Liquid-film-thickness-controllable thin liquid film corrosion electrochemical testing device and method

A liquid film thickness, electrochemical technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, scientific instruments, etc., can solve the problems of lack of accurate and effective control devices and methods, limitations of electrochemical testing of thin liquid film corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0017] The invention provides a thin liquid film corrosion electrochemical test device and method with controllable liquid film thickness.

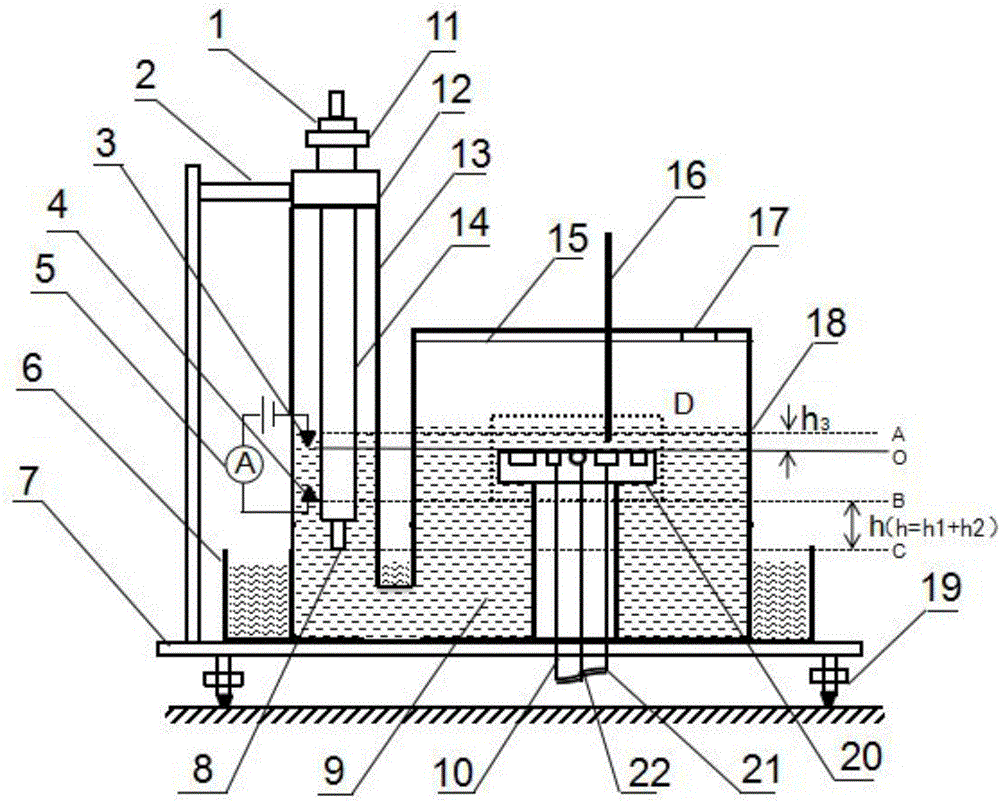

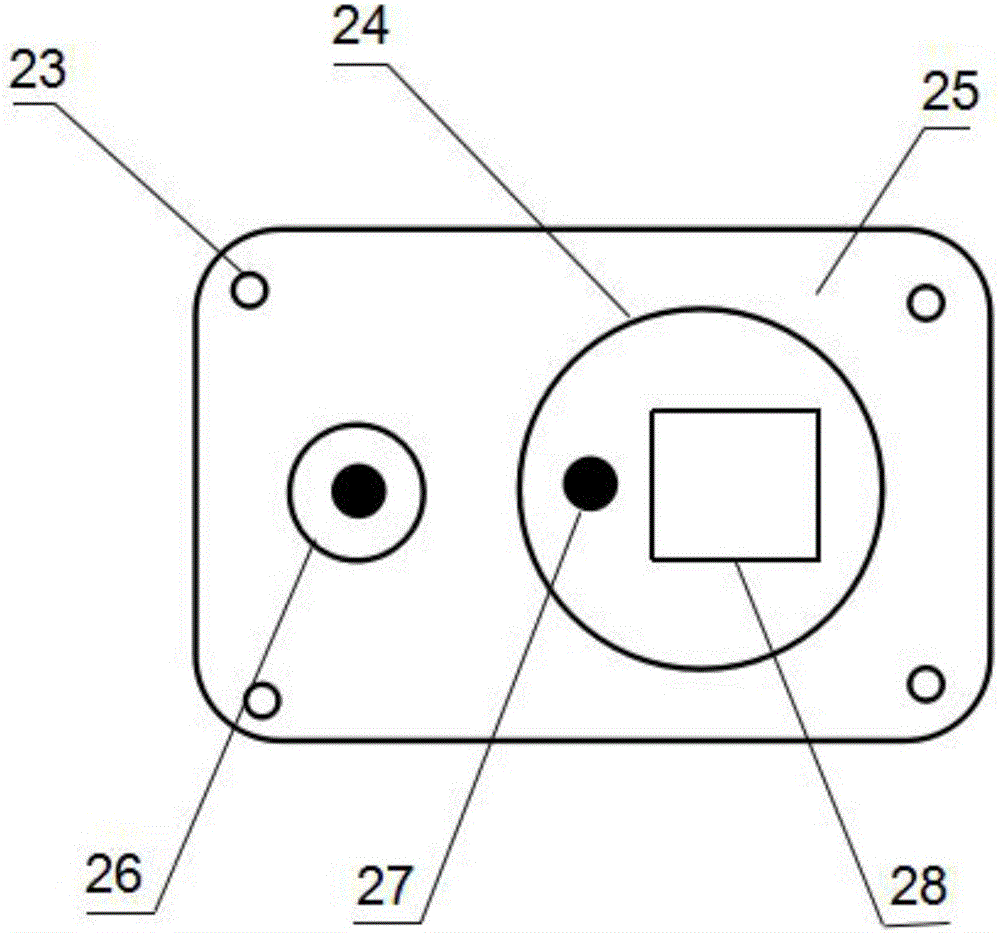

[0018] Such as figure 1 As shown, the device includes fine adjustment knob 1, support frame 2, electrode probe one 3, electrode probe two 4, ammeter 5, water bath 6, stage 7, fine adjustment lifting column 8, aqueous solution 9, annular platinum Electrode wire 10, coarse adjustment knob 11, lifting controller 12, liquid level controller 13, coarse adjustment lifting column 14, transparent observation cover 15, temperature probe 16, air vent 17, experimental container 18, level adjustment bolt 19; sample Fixture 20; electrochemical sample lead 21; solid reference electrode lead 22; screw 23; 24-ring platinum electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com