A method of rapidly transferring black phosphorus film by using polydimethylsiloxane

A technology of polydimethylsiloxane and black phosphorus, which is applied in the field of rapid transfer of black phosphorus films, can solve the problems of easy damage, low transfer efficiency, and easy pollution of black phosphorus films, and achieves low cost and good integrity , The transfer process is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In the first step, 50 mg of black phosphorus powder prepared by electrochemical assisted mechanical exfoliation was taken and uniformly dispersed in 100 ml of absolute ethanol.

[0031] In the second step, 1 ml of the above-mentioned dispersion liquid is ultrasonically dispersed in 100 ml of deionized water.

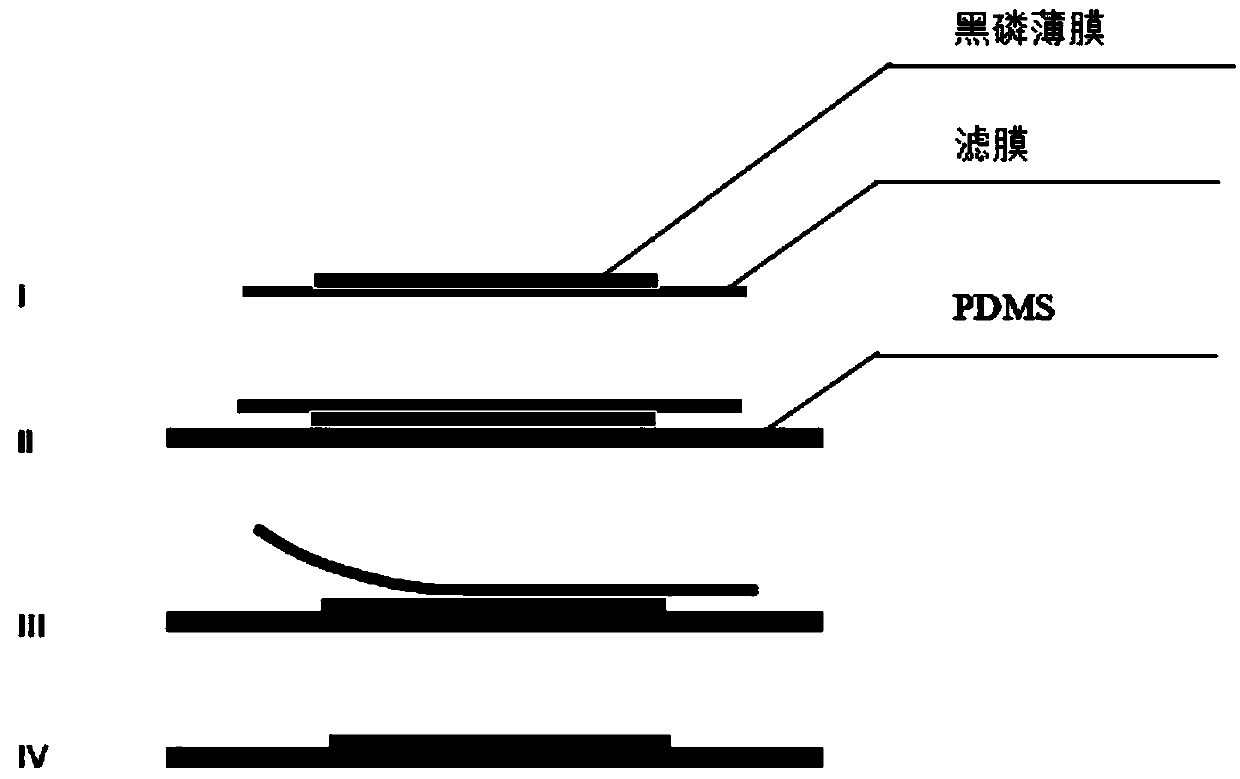

[0032] The 3rd step, use the suction filter bottle that dispersed suspension is suction filtered, use filter membrane to be acetate fiber, and obtain black phosphorus thin film (such as figure 1 I).

[0033] In the fourth step, the 100 micron thick PDMS film is tightly attached to the filter membrane with the black phosphorus side, and gently pressed, the filter membrane is in a wet state in this step (such as figure 1 II).

[0034] The fifth step, after 5 minutes, take off the filter membrane (such as figure 1 II), that is, the black phosphorus film transferred to PDMS (such as figure 1 IV).

[0035] It should be noted that the illustrations provided in the ...

Embodiment 2

[0037] The preparation method is basically the same as in Example 1, except that the black phosphorus powder is prepared by redox method.

Embodiment 3

[0039] The preparation method is basically the same as in Example 1, except that the black phosphorus powder is prepared by mechanical exfoliation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com