Magnetron Sputtering Device

A technology of magnetron sputtering device and monitoring device, which is applied in the direction of sputtering coating, vacuum evaporation coating, coating, etc., which can solve the problems of increased uncertainty, difficulty in adjusting the magnetic target distance, and the inability to monitor the consumption of target materials and other issues to achieve the effect of ensuring uniformity and stability and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further explain the technical means and effects adopted by the present invention to achieve the intended invention purpose, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0018] The orientations "upper" and "lower" mentioned in the description of the present invention are only used to indicate the relative orientation relationship, and refer to the positional relationship embodied in the drawings of the specification.

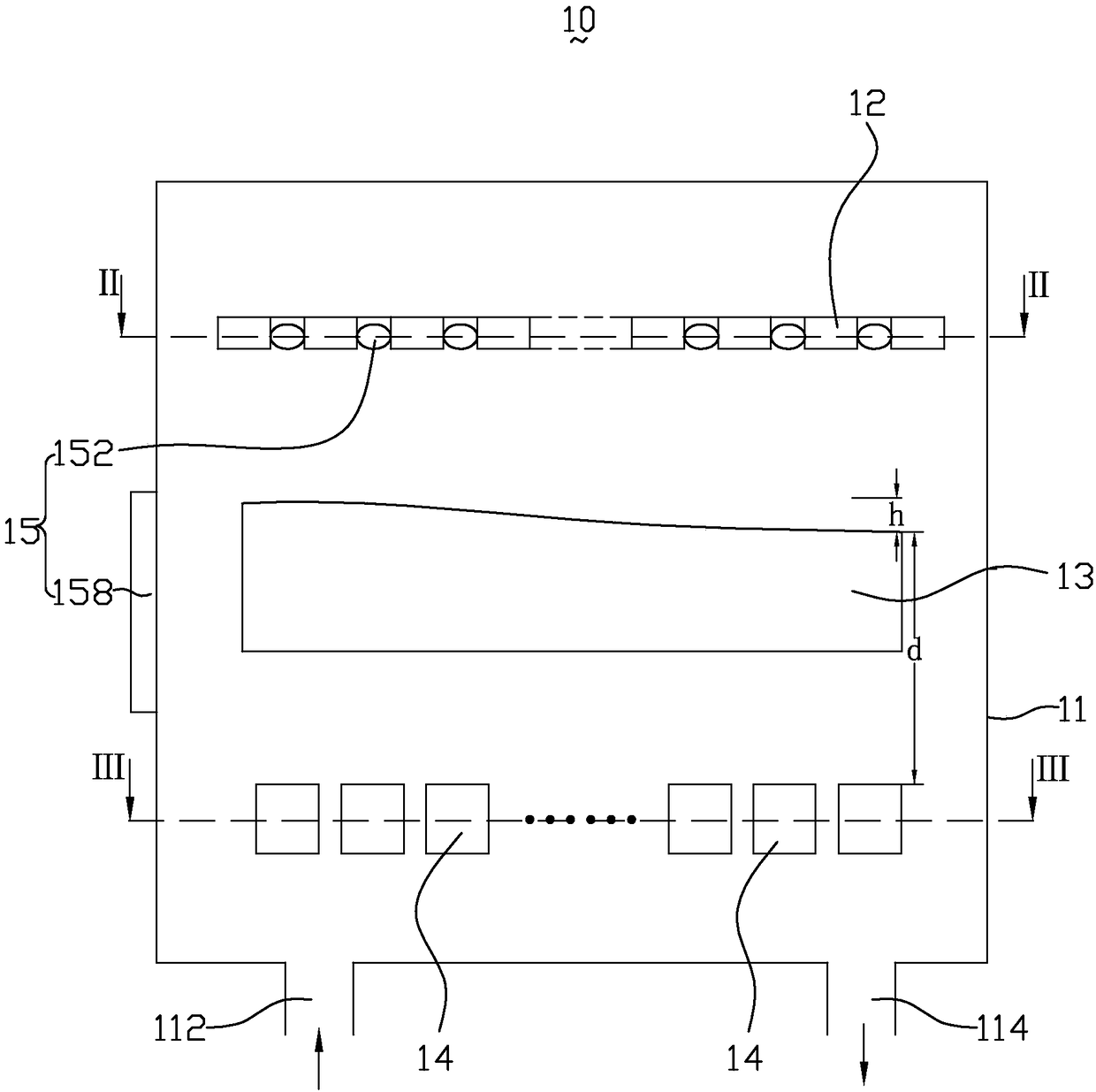

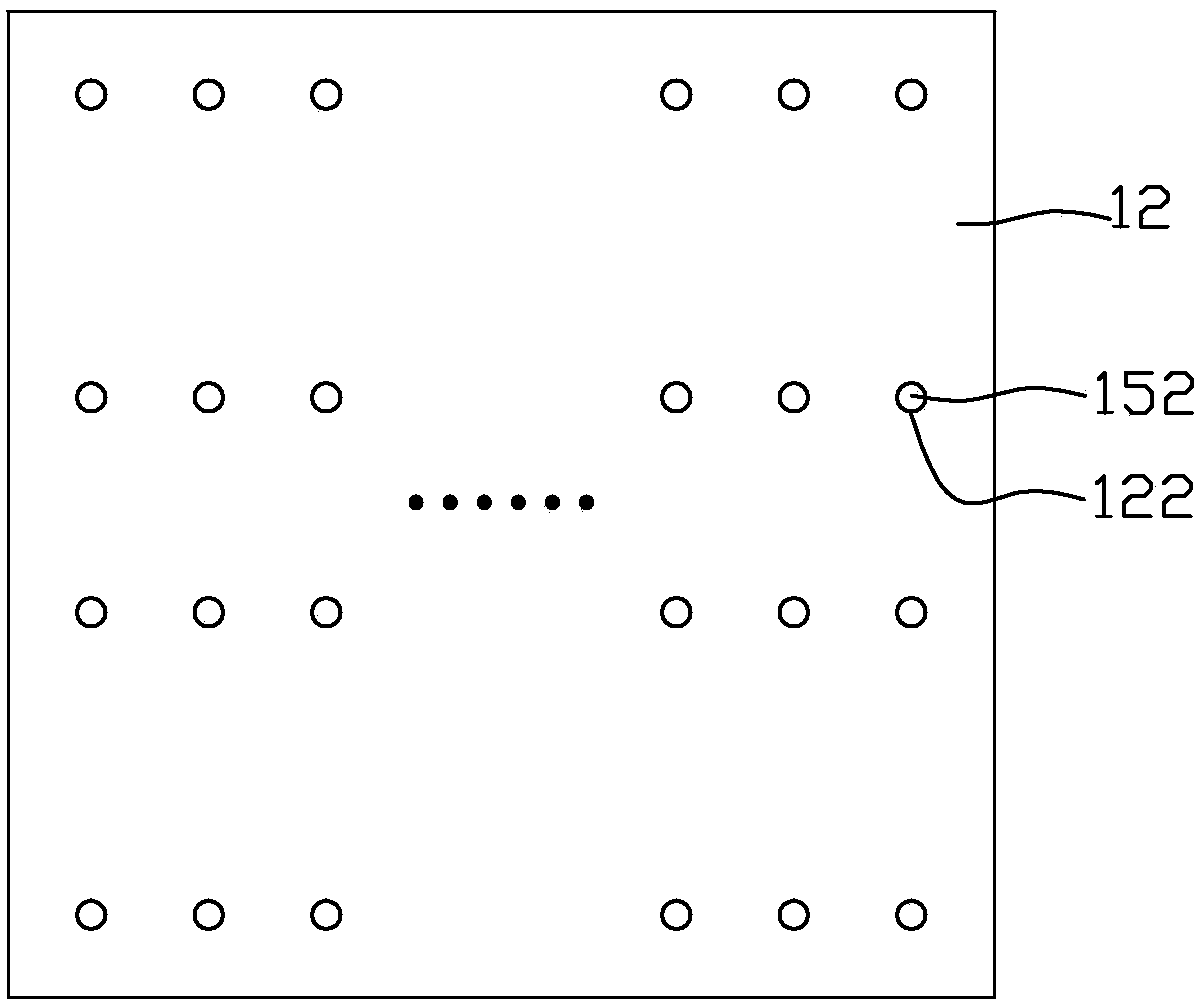

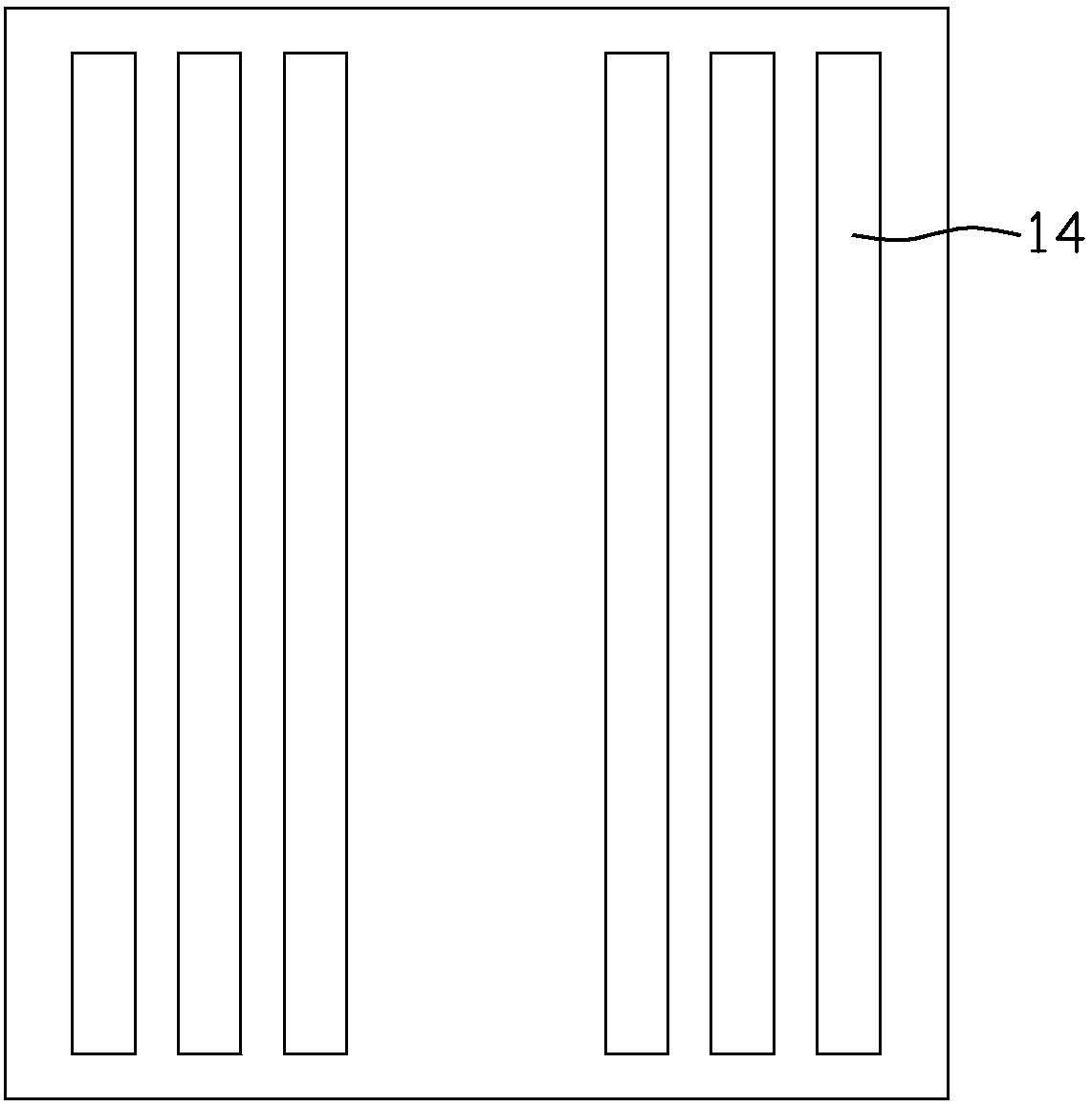

[0019] figure 1 is a schematic structural view of the magnetron sputtering device of the present invention, figure 2 yes figure 1 The cross-sectional view at II-II, image 3 yes figure 1 For the cross-sectional view at III-III, please refer to Figure 1 to Figure 3 As shown, the magnetron sputtering device 10 includes a working chamber 11 , a substrate 12 , a target 13 , a magnet 14 , and a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com