Numerically-controlled machine tool feed system speed regulation method based on power prediction

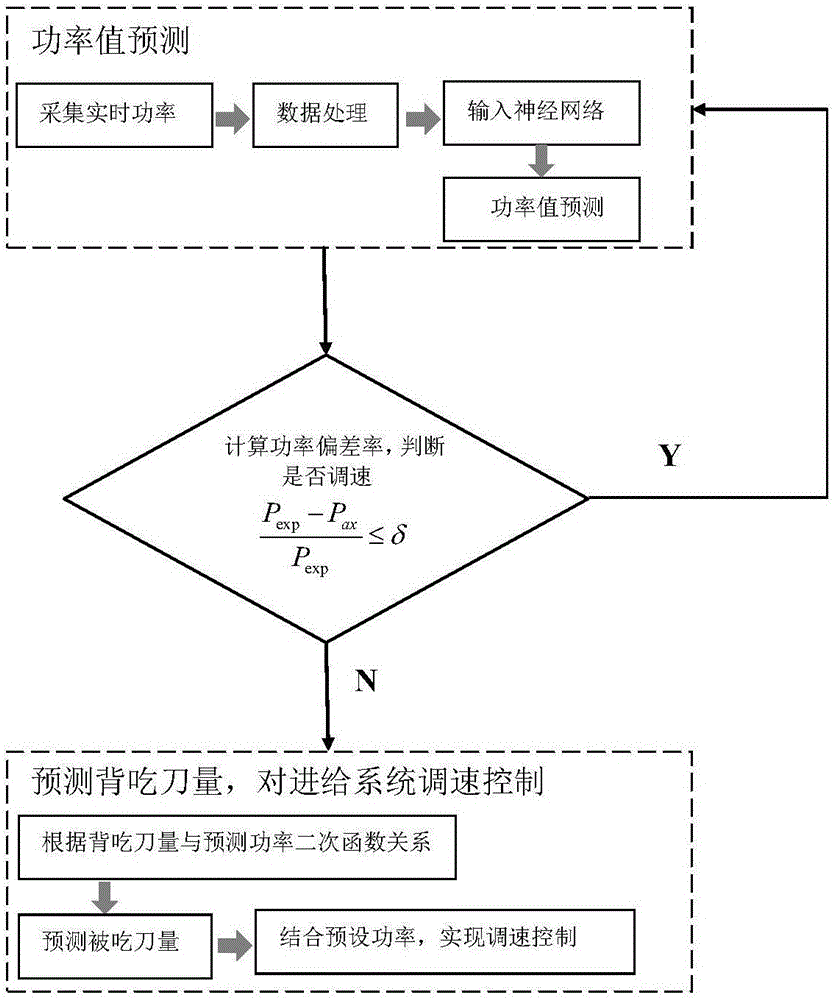

A CNC machine tool and power prediction technology, which is applied to the accessories of tool holders, metal processing equipment, turning equipment, etc., can solve the problems of poor real-time performance, long response time of the speed regulation process of the machine tool feed system, and low efficiency of the roughing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

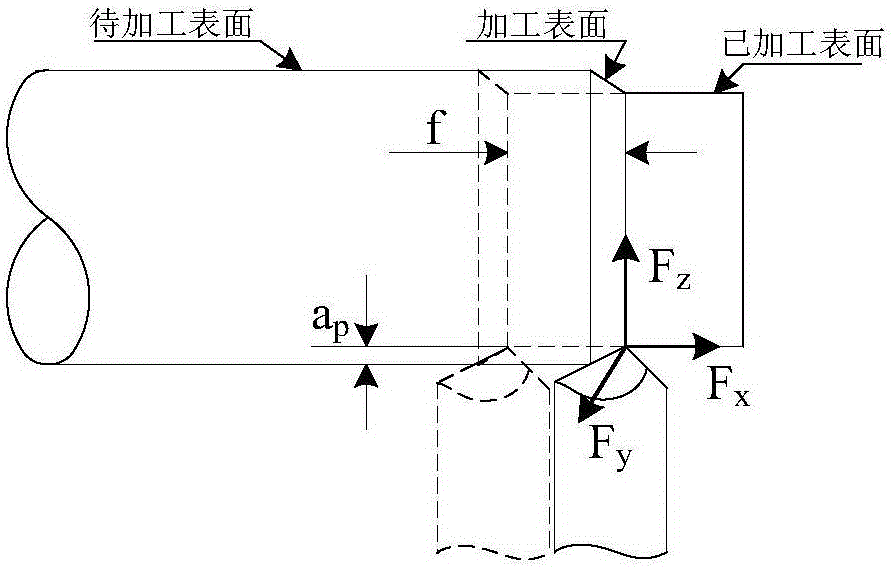

Method used

Image

Examples

Embodiment

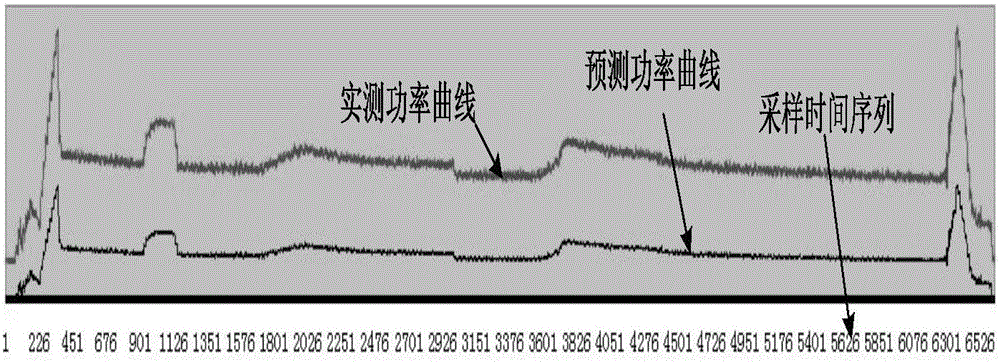

[0060] In this embodiment, the feasibility of the proposed feed speed control method is verified by a method combining experiment and simulation. When formulating the verification scheme, because the control interface of the CNC machine tool used in the experiment could not be obtained, the verification process was divided into two parts. First, the feasibility of the power prediction method is verified by testing the cutting process of the CNC machine tool; then, the static simulation analysis of the feed speed control is carried out with the measured power value as the data source.

[0061] (1) Power prediction test

[0062] The Z-axis feed system of a CNC lathe (C2-6136HK / 1) was used for the test. The basic parameters of the feed system of the machine tool are shown in Table 1, and the test conditions are shown in Table 2.

[0063] Table 1 Power related parameters (Z axis) of feed system of CNC lathe C26136HK / 1

[0064]

[0065] Table 2 Test conditions of feed system o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com