Etching resist composition and dry film

A technology of composition and resist, which is applied in the direction of optics, optomechanical equipment, instruments, etc., and can solve problems such as inability to obtain patterns and penetration of etching solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

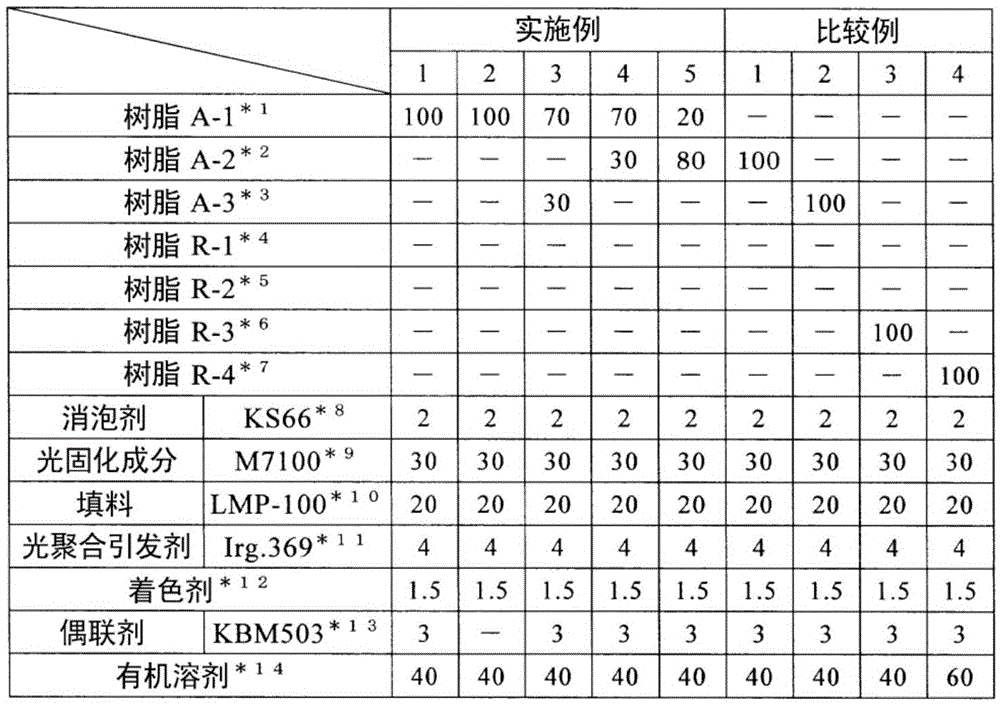

[0086] Hereinafter, although an Example and a comparative example are shown and this invention is concretely demonstrated, this invention is not limited to a following example. In addition, below, "part" and "%" are mass standards unless otherwise specified.

[0087] (Alkali-soluble resin having a biphenyl structure: Resin A-1)

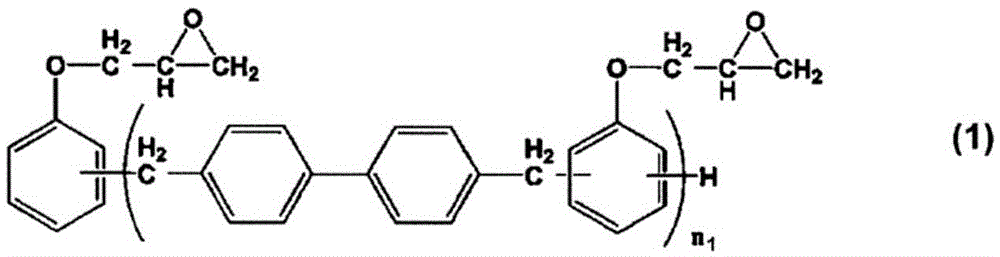

[0088] Drop into the epoxy resin (NC-3000P that Nippon Kayaku Co., Ltd. manufactures, epoxy equivalent 286, softening point 67 ℃, n is 2.24.) represented by above-mentioned general formula (1). 2860g (10 equivalents), acrylic acid 720.6g ( 10 equivalents), methyl hydroquinone 5.5g, carbitol acetate 1349.6g and solvent naphtha 578.4g, heated and stirred at 90°C to dissolve the reaction mixture. Next, the reaction solution was cooled to 60°C, 16.5 g of triphenylphosphine was added, heated to 98°C, and the reaction was carried out for about 32 hours. After the acid value (mgKOH / g) became 3.0 or less, it was cooled to obtain an epoxy acrylate resin (a-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com