Gas-carbon co-production device

A gas-charcoal and reaction device technology, applied in the gasification process, the manufacture of combustible gas, the petroleum industry, etc., can solve problems such as low work efficiency, and achieve the effect of improving efficiency, preventing accumulation, and preventing stuck or stuck.

Inactive Publication Date: 2016-09-21

FUJIAN MINAN MACHINERY MFG

View PDF2 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Moreover, after the charcoal is burned, it often needs to be manually cleaned and discharged, and the work efficiency is low.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0017] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

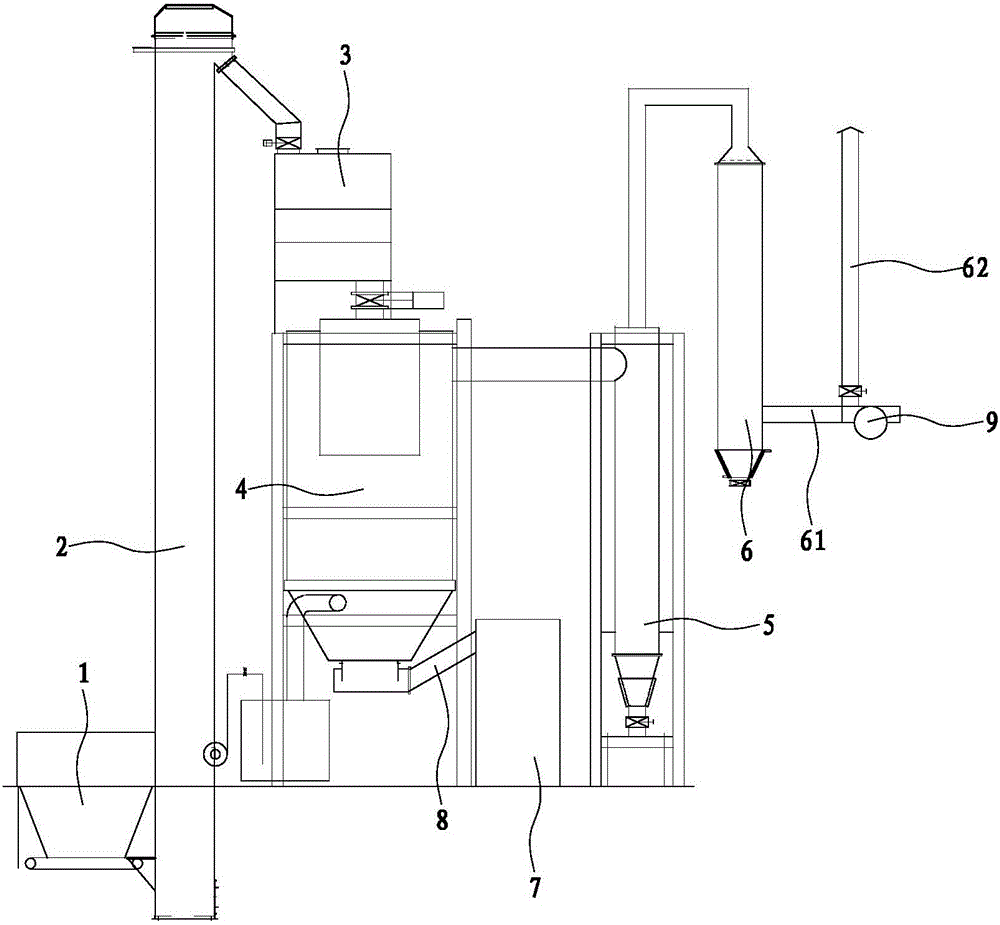

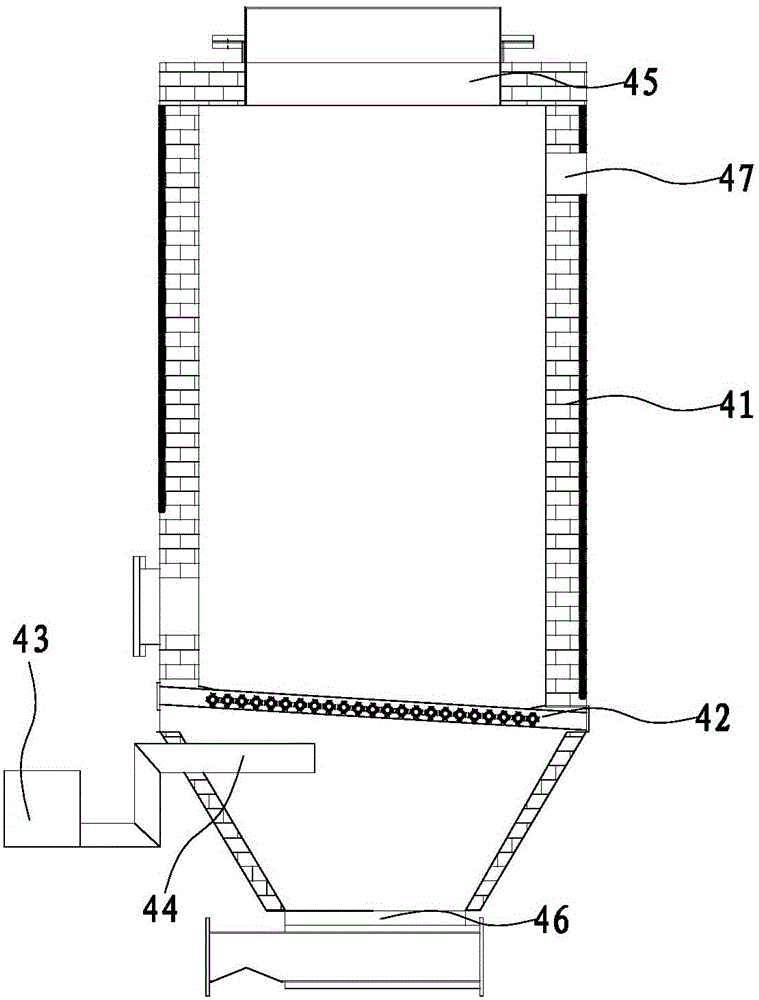

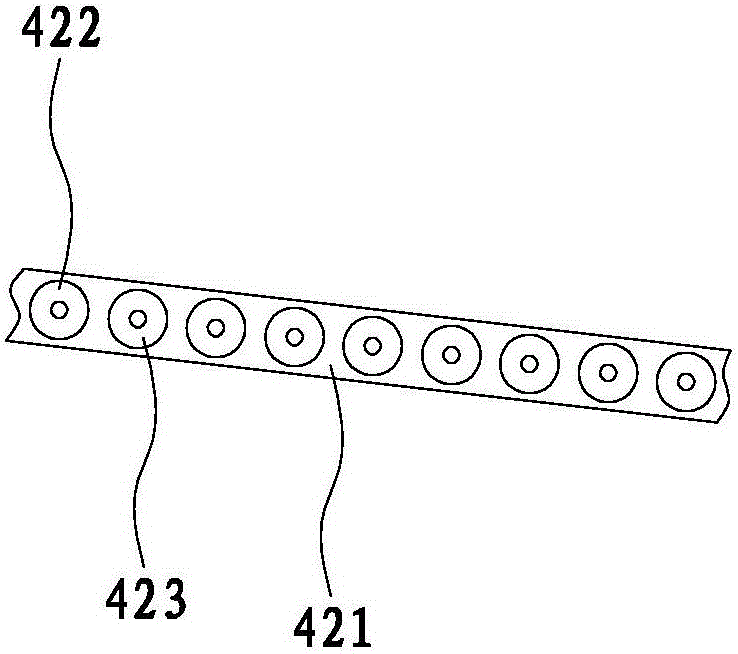

The invention relates to a gas-carbon co-production device, comprising a rack, and a hopper, a reaction device, a gas purifying device used for purifying gas output by the reaction device and a gas water treatment device used for removing water contained in the gas which are arranged on the rack according to a production line, wherein the reaction device comprises a furnace body, a fire grate arranged in the furnace body, an air blower arranged outside the furnace body, and a blower tube which is arranged under the fire grate and is communicated with the air blower; a feeding hole communicated with the hopper is formed in the upper end of the furnace body, and a slag hole is formed in the lower end of the furnace body; a gas outlet communicated with the gas purifying device is formed in the furnace body; the rack is provided with a crusher; a spiral conveyor used for conveying carbon residue discharged by the furnace body into the crusher is arranged on the rack and between the crusher and the slag hole; the gas water treatment device is connected with a gas conveying pipeline.

Description

technical field [0001] The invention relates to a gas-carbon cogeneration device. Background technique [0002] At present, the gas produced by the existing gas-carbon cogeneration equipment often has a lot of dust particles and oil particles when it is output, resulting in a lower combustion rate, and more combustion impurities, which may even lead to incombustibility. Moreover, after the wood is damp and burned, a large amount of water vapor will be produced, so the output gas will contain water vapor, which also leads to a low combustion rate. How to remove dust particles, oil particles, and water vapor has become the key. Moreover, after the charcoal is burned, it often needs to be manually cleaned and discharged, and the work efficiency is low. Contents of the invention [0003] Therefore, in view of the above problems, the present invention proposes a gas-carbon cogeneration device with clean output gas, low gas moisture content, and automatic charcoal discharge an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10J3/00C10J3/84C10J3/72

CPCC10J3/00C10J3/72C10J3/84C10J2300/0906C10J2300/1603

Inventor 刘阿小戴海珊吴联平戴琪琳张公敏傅德丙

Owner FUJIAN MINAN MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com