Electric current sensor

A technology of current sensor and current path, applied in the direction of measuring device, voltage/current isolation, instrument, etc., can solve the problem of inability to detect current correctly, achieve the effect of suppressing malfunction and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

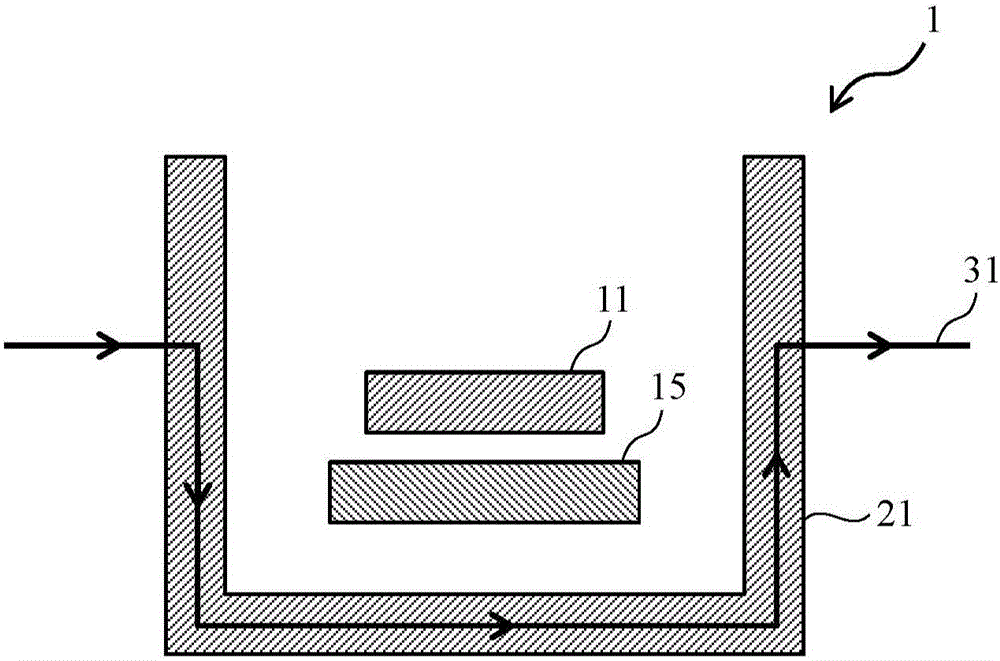

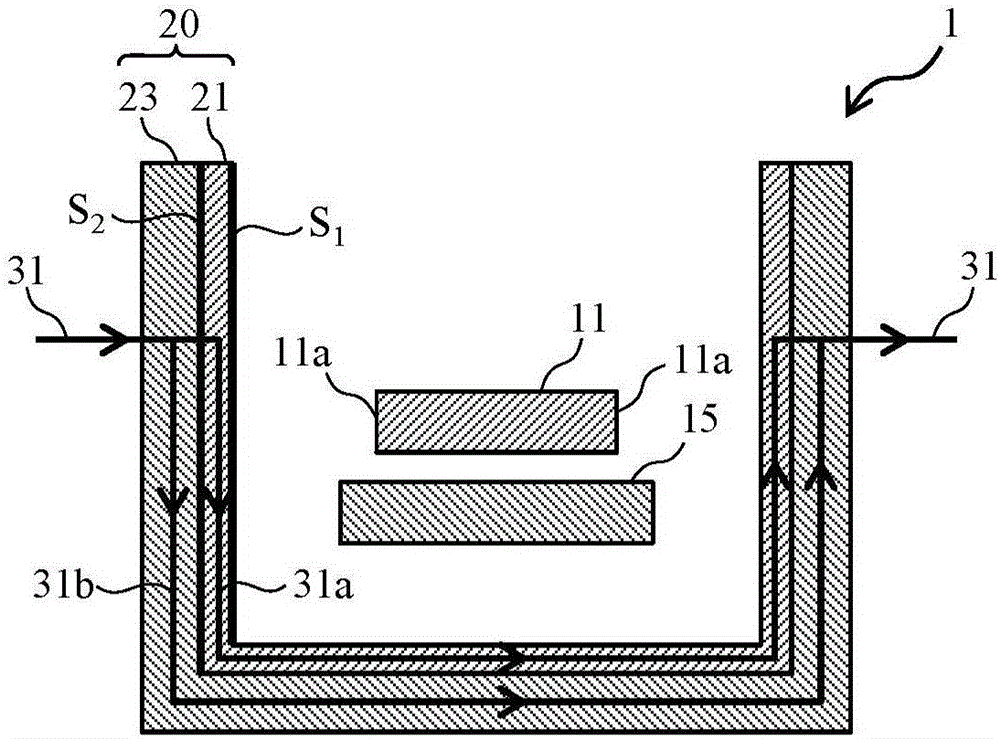

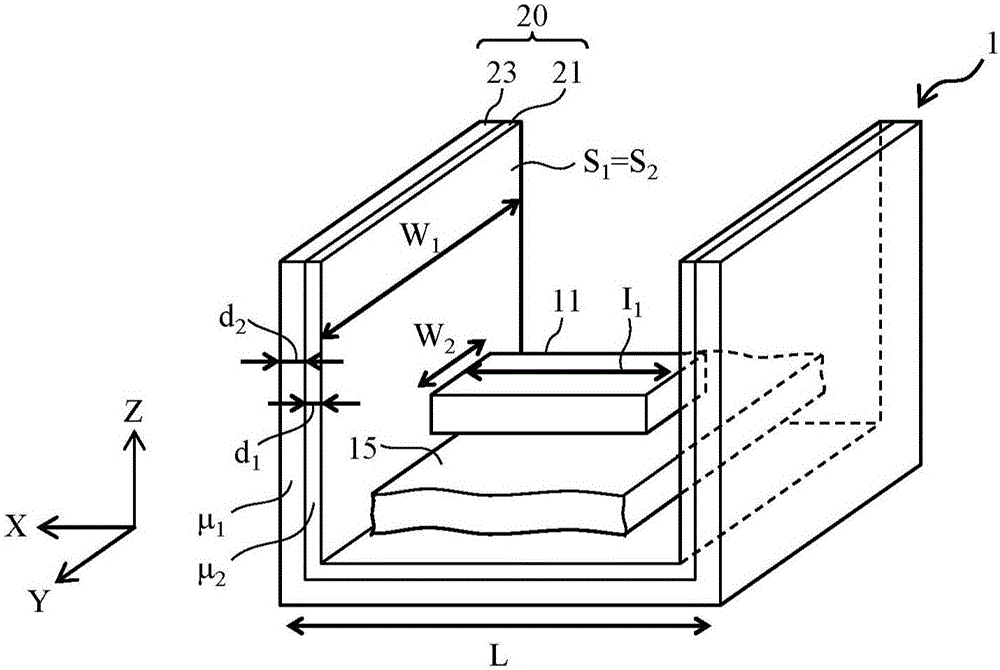

[0044] FIG. 2( a ) is a cross-sectional view showing an example of the configuration of the current sensor device according to the first embodiment of the present invention. Fig. 2(b) is a perspective view of the current sensor device shown in Fig. 2(a). Hereinafter, description will be made with reference to the x, y, and z axes defined in each figure.

[0045] As shown in FIG. 2(a) and FIG. 2(b), the current sensor device 1 of this embodiment includes, for example, a magnetic detection element (hereinafter also referred to as IC) 11 such as a Hall element. The current path extending in the y-axis direction, that is, the bus 15 . As the magnetic detection element 11 , for example, any one of a Hall element, a magnetoresistive element, and a Hall IC (IC: Integrated Circuit) combining a Hall element and an amplifier circuit can be used. As the magnetoresistance element, an anisotropic magnetoresistance element AMR, a gigantic magnetoresistance element GMR, a tunnel magnetores...

Embodiment 1

[0056] In Figure 2(a), it is possible to have the first relative permeability μ 1 The first magnetic shielding material, for example, becomes the magnetic permeable alloy PC material, so that it has the second relative magnetic permeability μ 2 The second magnetic shielding material is, for example, ferrite. The relative magnetic permeability of the magnetic permeable alloy PC material exceeds 5000, and the relative magnetic permeability of the ferrite is about 2000. In comparison, the former is more expensive. The relative magnetic permeability of the magnetic permeable alloy PC material with a thickness of 0.1mm is tens of thousands to hundreds of thousands, and the relative magnetic permeability of the magnetic permeable alloy PB material with a thickness of 0.1mm is 10,000 to 20,000, which is about 3,000 in 0.35mm. Therefore, the layer thickness of the magnetic permeable alloy is made as thin as possible, and the correspondingly reduced magnetic shielding effect is compe...

no. 2 Embodiment approach

[0091] Next, a second embodiment of the present invention will be described. FIG. 7( a ) is a cross-sectional view showing a configuration example of the current sensor device of the present embodiment. FIG. 7( b ) is a cross-sectional view showing a current sensor device according to a modified example of FIG. 7( a ). The difference from the first embodiment is that the second magnetic shield portion 23a having the second relative magnetic permeability is formed of a composite material of a magnetic material and a non-magnetic material such as a resin material. Although the effects related to the magnetic shielding produced by this structure are the same as those of the first embodiment, there is an advantage that by using an inexpensive composite material of a magnetic material and a non-magnetic material such as a resin material, it is different from that of the first embodiment. than can increase the cost reduction effect. As shown in FIG. 7(b), the second magnetic shiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com