Liquid mixing device and mixing method

A technology of liquid mixing device and mixing chamber, which is applied in chemical instruments and methods, various fluid ratio control, instruments, etc., can solve problems such as inconvenience of rapid detection, interference, and influence on the accuracy of results, so as to simplify the structure, realize sealing, Achieve accurate control of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

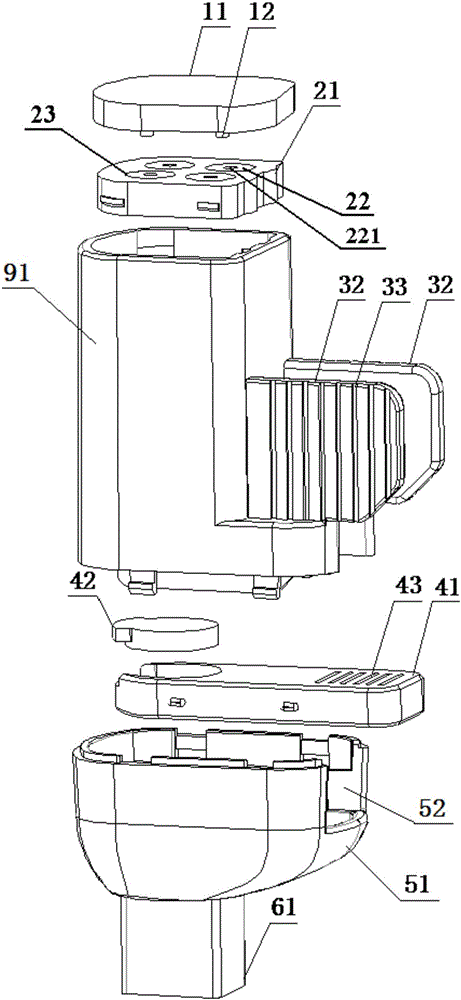

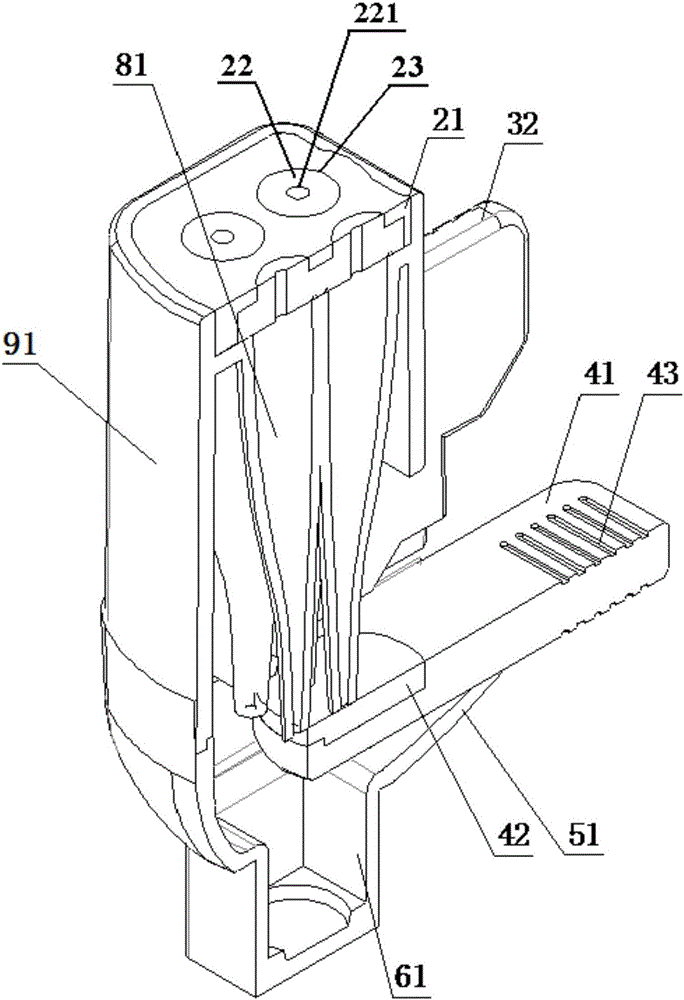

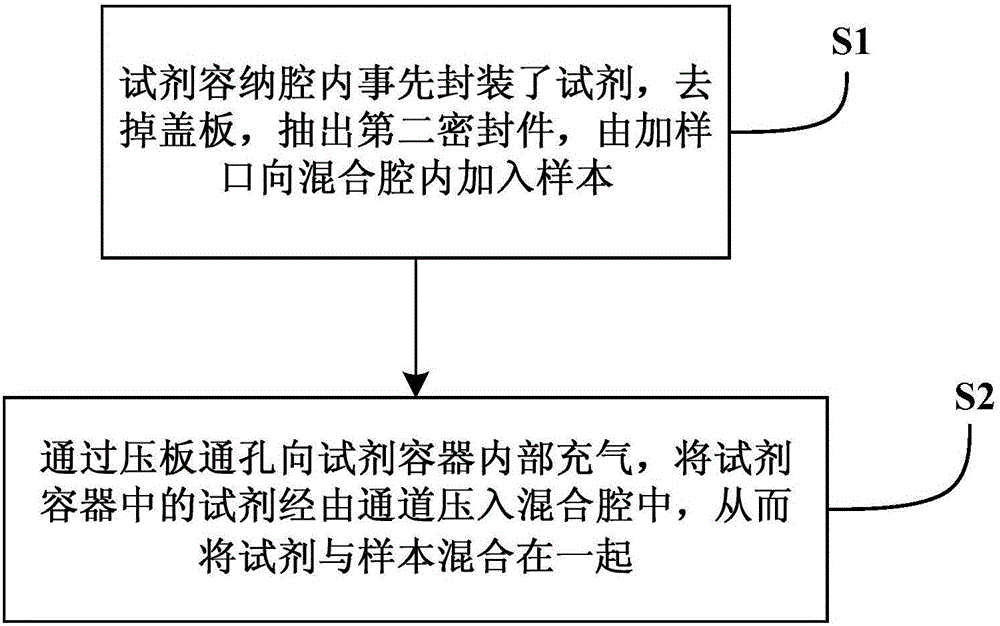

[0027] This embodiment discloses a liquid mixing device, such as figure 1 As shown, it includes a reagent containing chamber 91 and a mixing chamber 61. The reagent containing chamber 91 and the mixing chamber 61 are connected by a narrow channel 51 from top to bottom. The top and bottom of the channel 51 are open, and the side walls of the channel 51 A sample injection port 52 is provided on the top to facilitate adding samples into the mixing chamber 61 . The side wall of the reagent containing chamber 91 is provided with a reagent containing chamber handle 32 that is convenient to hold, and the outer surface of the reagent containing chamber handle 32 is provided with at least two anti-slip first protrusions or first grooves 33 to increase the grip of the hand. when the friction force. Inside the reagent containing chamber 91 are provided four reagent containers 81 that shrink from top to bottom, such as figure 2 As shown, the top and bottom of the reagent container 81 a...

Embodiment 2

[0033] This embodiment discloses a liquid mixing device, which includes a reagent containing chamber and a mixing chamber, the mixing chamber is made of a material suitable for detecting light transmission, and the reagent containing chamber and the mixing chamber are connected by a narrow channel from top to bottom , the top and bottom of the channel are both open, and the side wall of the channel is provided with a sample inlet, which is convenient for adding samples into the mixing chamber. There are four reagent containers inside the reagent containing chamber. The top and bottom of the reagent containers are both open. The angle between the line connecting the center of the top opening of the reagent container and the center of the bottom opening of the reagent container and the vertical direction is greater than zero. Among the four reagent containers The connecting line between the top opening centers of two adjacent reagent containers, the offline line between the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com