Cleaning control method and system of heat exchanger for clothes dryer and clothes dryer

A technology of a control system and a control method, which is applied in the field of clothes dryers, can solve problems such as the inability to clean the dander on the surface of the heat exchanger, the uneven distribution of dross at the boundary of the heat exchanger, and the impact on the heat transfer effect of the heat exchanger. Achieve the effects of avoiding useless cleaning, increasing water pressure and improving impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0045] A cleaning control method for a heat exchanger for a clothes dryer, a cleaning control system for a heat exchanger for a clothes dryer, and a clothes dryer according to embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

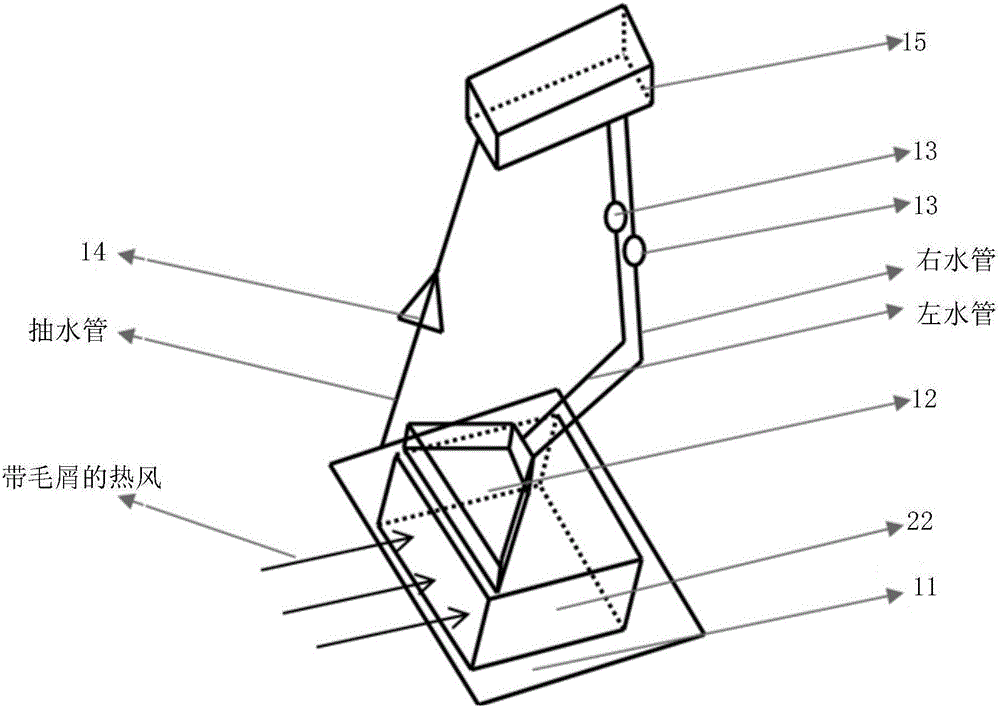

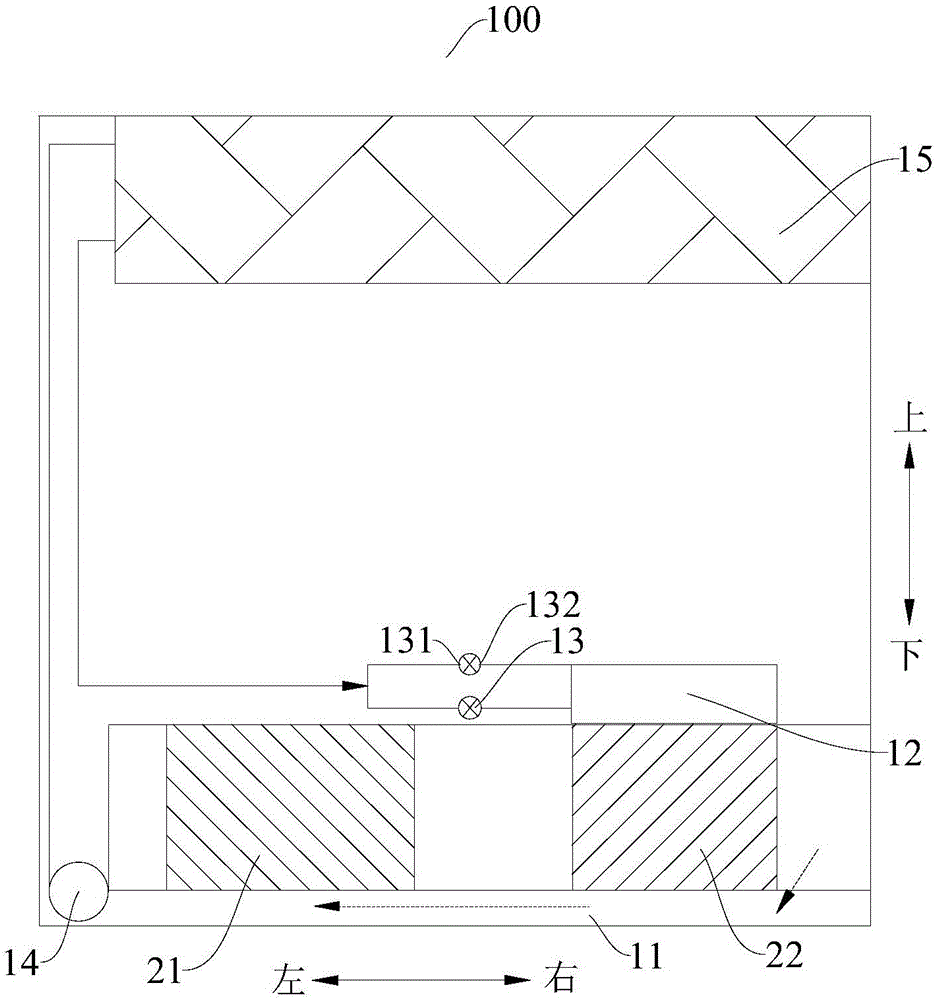

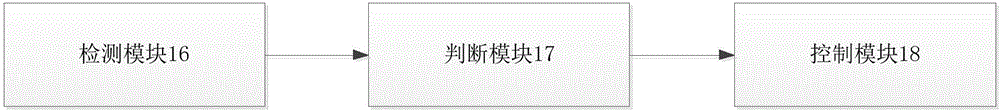

[0046] combine Figure 1 to Figure 3 As shown, a cleaning control system 100 for a heat exchanger for a clothes dryer according to an embodiment of the present invention includes a water collector 11 , a water nozzle 12 , a pump body 14 , a water storage tank 15 , a detection module 16 , a judgment module 17 and a control module 18 . Specifically, the water collector 11 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com