A laser processing device and method for annular microholes

A laser processing method and laser processing technology, which are applied in microstructure devices, manufacturing microstructure devices, laser welding equipment, etc., can solve the problems of single shape, low processing efficiency, uncontrollable micropore size, etc., and achieve simple device and processing. The effect of high efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

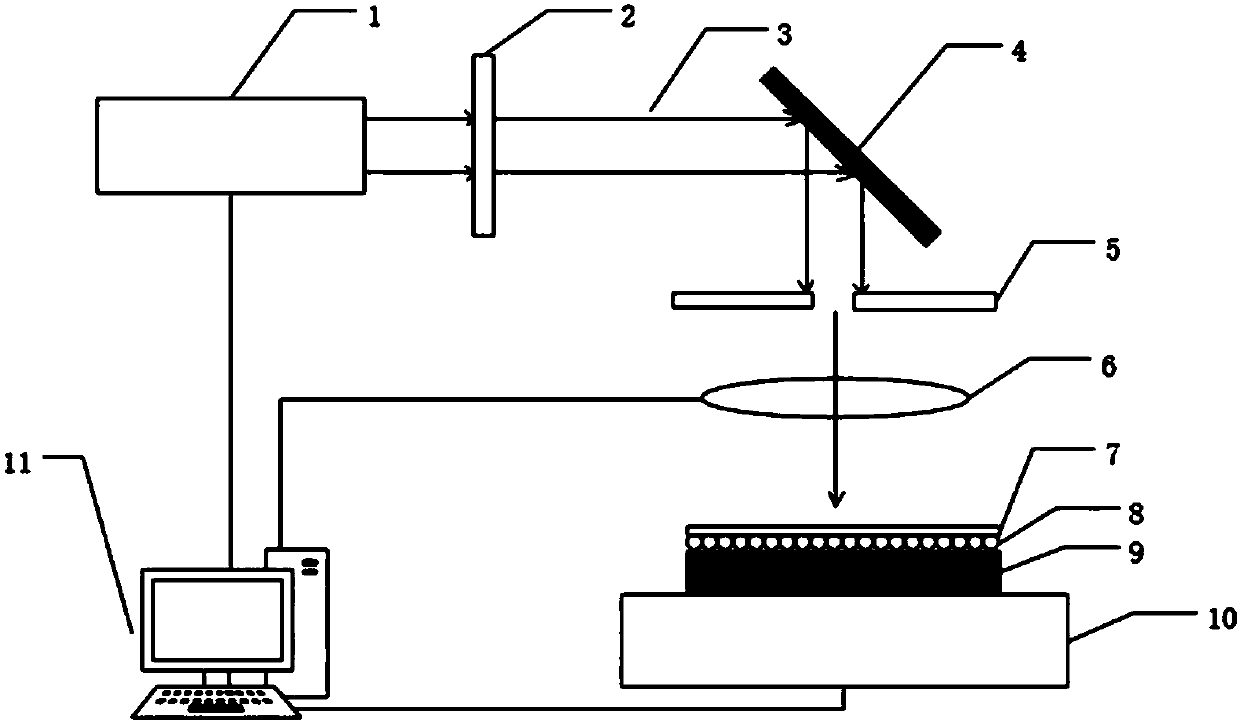

[0040] S1: Build the laser processing device of the annular microhole: adjust the pulse laser 1, the polarization control system 2 and the scanning galvanometer 4 to be in the same optical axis center; adjust the aperture 5, the focusing lens 6, the three-dimensional mobile platform 10 to the scanning galvanometer 4 At the focal point: the pulsed laser 1 , the focusing lens 6 , the three-dimensional mobile platform 10 and the computer control system 11 are electrically connected. Among them, the material of noble metal nanoparticles is gold; the laser used is IPG series pulsed fiber laser, the center wavelength is 1064nm, the repetition frequency is adjustable from 10KHz to 100KHz, the spot diameter is 50μm, and the maximum pulse energy is 1mJ;

[0041] S2: Select workpiece 9, the material is titanium alloy, the size is 20mm*20mm*5mm, and its damage threshold is J 0 =30.5mJ / cm 2 ; Pretreatment of the surface of the workpiece 9: the roughness is sequentially 120, 600, 1200, 30...

Embodiment 2

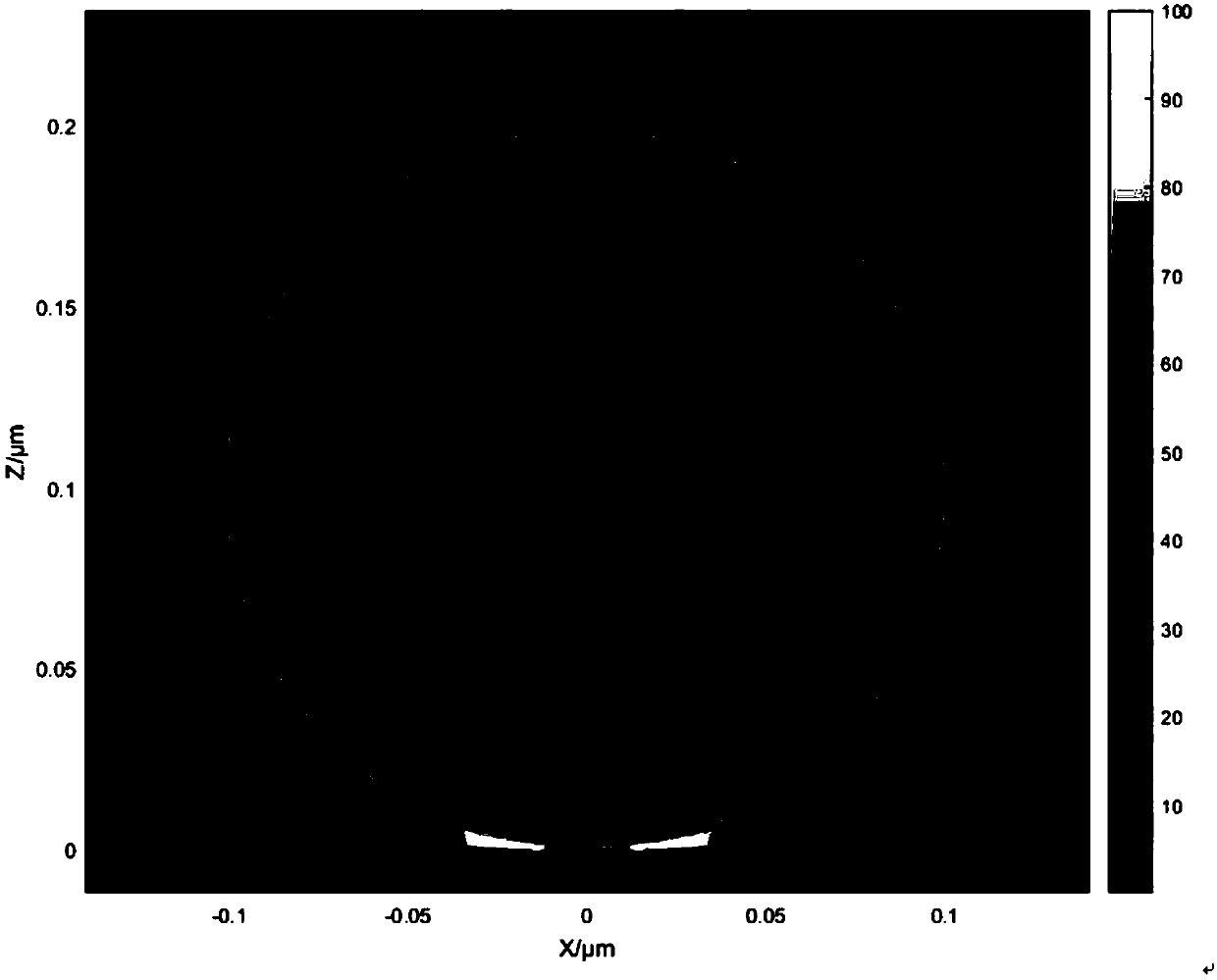

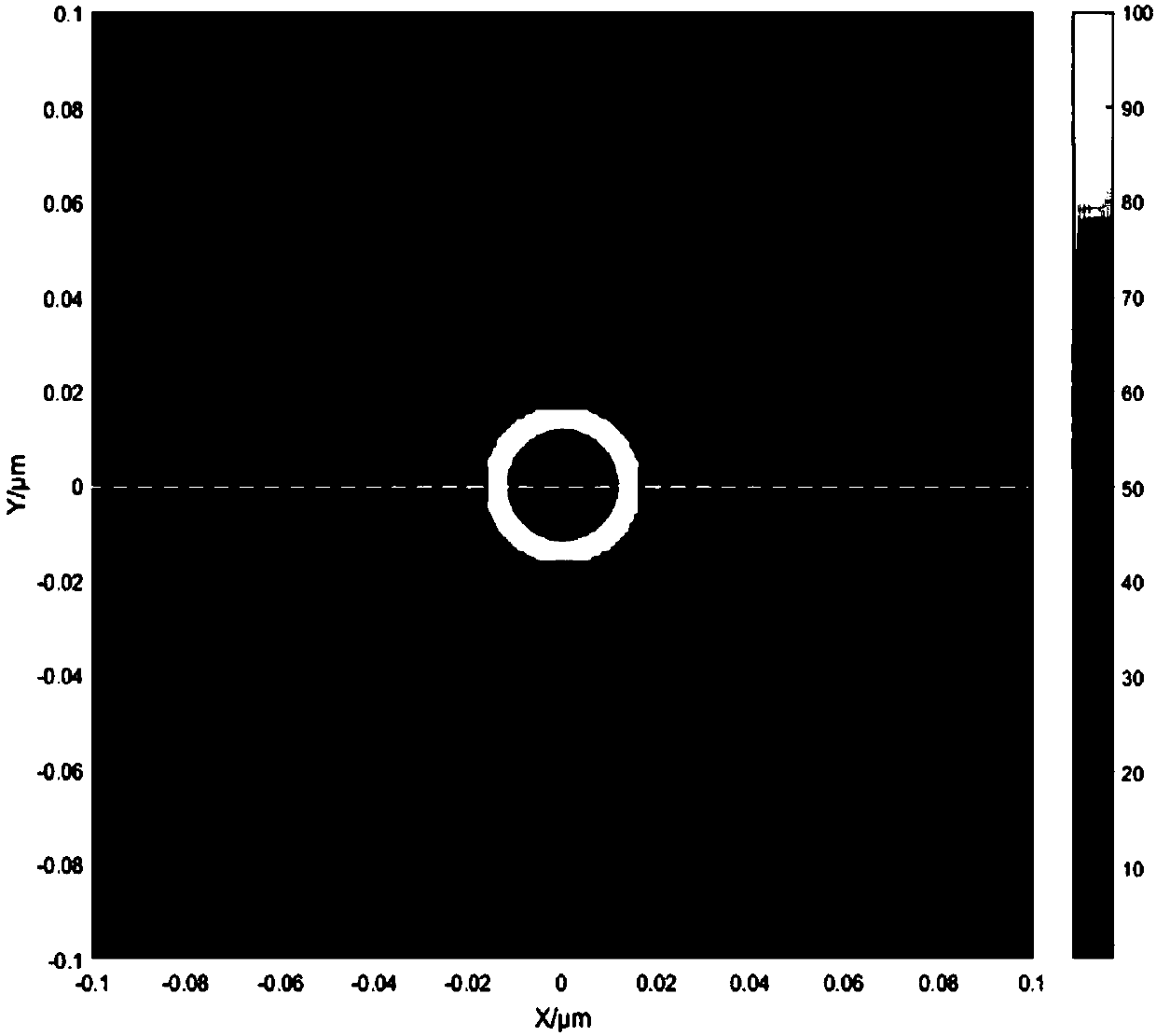

[0049] It is required to process the inner diameter of the annular microhole d=20nm, at this time p=10, satisfying op Figure 5 , according to the energy enhancement characteristic curve obtained from the solution, the energy enhancement factor A is determined d = 24.5. Turn on the computer control system, know that the spot diameter of the laser beam is 50 μm, calculate and choose the laser energy as 0.019mJ, set the repetition frequency as 50KHz, and the scanning speed as 25m / s. Other processing steps, parameters are the same as in Example 1.

[0050] Observing the processed annular micro-holes with a scanning electron microscope, it was found that the average inner diameter d of the processed annular micro-holes was 18.78nm, which was in good agreement with the processing requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com