Movable device displacement measurement method as well as rough mill and gate footstep shear using same

A technology of movable devices and measuring methods, which is applied in the direction of shearing devices, length measuring devices, and accessories of shearing machines, etc., can solve the problems of closed-loop control of measurement results, difficulty in eliminating gaps, inaccurate measurement, etc., and reduce camber phenomenon , Overcome the position measurement error and improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

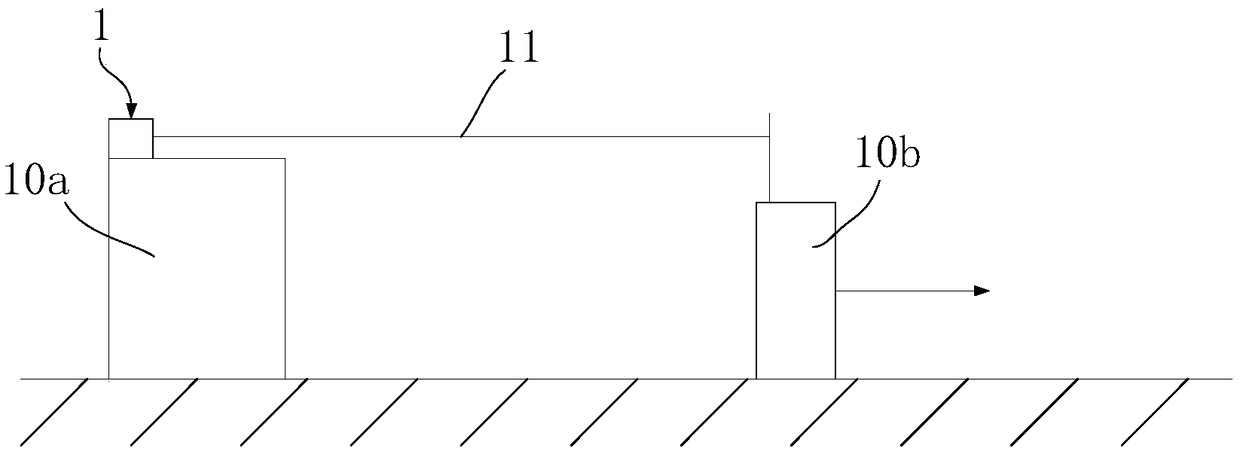

Embodiment 1

[0023] Embodiment 1. In this embodiment, the position of the front side guide plate of the rough rolling mill of a medium plate factory is measured in real time, and the maximum width of the outer contour of the clamped steel plate is calculated. The front side guide plate of the rough rolling mill is located in front of the four-high reversible rolling mill and above the tapered work roll table in front of the machine, and is used to cooperate with the turning of the rolled piece, measure the width, push and clamp the rolled piece, and make it centered on the rolling center line to ensure smooth entry and exit of the rolled piece rolling mill. It is a mechanical speed-increasing rack-and-pinion side guide plate driven by a hydraulic cylinder. It is mainly composed of main transmission box, return transmission box, push plate, side guide box, speed measuring device, pull rod device, hydraulic pressure, dry oil piping and other components. The main transmission box is composed...

Embodiment 2

[0025] Embodiment 2, the application of this embodiment to the measurement of the width of steel plate sheared by the 3# guillotine in a medium plate factory. There are 4 guillotine scissors in the medium plate factory to cut the head, tail, width and edge of the steel plate respectively. The 3# shear is for the final width sizing. It is necessary to ensure that the width of the finished steel plate meets the order requirements. The original system used the installation scale to measure the width. As the value of the scale changes with the movement of the push head, the operator determines the plate width through the indicated value of the scale to cut the width. The error is 6mm. Different operating tools have different reading deviations. Width has a greater influence, which affects the cutting quality.

[0026] After applying the measurement method described in the present invention, the wire-drawing encoder is installed on the fixed base of the edge pushing machine, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com