Abrasion-resistant corrosion-resistant composite alloy roller barrel and production process

A composite alloy and roll technology, which is applied in the field of roll production, can solve the problems of wasting steel materials, corroded, and high production costs, and achieve the effects of improving production and manufacturing accuracy, improving corrosion resistance, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

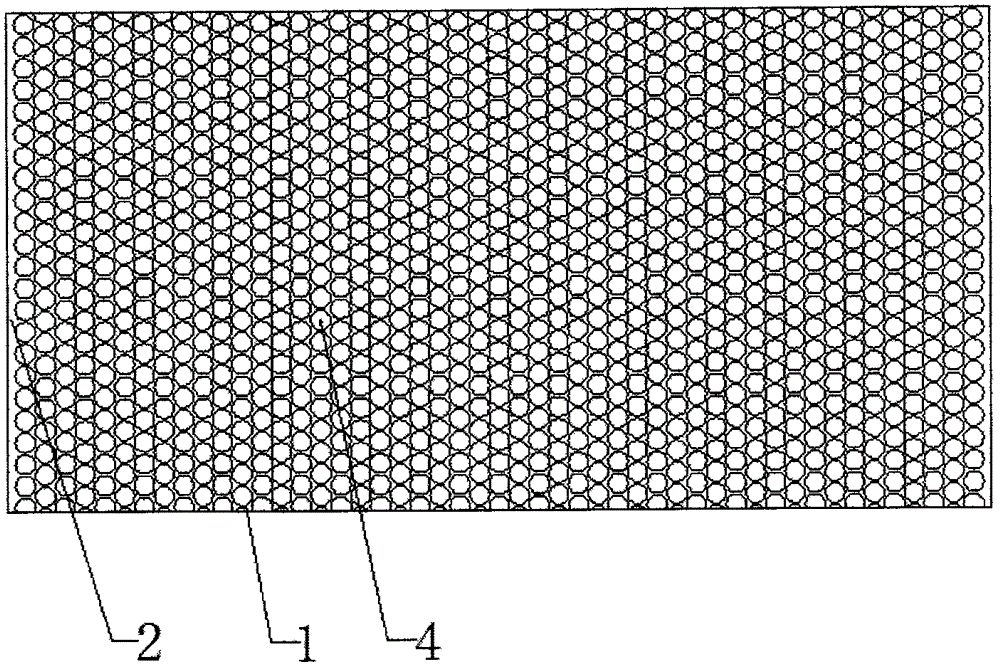

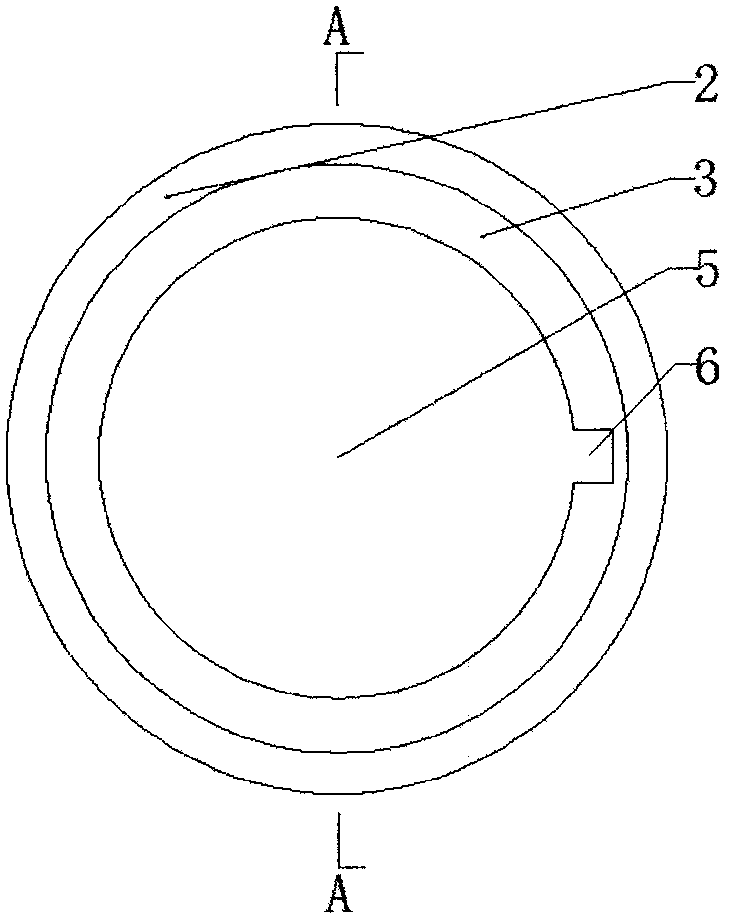

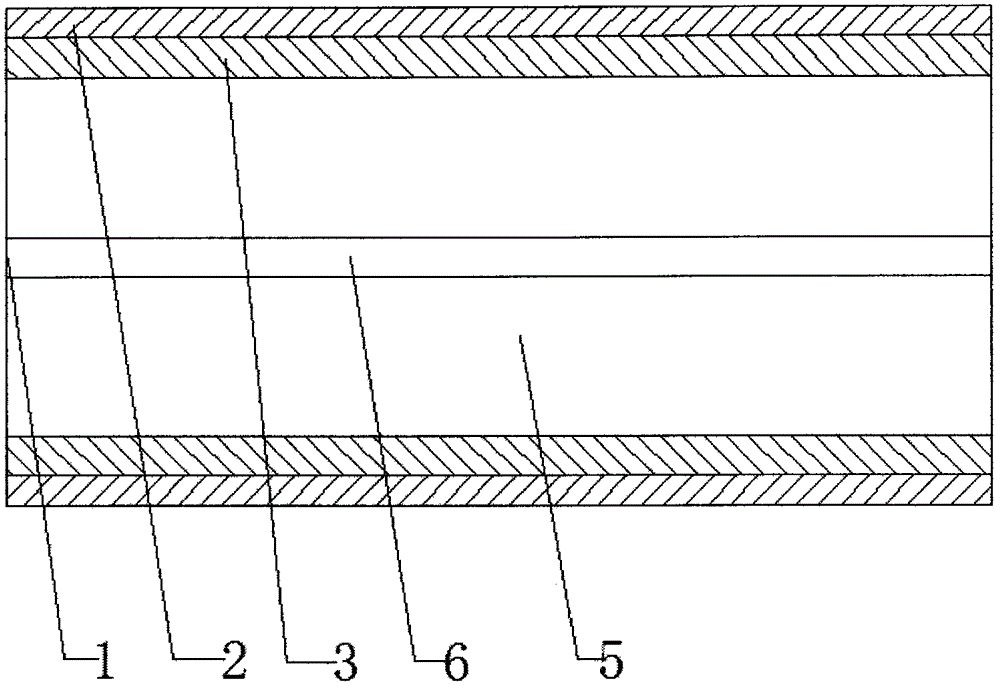

[0031] as attached Figure 1-3 As shown, the wear-resistant and corrosion-resistant composite alloy roll and its production process include a roll body 1, the roll body 1 is a hollow cylinder, and the roll body 1 is composed of an alloy steel layer 2 and an ordinary steel layer 3, The inner side of the alloy steel layer 3 is integrally cast to set the ordinary steel layer 2, and the alloy steel layer 3 includes the following components by mass percentage: C: 0.4% Si: 0.6% Mn: 0.8% P: 0.025% S: 0.025% Cr: 17.0% Ni: 1.0% Mo: 0.6% V: 0.06% Ti: 0.03% Al: 0.06% Cu: 0.3% W: 0.01% Re: 0.01% The rest is Fe and unavoidable impurities;

[0032] The production process of wear-resistant and corrosion-resistant composite alloy roll includes the following steps:

[0033] g. Production of molten steel: add raw materials according to the above ratio and enter them into alloy steel furnaces for melting, so that various components are evenly mixed, and at the same time, put the raw materials o...

Embodiment 2

[0044] as attached Figure 1-3 As shown, the wear-resistant and corrosion-resistant composite alloy roll and its production process include a roll body 1, the roll body 1 is a hollow cylinder, and the roll body 1 is composed of an alloy steel layer 2 and an ordinary steel layer 3 The inner side of the alloy steel layer 3 is integrally cast to set the ordinary steel layer 2, and the alloy steel layer 3 includes the following components by mass percentage: C: 0.8% Si: 1.0% Mn: 1.1% P: 0.035% S : 0.035% Cr: 18.0% Ni: 1.3% Mo: 0.9% V: 0.09% Ti: 0.06% Al: 0.08% Cu: 0.5% W: 0.03% Re: 0.03% The rest is Fe and unavoidable impurities;

[0045] The production process of wear-resistant and corrosion-resistant composite alloy roll includes the following steps:

[0046] m. Production of molten steel: Add raw materials according to the above ratio and enter them into alloy steel furnaces for melting, so that various components are evenly mixed, and at the same time, put the raw materials o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com