm and high dimensional accuracy is subjected to strip slitting, edge milling, FFX forming and HFW welding to adjust the forming process (opening angle 3°, extrusion amount 2.5mm), control the welding parameters (welding power 510KW, welding speed 24m / min) to weld a straight seam welded pipe with a specification of Φ193.7×5.75mm, and burr the inner and outer welds immediately after welding For trimming, the residual height of the inner burr scraping groove and the outer burr is ≤0.25mm, so that the weld bead and the inner and outer surfaces of the pipe are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com