Rolling process of Ti-containing low alloy steel

A low-alloy steel and process technology, which is applied in the field of Ti-containing low-alloy steel rolling process, can solve problems such as difficult plate shape control, cracking of coiled pipes, and large thermal stress, and achieves small performance fluctuation range, reduced maintenance costs, and good performance. The effect of welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

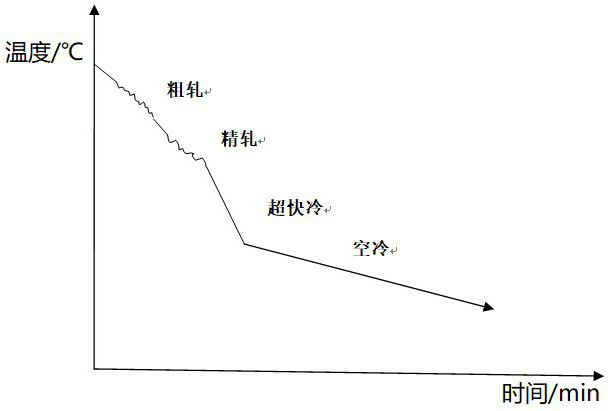

[0041] The rolling process includes the following steps:

[0042] 1. The steelmaking process produces suitable slabs;

[0043] 2. The slab in step 1 is directly heated at high temperature, and the high temperature heating is divided into three sections, the heating section is 1260°C, the soaking section is 1240°C, the furnace core temperature is 1240°C, the heating rate is 6min / cm, and the total time in the furnace is 3h;

[0044] 3. Rough rolling is carried out on the slab heated at high temperature in step 2. The rough rolling is rapid rolling at high temperature and high pressure. The maximum pass reduction is selected for the formulation of the reduction program, and the maximum pass reduction rate reaches more than 20%, and the rolling is started. The temperature is 1150°C, and the final rolling temperature is 1080°C;

[0045] 4. Finish rolling the slab after the rough rolling in step 3, the cumulative reduction rate of the finishing rolling is greater than 60%, the redu...

Embodiment 2

[0050] The rolling process includes the following steps:

[0051] 1. The steelmaking process produces suitable slabs;

[0052] 2. The slab in step 1 is directly heated at high temperature. The high temperature heating is divided into three sections. The heating section is 1300°C, the soaking section is 1280°C, the furnace core temperature is 1260°C, the heating speed is 8min / cm, and the total time in the furnace is 3.8h ;

[0053] 3. Rough rolling is carried out on the slab heated at high temperature in step 2. The rough rolling is rapid rolling at high temperature and high pressure. The maximum pass reduction is selected for the formulation of the reduction program, and the maximum pass reduction rate reaches more than 20%, and the rolling is started. The temperature is 1180°C, and the final rolling temperature is 1150°C;

[0054] 4. Finish rolling the slab after the rough rolling in step 3, the cumulative reduction rate of the finishing rolling is greater than 60%, the red...

Embodiment 3

[0059] The rolling process includes the following steps:

[0060] 1. The steelmaking process produces suitable slabs;

[0061] 2. The slab in step 1 is directly heated at high temperature. The high temperature heating is divided into three sections, the heating section is 1280°C, the soaking section is 1260°C, the furnace core temperature is 1250°C, the heating rate is 7min / cm, and the total time in the furnace is 5h;

[0062] 3. Rough rolling is carried out on the slab heated at high temperature in step 2. The rough rolling is rapid rolling at high temperature and high pressure. The maximum pass reduction is selected for the formulation of the reduction program, and the maximum pass reduction rate reaches more than 20%, and the rolling is started. The temperature is 1170°C, and the final rolling temperature is 1100°C;

[0063] 4. Finish rolling the slab after the rough rolling in step 3, the cumulative reduction rate of the finishing rolling is greater than 60%, the reductio...

PUM

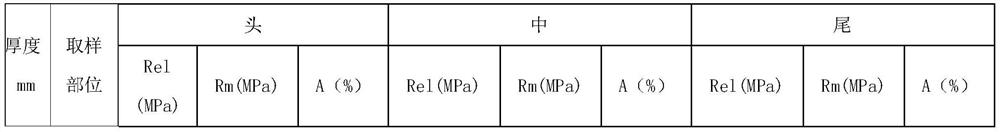

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com