Copying cutting machine of waist-shaped hole

A cutting machine and waist-shaped hole technology, applied in welding/cutting auxiliary equipment, auxiliary devices, gas flame welding equipment, etc., can solve problems such as difficulty in adapting to waist hole processing, low production efficiency, and poor hole-making quality, and achieve structural Simple, high production efficiency, convenient production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

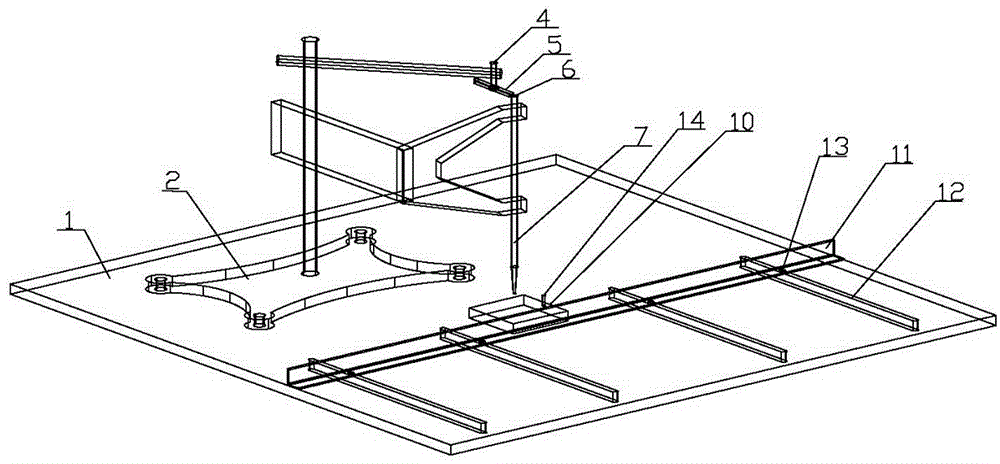

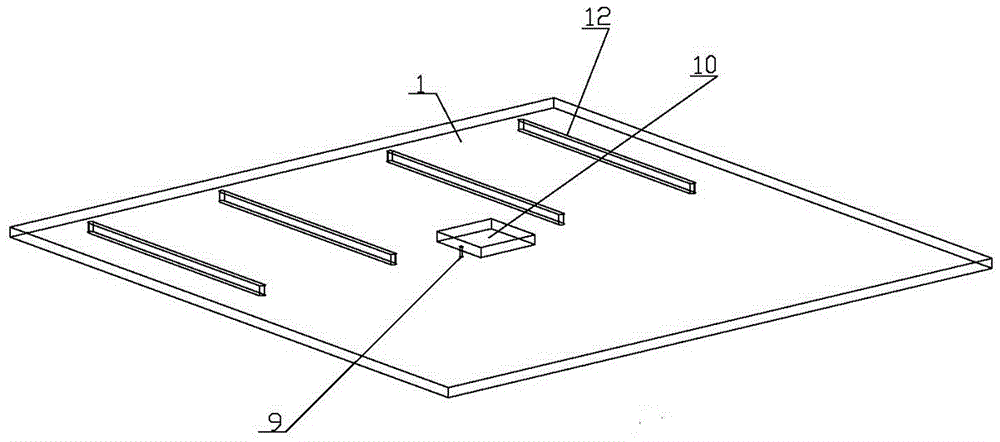

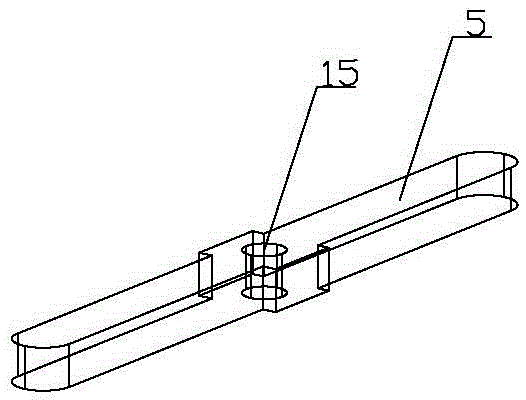

[0012] See attached figure 1 The present invention consists of an automatic cutting machine 2, an angle steel stopper 11 and a profiling model 5 arranged on a cutting platform 1, the cutting platform 1 is provided with a cutting outlet 10, a stopper chute 12 and a positioning bolt hole 9; the angle steel stopper 11 is fastened on the cutting platform 1 by the nut 13 and the stopper chute 12; the automatic cutting machine 2 is a cutting gun 7 provided with a profiling roller 6 and a profiling plate fixed shaft 4 The profiling template 5 is arranged on the profiling plate fixed shaft 4 of the automatic cutting machine 2 and is in contact with the profiling roller 6, and the cutting gun 7 is moved along the waist hole of the profiling template 5 by the profiling roller 6 The real sample shape is automatically cut and the production of the waist-shaped hole is completed.

[0013] See attached figure 2 , the cutting platform 1 is provided with a cutting outlet 10, a stopper chut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com