A fast super-resolution detection device and detection method for optical element defects with random phase shift

A technology for optical components and detection devices, applied in measurement devices, material analysis by optical means, scientific instruments, etc., can solve the problems of limited industrial integration and embeddedness, inconvenient detection of optical components, limited loading frequency, etc. Achieve excellent portability, achieve super-resolution detection, and improve detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

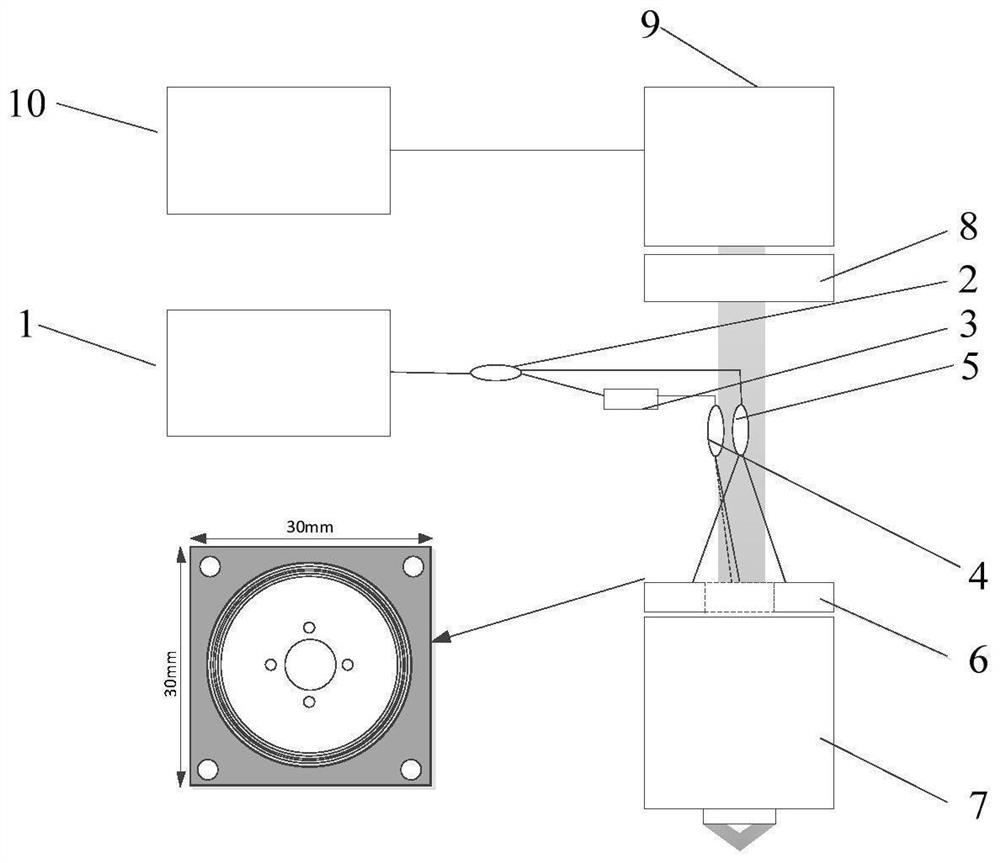

[0033] In order to achieve the goals of miniaturization, portability, high efficiency, random phase shift and low cost, the present invention provides a random phase shift optical element defect fast super-resolution detection device, the adopted technical scheme is as follows: a random phase shift A fast super-resolution detection device for optical component defects, including a laser light source 1, a 1×2 fiber coupler, a microscope objective lens 7, an imaging lens 8, a high-speed camera 9 and a computer 10, and also includes an extruded polarization controller 3, a fiber optic quasi- Straight fixing module 6, the 1×2 fiber coupler includes 1×2 fiber coupler I2, 1×2 fiber coupler II4 and 1×2 fiber coupler III5, and the laser light source 1 passes through the 1×2 fiber coupler Ⅰ2 is equally divided into two beams, one beam is adjusted by the squeeze-type polarization controller 3 to adjust the laser polarization state, and the 1×2 fiber coupler II4 is equally divided into tw...

Embodiment 2

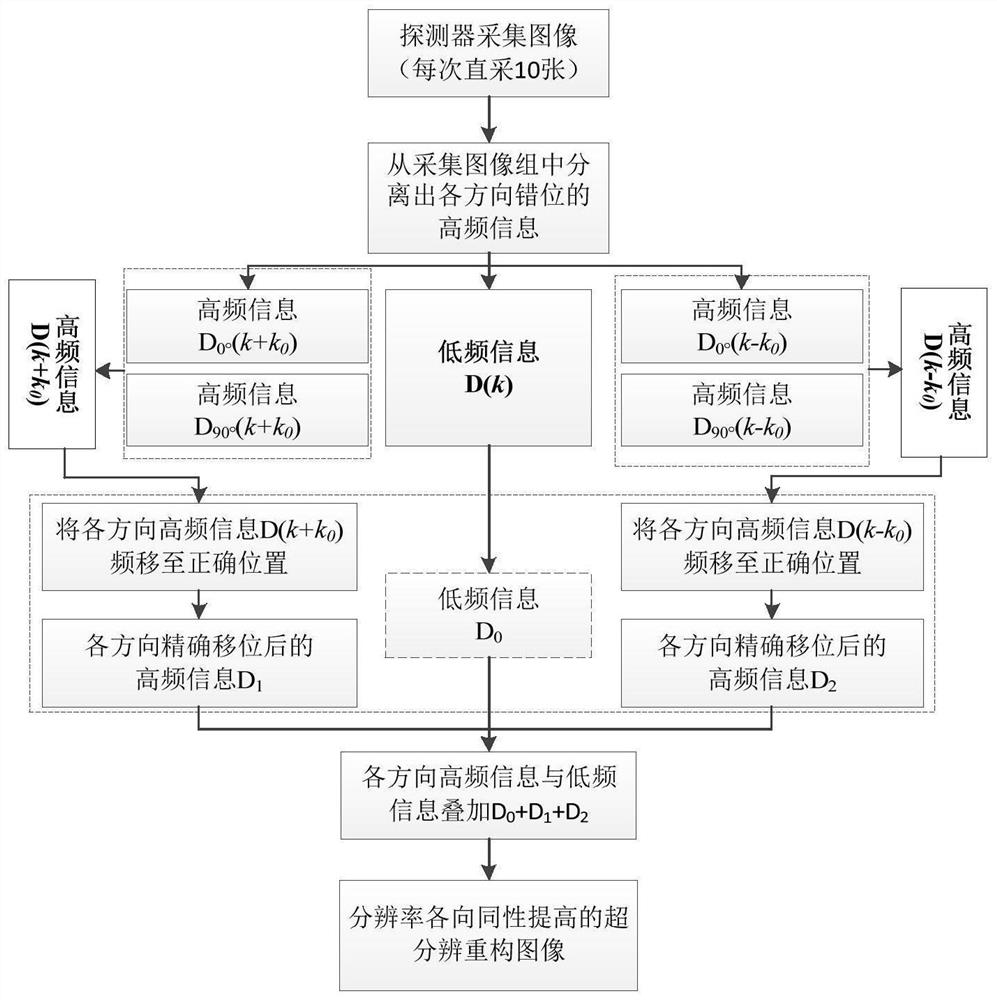

[0040] A detection method of a fast super-resolution detection device for optical element defects with random phase shifting, comprising the following steps:

[0041] Step 1: First place the test sample on the three-dimensional high-precision translation stage of the super-resolution detection device, move the Z-axis of the high-precision translation platform so that the test sample is located at the focal plane of the microscope objective lens 7 of the detection system, and adjust the high-precision translation platform X Axis and Y axis move the starting point of the sample detection area to the imaging field of view of the detection system, and adjust the imaging effect to the best;

[0042] Step 2: Set the two-dimensional scanning path of the high-precision translation stage, and accurately set the moving rate of the high-precision translation platform according to the acquisition rate of the high-speed camera 9, and complete the acquisition of the same number of original m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com