Leather surface spraying system

A surface spraying and leather technology, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc., can solve the problems of high cost and low utilization rate of color paste, so as to ensure smoothness, reduce cost, and prevent failure. coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

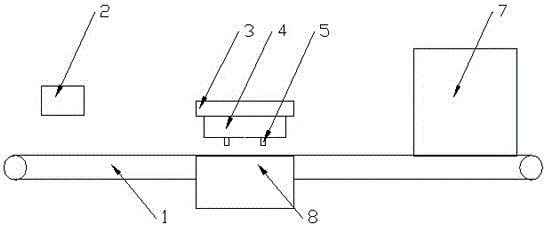

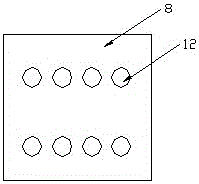

[0028] Such as figure 1 A leather surface spraying system shown includes a conveying unit, which is a conveyor belt 1 extending along the material conveying direction, and a scanning unit and a spraying unit are sequentially distributed on the conveying belt 1 along the conveying direction of the conveying belt And the drying unit, and a vacuum adsorption mechanism is installed under the spraying unit.

[0029] The scanning unit is arranged at the feeding port end of the conveyor belt 1 and includes a camera 2 installed above the conveyor belt for scanning the outer contour of the passing leather.

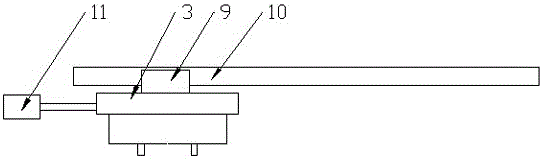

[0030] The spraying unit includes a nozzle bearing seat 3. A spray chamber 4 is installed at the lower end of the nozzle bearing seat 3. Color paste is installed in the spray c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com