Parallel connection three-terminal direct current power transmission system and power coordination control method of the same

A DC transmission system, coordinated control technology, applied in the direction of power transmission AC network, etc., can solve the problem of high investment cost, achieve the effect of increasing reserve capacity, increasing smoothing reactor, and suppressing DC line faults

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the drawings.

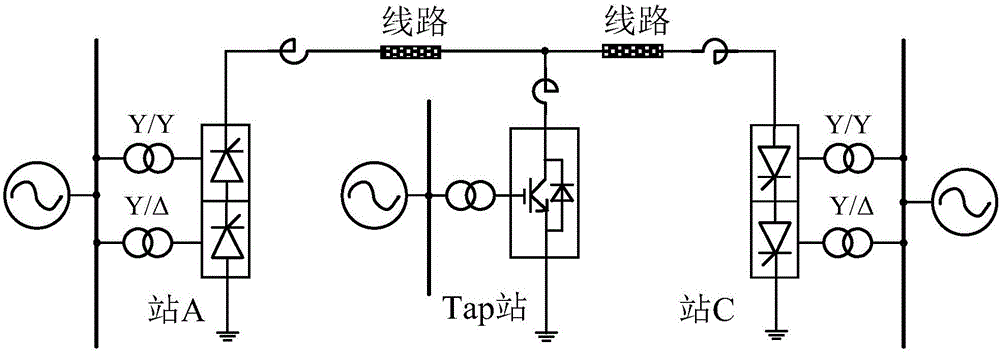

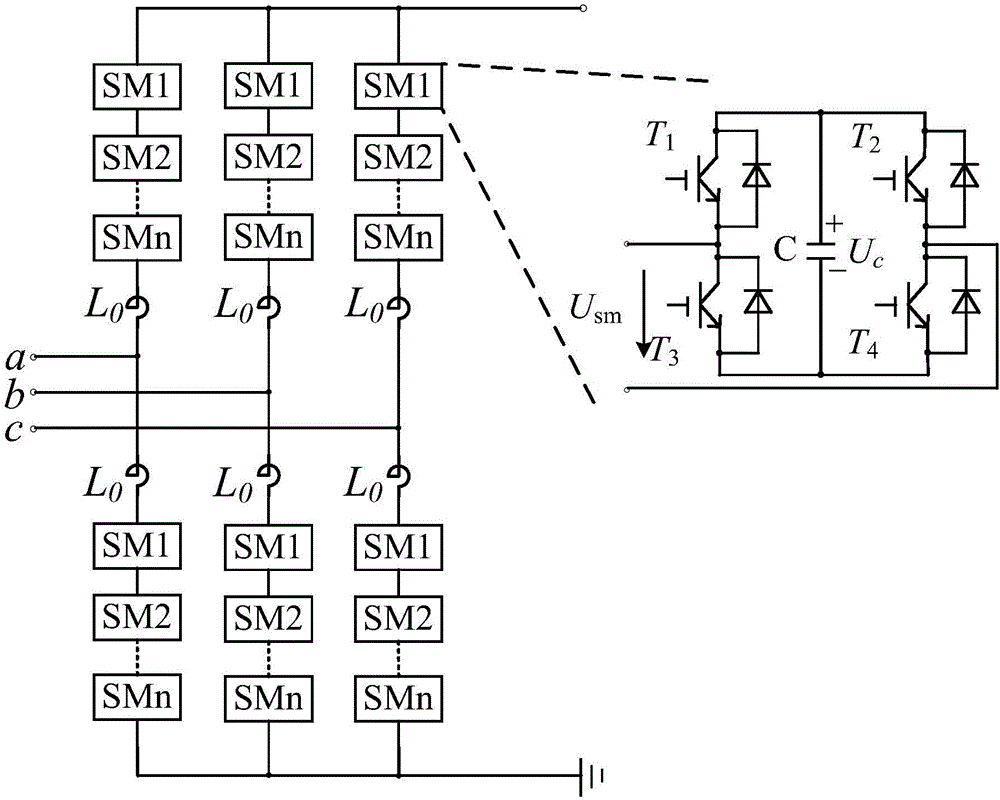

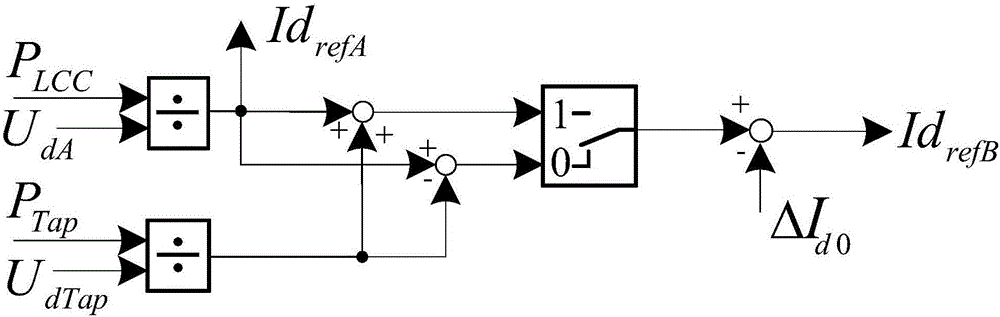

[0018] Such as figure 1 As shown, the parallel three-terminal DC transmission system provided by the present invention includes two power grid commutated current source converters (Line-Commutated Converter, LCC), LCC converters and other corresponding equipment to form a converter station, respectively For station A and station C, station A corresponds to the first LCC converter, and station C corresponds to the second LCC converter. A DC transmission line is connected between the DC side of station A and the DC side of station C. A power substation B is led out from the DC transmission line. The power substation B is mainly composed of a voltage source converter (Voltage Source Converter, VSC) composition. Such as figure 2 As shown, the VSC converter is composed of Full Bridge Modular Multilevel Converter (FB-MMC). The converter station A, station B and station C formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com