Chargeable shell lithium ion battery

A lithium-ion battery and hard-shell technology, which is applied in the field of rechargeable hard-shell lithium-ion batteries, can solve the problems of large force, occupation, and small pulling force of positive and negative pole pieces, so as to improve the number of charge and discharge, reduce production costs, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

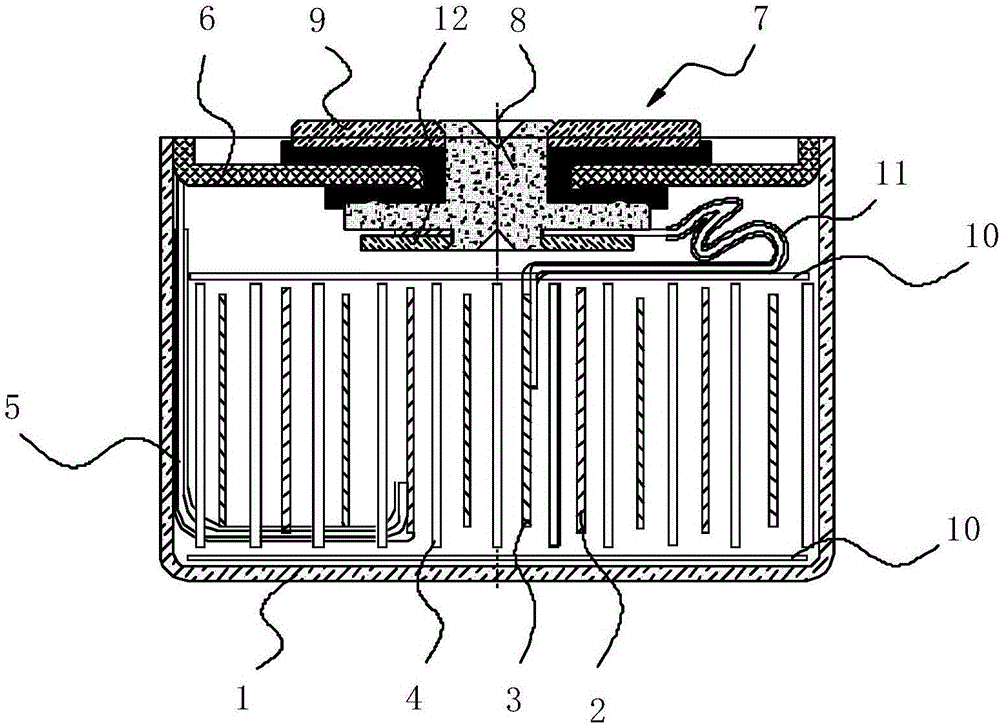

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

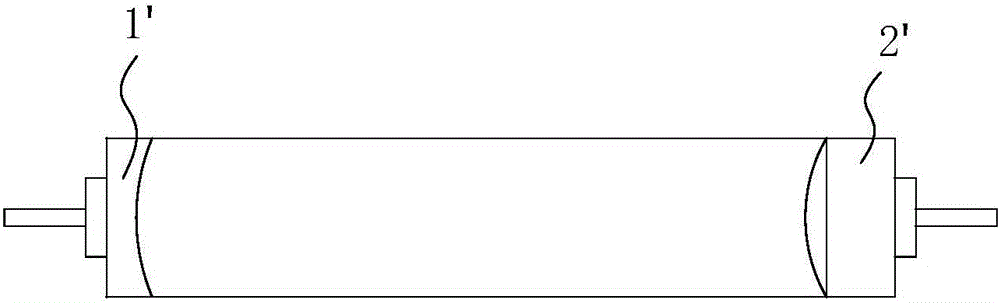

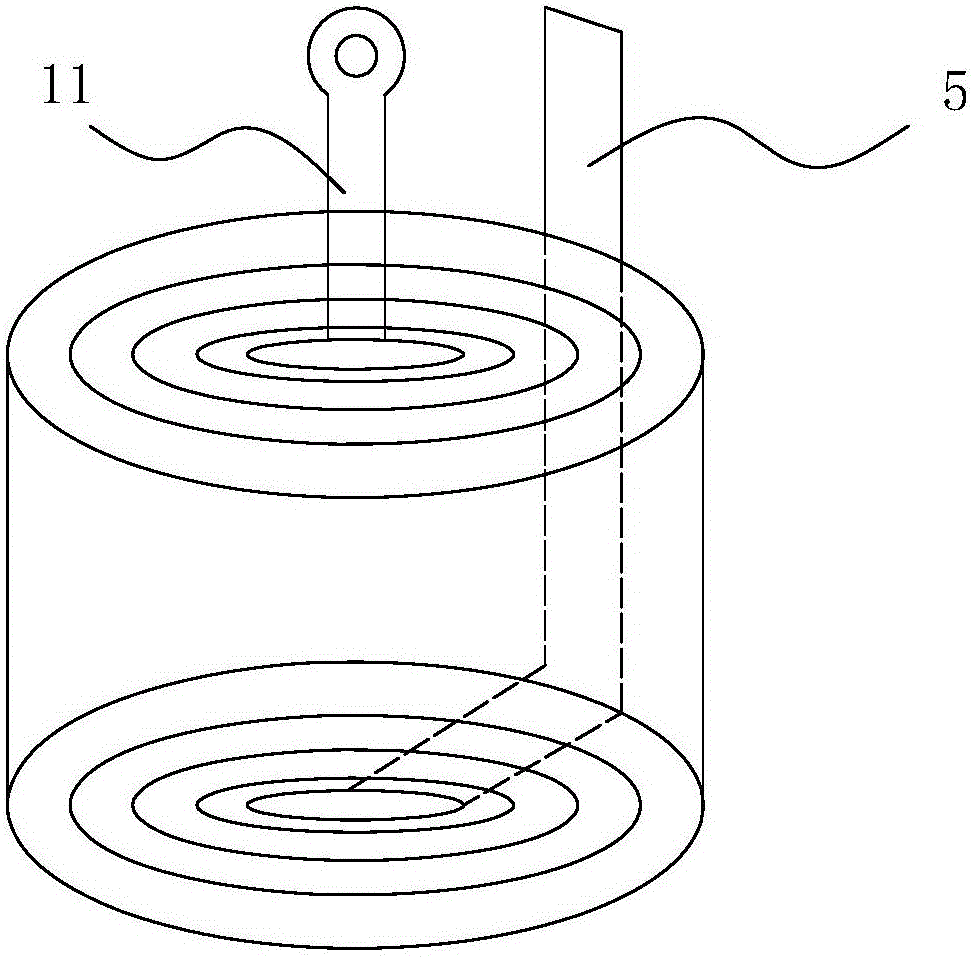

[0029] Such as Figure 2-4 As shown, in this embodiment, a rechargeable hard shell lithium-ion battery according to the present invention includes a positive electrode assembly and a negative electrode assembly, the positive electrode assembly and the negative electrode assembly are insulated from each other, and a winding is formed between the two Body installation space, the winding body installation space is provided with electrolyte and winding body, the winding body is respectively drawn from the position close to the center of the positive pole tab 11 and the negative pole tab 5, the positive pole tab 11 It is electrically connected with the positive electrode assembly, and the negative electrode tab 5 is electrically connected with the negative electrode assembly. The position close to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com