Crawler-type paperboard dryer

A dryer and crawler-type technology, applied in the field of cardboard printing, can solve the problems such as the inability to meet the large-scale dehumidification due to space constraints, the large influence of external environmental factors, and the failure to achieve expected results, and achieve continuous and stable automatic control, Save labor costs and have little impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

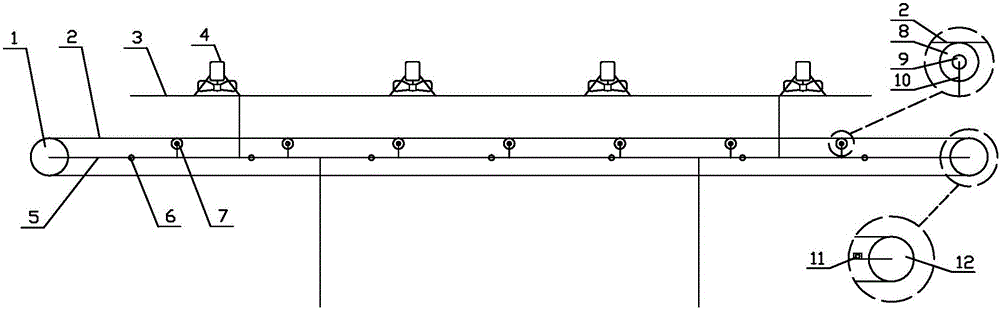

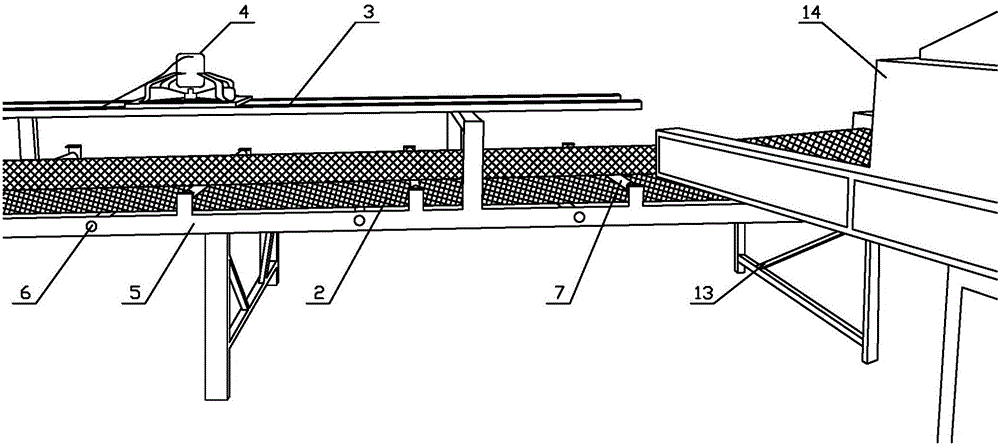

[0014] refer to figure 1 , figure 2 , a crawler-type cardboard dryer of the present invention, comprising a bracket 5, a driving device 1 is fixedly installed at both ends of the middle layer of the bracket 5, the driving device 1 is connected to a conveyor belt 2, the conveyor belt 2 is a closed loop conveyor belt, and the bracket 5 The middle layer is also fixed with a plurality of supporting components 7, the supporting components 7 are located between the 2 rings of the conveyor belt, a plurality of light pipes 6 are installed on the bracket 5, the light pipes 6 are located in the middle of the 2 rings of the conveyor belt, and the top layer of the bracket 5 is fixed with a fixed cross bar 3. A plurality of exhaust fans 4 are installed on the fixed crossbar 3, and the exhaust fans 4 are located above the conveyor belt 2, and the light pipe 6 is an electric heating pipe. Due to the adoption of the above-mentioned structure in this crawler-type cardboard dryer, the mounted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com