Oil shale in situ heat injection exploitation drilling well cementation method

An oil shale and well cementing technology, which is applied in the cementing of oil shale in-situ thermal injection drilling, oil sand thermal injection production, and heavy oil fields, and can solve oil stringing accidents, steam stringing, cementing casing, Problems such as deformation and damage of the cement sheath, to achieve the effects of preventing steam passing, high cementing strength, and improving cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

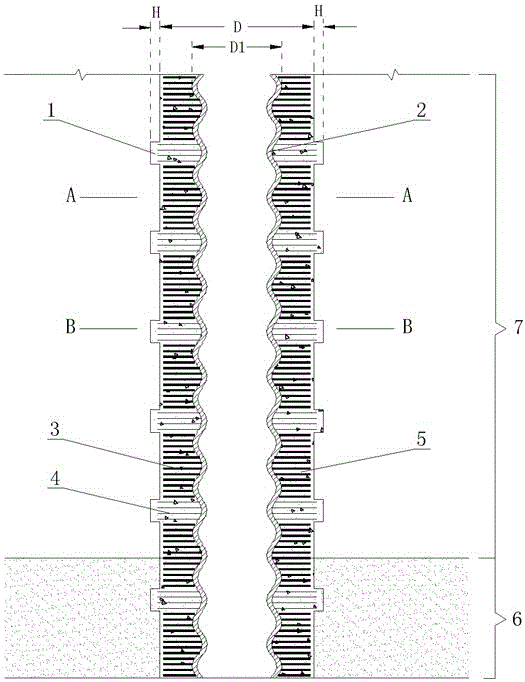

[0023] Such as figure 1 , 2 , Shown in 3, a kind of concrete steps of the well cementing method of oil shale in-situ thermal injection exploitation drilling:

[0024] 1. Drilling in the target in-situ heat injection area of the selected oil shale 6 to form a borehole with an inner diameter of D=450 mm, and then space a certain length in the borehole to expand the diameter of the drill hole in the formation to form a ring groove 1. The ring The depth of groove 1 H=30mm;

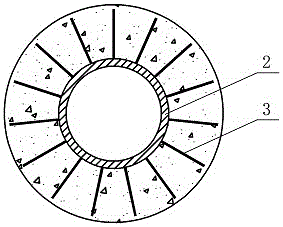

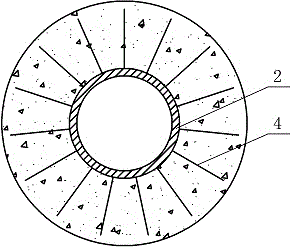

[0025] 2. Select diameter D 1 = 300mm metal bellows is the cementing casing 2, and steel bars 3 and steel wires 4 are evenly welded radially outside the cementing casing 2, and the position of the steel wire 4 corresponds to the position of the ring groove 1;

[0026] 3. Press the cementing casing 2 that has been welded with the steel bar 3 and the steel wire 4 into the borehole, and the depth that the steel wire 4 penetrates into the ring groove 1 is 5 mm;

[0027] 4. Use high-temperature resistant ceme...

Embodiment 2

[0032] Such as figure 1 , 2 , Shown in 3, a kind of concrete steps of the well cementing method of oil shale in-situ thermal injection exploitation drilling:

[0033] 1. Drilling in the target in-situ heat injection area of the selected oil shale 6 to form a borehole with an inner diameter of D=650 mm, and then space a certain length in the borehole to expand the diameter of the drill hole in the formation to form a ring groove 1. The ring The depth of groove 1 H=100mm;

[0034] 2. Select diameter D 1 = 450mm metal bellows is the cementing casing 2, and steel bars 3 and steel wires 4 are evenly welded radially outside the cementing casing 2, and the position of the steel wire 4 corresponds to the position of the ring groove 1;

[0035] 3. Press the cementing casing 2 that has been welded with the steel bar 3 and the steel wire 4 into the borehole, and the depth of the steel wire 4 penetrating into the ring groove 1 is 30mm;

[0036] 4. Use high-temperature resistant ceme...

Embodiment 3

[0041] Such as figure 1 , 2 , Shown in 3, a kind of concrete steps of the well cementing method of oil shale in-situ thermal injection exploitation drilling:

[0042] 1. Drilling in the target in-situ heat injection area of the selected oil shale 6 to form a borehole with an inner diameter of D=550 mm, and then space a certain length in the borehole to expand the diameter of the drill hole in the formation to form a ring groove 1. The ring The depth of groove 1 H=60mm;

[0043] 2. Select diameter D 1 The metal bellows of =350mm is the cementing casing 2, and steel bars 3 and steel wires 4 are evenly welded radially outside the cementing casing 2, and the position of the steel wire 4 corresponds to the position of the ring groove 1;

[0044] 3. Press the cementing casing 2 that has been welded with the steel bar 3 and steel wire 4 into the borehole, and the depth that the steel wire 4 penetrates into the ring groove 1 is 15mm;

[0045] 4. Use high-temperature resistant ce...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap