A hydraulic/pneumatic high pressure relief valve

A pneumatic high-pressure, pressure relief valve technology, applied in the field of pressure relief valves, can solve problems such as danger, abnormal equipment operation, pipeline leakage, etc., and achieve the effect of light weight, small size and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] This embodiment provides a hydraulic high-pressure pressure relief valve, which can adapt to 60MPa high-pressure oil, is small in size, light in weight, good in safety and high in reliability, and can realize remote pressure relief.

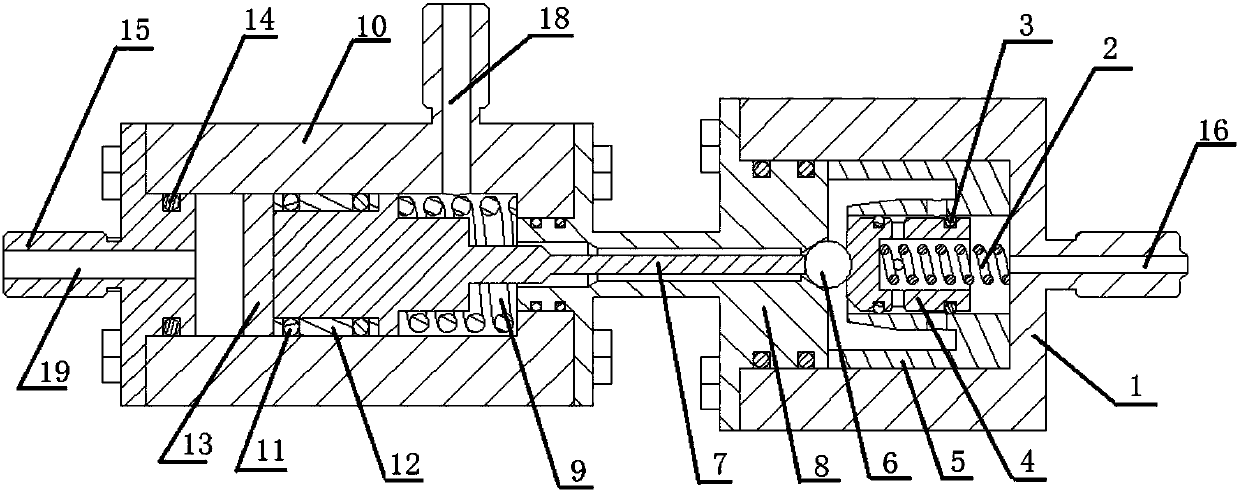

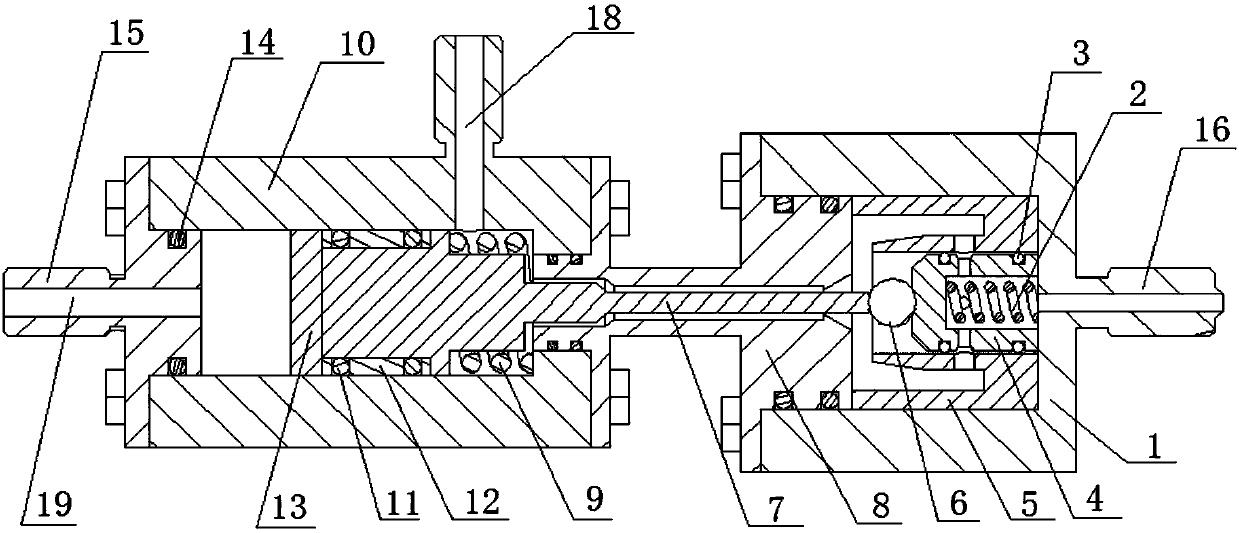

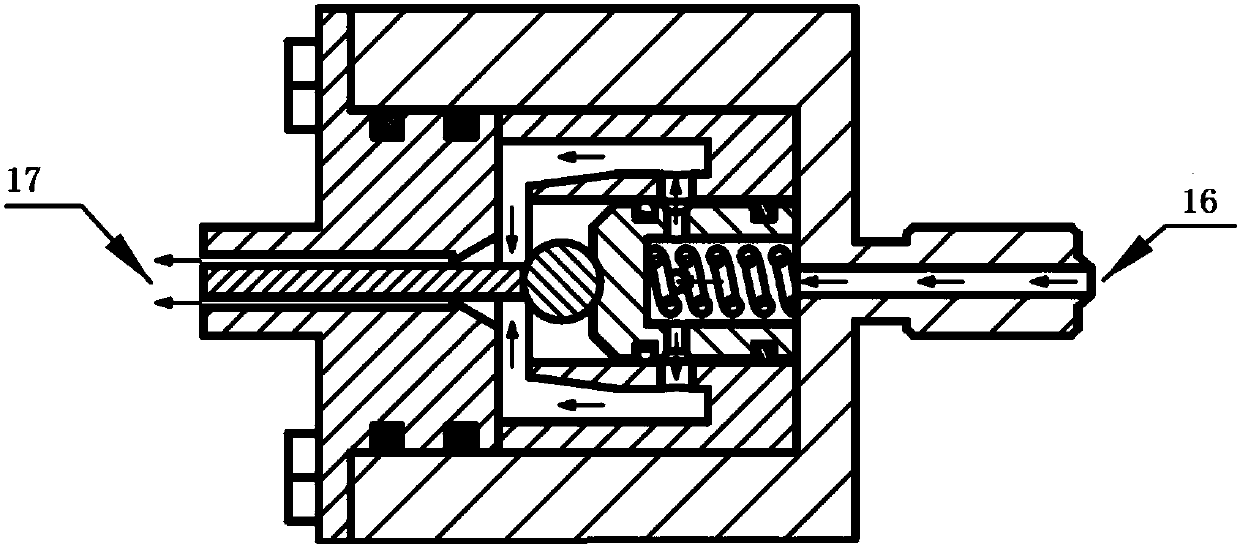

[0019] Such as figure 1 and figure 2 As shown, the high pressure relief valve has three ports connected to the outside, which are high pressure oil port 16 , low pressure oil port 19 and oil return port 18 .

[0020] Its overall structure includes a hyperbaric chamber, a low pressure chamber and a connecting flange 8, wherein the hyperbaric chamber includes: a hyperbaric chamber shell 1 and a hyperbaric chamber spring 2 located inside the hyperbaric chamber shell 1, a cylindrical valve core 4 and a throttle chamber 5 . The hyperbaric chamber shell 1 is a structure with one end open and one end closed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com