Package structure and manufacturing method thereof

A technology of packaging structure and manufacturing method, which is applied to electrical components, impedance networks, etc., can solve the problems of poor packaging structure stability, device failure, and large volume of the acoustic wave reflection layer, so as to simplify the packaging process, reduce packaging costs, and reduce volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

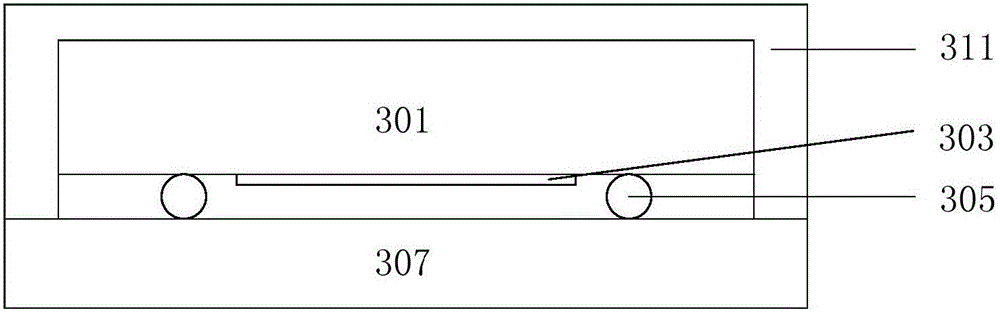

[0033] see Figure 3a , which is the first embodiment of the packaging structure of the present application. The substrate 301 with the device 303 is flip-chip soldered on the substrate 307 , and the metal bump 305 is used to electrically lead the pins of the device 303 to the substrate 307 . The substrate is, for example, a semiconductor substrate such as silicon, or a piezoelectric crystal substrate such as lithium tantalate or lithium niobate. The device 303 is, for example, a surface acoustic wave device or a bulk acoustic wave device. The metal bump 305 is, for example, made of gold, tin, silver, copper or alloys thereof. The substrate 307 is, for example, a resin substrate for packaging. The first encapsulation layer 311 tightly wraps the substrate 301 , and combines with the substrate 307 to form a sealing structure surrounding the substrate 301 and the device 303 . The sealing structure has a cavity in it. The first encapsulation layer 311 may be a single-layer fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com