Vertical-surface wheel chute chromium-alloy periphery-adjustable engineering rubber clamp

A technology of engineering rubber and chromium alloy, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of uneven force around the surrounding, waste and pollution, and long time-consuming, so as to save the cost of testing consumables and avoid polluting the environment , The effect of shortening the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

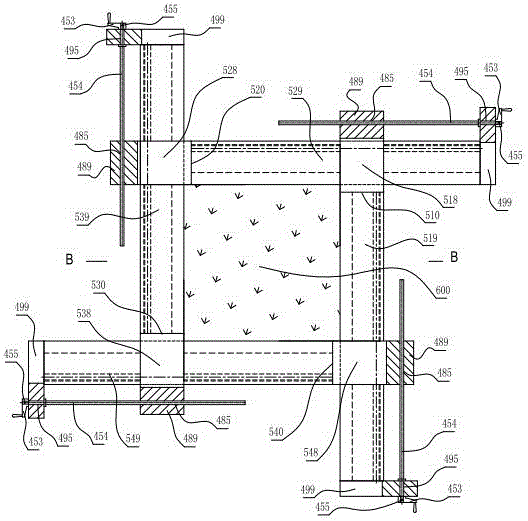

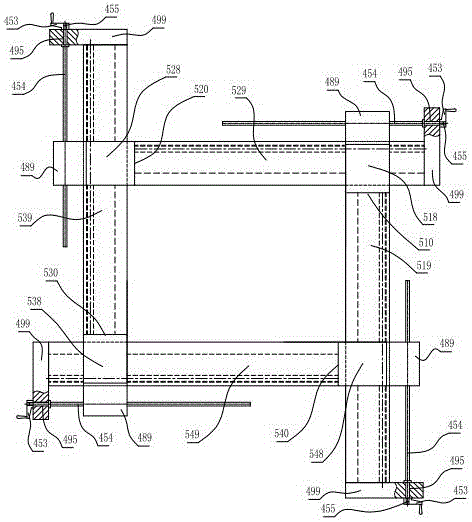

[0048] Describe the present invention in detail below in conjunction with accompanying drawing and specific embodiment: Figure 16 In , the tempered glass plate 600 is fixed and placed on the test bench plate 190 .

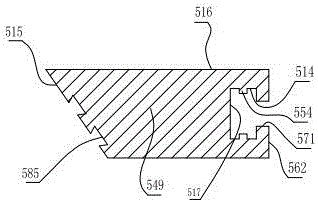

[0049] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 8 , Figure 11 , Figure 12 , Figure 13 and Figure 16 Middle: The chrome alloy peripheral adjustment engineering rubber clamps of the façade wheel chute, including four first sliding clamps 510, second sliding clamps 520, third sliding clamps 530 and fourth sliding clamps with the same structural size Move by the pliers 540, each by the pliers part and the sliding part, the first sliding pliers 510 is composed of the first pliers part 519 and the first sliding part 518, the second sliding pliers 520 is composed of the second jaw part 529 and the second sliding part 528, the third sliding jaw 530 is composed of the third jaw part 539 and the third sliding part 538, and the fourth s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com